Small Glass Beveling Machine Uses and Benefits

The primary small glass beveling machine uses are found in artisanal and custom fabrication environments where precision decorative work on smaller glass pieces is required. These compact yet powerful machines are essential tools for stained glass artists, custom frame makers, and producers of decorative objects. They provide the capability to create a high-value, brilliant beveled edge on a scale that is impractical for large industrial equipment. This guide explores the key uses, benefits, and operational principles of these specialized machines. It explains how they empower small workshops to produce work of exceptional quality and creative distinction.

What Defines a Small Glass Beveling Machine?

A small glass beveling machine is a compact piece of equipment designed specifically for creating angled, polished edges on small-scale glass pieces. Unlike its massive industrial counterparts, this machine is characterized by its smaller footprint, lower production volume, and greater emphasis on manual control and versatility for intricate work. It is an accessible entry point into the world of decorative glass finishing. It provides professional-grade results for specialized, low-volume applications.

How Does it Differ from Industrial Machines?

A small glass beveling machine differs from large, industrial machines in several key areas.

- Size and Footprint: The most obvious difference is its compact size. It is designed to fit within a small studio or workshop, whereas an industrial machine may require a significant portion of a factory floor.

- Capacity: These machines are built to handle smaller pieces of glass, often held and guided by hand, rather than the large, automated sheets processed by industrial equipment.

- Speed and Volume: Their production speed is much lower. They are designed for precision on individual pieces rather than the high-throughput of a production line.

- Cost: The capital investment for a small beveler is a fraction of the cost of a large, fully automatic machine. This makes the technology accessible to small businesses and individual artisans.

What Are its Core Operational Principles?

The core operational principles of a small beveler are identical to those of a large machine, just on a smaller scale. The process involves a sequential application of grinding and polishing. The glass edge is first ground to the desired angle using a coarse diamond wheel. It is then smoothed with a series of progressively finer wheels. Finally, a felt wheel with a cerium oxide slurry is used to create the brilliant, transparent polish. This systematic approach is detailed in our guide on how glass beveling machines work.

Who is the Ideal User for This Type of Machine?

The ideal user for a small glass beveling machine is a craftsman, artist, or small business owner who produces custom, high-value glass products. This includes stained glass studios creating beveled components, custom picture framers offering premium options, and artisans who make decorative glass objects like jewelry boxes or awards. It is for the user who values precision and creative control over mass production speed. It empowers them to add a premium finish to their work in-house.

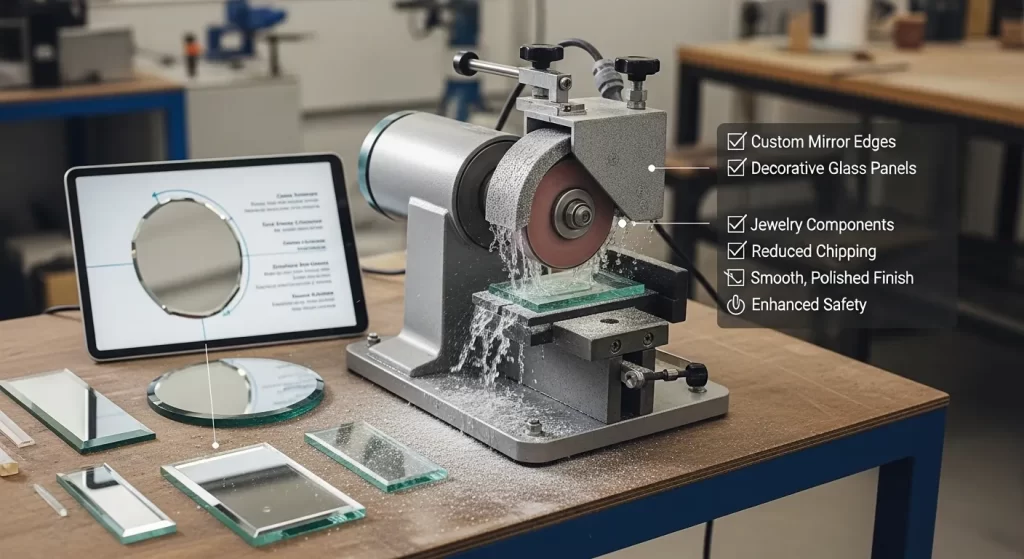

What Are the Primary Small Glass Beveling Machine Uses?

The primary small glass beveling machine uses are concentrated in niche markets that demand custom decorative glasswork. These machines are not for producing large architectural panels. They are the precision tools behind the intricate, sparkling details found in art glass, custom decor, and personalized awards. Their value lies in their ability to handle small, often complex pieces with a high degree of control.

How is it Used in the Stained Glass and Art Glass Industry?

In the stained glass industry, a small beveler is an indispensable tool. It is used to create beveled glass clusters. These are arrangements of individual, hand-beveled pieces that are then assembled into a larger panel using lead or copper foil. Beveling these small, often curved pieces adds a brilliant, jewel-like quality to the finished window or suncatcher. This cannot be achieved with flat glass alone. The machine allows artists to create their own custom bevels. This provides more creative freedom than relying on pre-made beveled components.

