Laser Glass Etching Machines: Your 2025 Guide to Stunning Designs

Ever admired a glass etched with a delicate pattern and wondered how it was crafted? Maybe it was a personalized tumbler from a craft fair or a frosted office partition that screamed sophistication. Laser glass etching machines are the artists behind those creations, transforming plain glass into custom masterpieces with incredible precision. In 2025, these machines are more accessible than ever, letting hobbyists, small businesses, and industrial fabricators create everything from custom glassware to architectural decor. Companies FUJIAN BAINENG are leading the way with cutting-edge tech that makes etching glass a breeze.

In this guide, I’ll walk you through everything you need to know about laser glass etching machines. We’ll cover how they work, the best models for your projects, creative applications, and tips to nail your etches. I’ll also compare laser etching to sandblasting to help you pick the right method. By the end, you’ll be ready to start etching glass like a pro. Let’s jump in!

How Does a Laser Glass Etching Machine Work?