What is its Role in Crafting Custom Mirrors and Picture Frames?

A small beveler plays a key role in the high-end custom framing market. It allows a frame shop to offer a premium beveled edge on custom-cut mirrors and the glass for picture frames. A beveled mirror has a more sophisticated, finished look. A beveled edge on the glass of a picture frame can add a subtle, elegant border that enhances the artwork within. The ability to offer this custom service in-house is a significant competitive advantage. It elevates the workshop beyond simple glass cutting.

How Does it Benefit the Production of Glass Awards and Trophies?

This machine is a cornerstone of the awards and recognition industry. A glass award with multi-faceted, beveled edges has a substantial and premium feel. The beveled surfaces catch and refract light. This creates a brilliant sparkle that signifies quality and prestige. A small beveling machine allows for the creation of custom-shaped awards. It also enables the beveling of thick glass blanks to create a sense of depth and dimension. This is a key process for producing high-value corporate and sporting trophies.

What Are its Applications in Jewelry and Decorative Objects?

The applications extend to the creation of fine decorative objects. Artisans use these machines to bevel the edges of small glass pieces used in:

- Jewelry: Creating faceted glass pendants and components for earrings.

- Decorative Boxes: Beveling the glass panels for high-end jewelry boxes and display cases.

- Coasters and Ornaments: Adding a finished, decorative edge to custom glass coasters, ornaments, and other giftware. The machine's ability to handle very small pieces safely and precisely is what makes these applications possible. It turns simple glass shapes into refined, finished products.

What Are the Key Benefits of Using a Small Beveling Machine?

The key benefits of investing in a small glass beveling machine are significant for a small business or studio. They extend beyond the simple ability to create a beveled edge. The benefits are strategic. They include access to more profitable markets, operational efficiency within a small workspace, and unparalleled creative freedom. It is an investment in capability that can fundamentally change a workshop's market position.

How Does it Provide Access to a High-Value Market?

A small beveling machine provides direct access to a high-value market because beveled glass is a premium product. A beveled edge is a recognized sign of quality and luxury. It allows a business to command a higher price for its products. A custom-beveled mirror will sell for significantly more than a plain one. A stained glass panel with hand-beveled elements is a higher-value art piece. The machine is a tool that enables a business to add significant value to a low-cost raw material. The use of beveling glass for interior design is a growing trend that a small workshop can capitalize on.

What is the Advantage of its Compact Footprint?

The advantage of its compact footprint is a practical and economic one. Floor space is often a major constraint in a small workshop or artist's studio. A small, benchtop beveling machine occupies minimal space. This allows a business to add a significant new capability without requiring a major expansion or workshop reorganization. This space efficiency is a key design feature. It makes advanced finishing technology accessible to businesses that could never accommodate a large, industrial machine.

How Does it Offer Cost-Effective Entry into Beveling?

A small beveling machine offers a cost-effective entry point into professional glass finishing. The capital investment required is a fraction of that for a large, automated machine. This lower barrier to entry allows a small business to begin offering premium beveled products. They can then build their market and skills. The machine can pay for itself relatively quickly through the higher profit margins on beveled products. It is a financially manageable step toward greater capability. The ROI can be very attractive for a business with a clear market for decorative glass.

How Does it Empower Creative Customization?

A small beveling machine empowers creative customization by putting the entire process in the hands of the artisan. The user is not limited to standard, mass-produced beveled shapes. They can cut any shape they desire and then apply a perfect bevel to it. This allows for the creation of truly unique, one-of-a-kind pieces. This level of customization is highly valued in the art and custom decor markets. It is a key differentiator that separates a craftsman from a simple reseller. It enables a level of artistic expression that is its most profound benefit.

How Does a Small Glass Beveling Machine Work?

A small glass beveling machine works by using a series of rotating abrasive wheels to shape and polish the glass edge. While smaller and often more manually operated than their industrial counterparts, they follow the same fundamental, multi-stage process. The operator guides the glass piece against the wheels in a specific sequence to achieve the final, brilliant finish. A deep understanding of this process is essential for producing high-quality work.

What is the Sequential Grinding and Polishing Process?

The sequential process is the key to a flawless bevel. It cannot be rushed.

- Rough Grinding: The first step uses a coarse-grit diamond wheel to remove the bulk of the material and establish the bevel's angle. This stage is fast and aggressive.

- Fining/Honing: The next step uses a finer-grit smoothing wheel. This removes the deep scratches left by the grinding wheel. This prepares the surface for polishing.

- Polishing: The final step uses a felt or synthetic polishing wheel. This wheel is charged with a cerium oxide slurry. This chemo-mechanical process creates the final, brilliant shine. This is a core concept for anyone learning how to polish glass edges like a pro.

How is the Glass Handled and Guided?

On most small beveling machines, the glass is handled and guided manually by the operator. The machine has a work surface and guides to help the operator maintain a consistent angle and pressure. The operator holds the piece of glass firmly and moves it smoothly across the face of the rotating wheels. This requires a steady hand and a consistent motion to achieve a uniform bevel. Some more advanced small machines may have jigs or fixtures to assist in guiding the glass, especially for straight edges.

What are the Key Components and Controls?

The key components of a small beveler are the motor, the spindles or arbors that hold the wheels, the coolant system, and the operator controls. The motor must be powerful enough to maintain a constant speed under load. The spindles must be high-quality and run true, without any wobble. The coolant system, often a simple water drip or recirculation pump, is crucial for preventing heat buildup. The controls are typically straightforward. They include an on/off switch and sometimes a speed control for the motor.

How Does it Handle Straight vs. Shaped Pieces?

A small beveler handles straight and shaped pieces differently. For straight edges, the operator can use a guide or fence on the machine's work table to ensure a perfectly straight pass. For curved or shaped pieces, the operator must guide the glass freehand. They follow the contour of the curve against the wheel. This requires a high level of skill and practice. This distinction between the techniques for different geometries is a key concept in understanding glass shape beveling vs. straight beveling.

What Are the Essential Techniques for Professional Results?

Achieving professional results on a small glass beveling machine requires more than just owning the equipment. It requires the development of skill and a commitment to a methodical process. Mastering the techniques of consistency, proper tool maintenance, and safety is what elevates the work from amateur to professional quality. This is the hands-on aspect of glass beveling and edging mastery.

How Do You Ensure a Consistent Bevel Width and Angle?

Ensuring consistency requires a combination of proper machine setup and skilled operator technique. The guides on the machine should be set accurately. The operator must then focus on applying even, consistent pressure as they move the glass across the wheel. They must also maintain a constant feed speed. Any hesitation or change in pressure will be visible in the final bevel. Practice and muscle memory are key to developing this consistency.

What is the Importance of Proper Tooling and Maintenance?

Proper tooling and maintenance are critical. The diamond and polishing wheels must be of high quality. They must also be well-maintained. Diamond grinding wheels need to be "dressed" periodically. This process removes the glazed-over surface and exposes fresh, sharp diamonds. The coolant system must be kept clean and free of excessive glass slurry. A clogged coolant line can lead to immediate overheating and a ruined piece of glass. These maintenance steps are the best way to prevent the issues detailed in our guide to common beveling problems and solutions.

How Do You Achieve a Flawless Polish?

Achieving a flawless polish is the final test of skill. It requires a perfectly prepared surface from the fining stage. The polishing wheel must be clean and in good condition. The cerium oxide slurry must have the correct concentration. The operator must use a light, consistent pressure. Too much pressure will generate excess heat. It will not result in a better polish. The process is one of finesse, not force. It requires patience and attention to detail.

What Safety Precautions Are Necessary?

Safety precautions are non-negotiable. The operator must always wear safety glasses with side shields to protect against spray and glass chips. Waterproof gloves are needed to protect the hands. A waterproof apron is also recommended. The work area must be kept clean to prevent slips on the wet floor. The operator must be trained on how to handle the small glass pieces safely to avoid cuts. All of these practices are covered in our guide on how to polish the edge of glass safely.

How Does a Small Beveler Compare to Other Edging Tools?

A small beveler is a specialized, decorative tool. It is important to understand how it compares to other, more common glass edging tools. Its purpose is distinct from that of a basic sander or a standard edger. Choosing the right tool depends on the desired final finish of the glass edge.

How is Beveling Different from Basic Edge Sanding?

Beveling is a world apart from basic edge sanding. The goal of a glass edge sanding machine is simply to make the glass safe to handle. It lightly abrades the sharp corners, leaving a matte, opaque finish. Beveling is a multi-stage decorative process. It is designed to create a brilliant, optically clear angled surface that refracts light. One is a basic safety measure; the other is a high-end decorative art form.

What is the Distinction Between Beveling and Standard Edging?

The distinction between beveling and standard edging is a key concept. Standard edging, like a flat polish, works on the narrow perimeter or thickness of the glass. Its goal is to create a safe and aesthetically pleasing profile. Beveling works on the face of the glass. It creates an angled surface that is purely decorative. The article glass beveling vs edging difference provides a detailed comparison of these two premium finishing processes.

When Should You Choose a Beveler Over a Standard Edger?

You should choose a beveler when the primary goal is decoration. If the design calls for a brilliant, prismatic effect to enhance the beauty of the glass, then a bevel is the correct choice. You should choose a standard edger when the primary goal is a clean, safe, and functional finish for a product like a shower door or a shelf. The guide on how to choose the best glass edger can help a workshop decide which type of machine aligns with its primary product line.

Conclusion

The many small glass beveling machine uses demonstrate that a compact tool can have a major impact on a workshop's capabilities and profitability. This specialized equipment empowers artisans and small businesses to create high-value, decorative products that stand out in the marketplace. From the intricate components of a stained glass window to the brilliant facets of a custom award, the small beveler is a key to unlocking creative potential. By providing a cost-effective and space-efficient way to achieve a professional-grade beveled finish, it proves that a big impact often comes in a small package.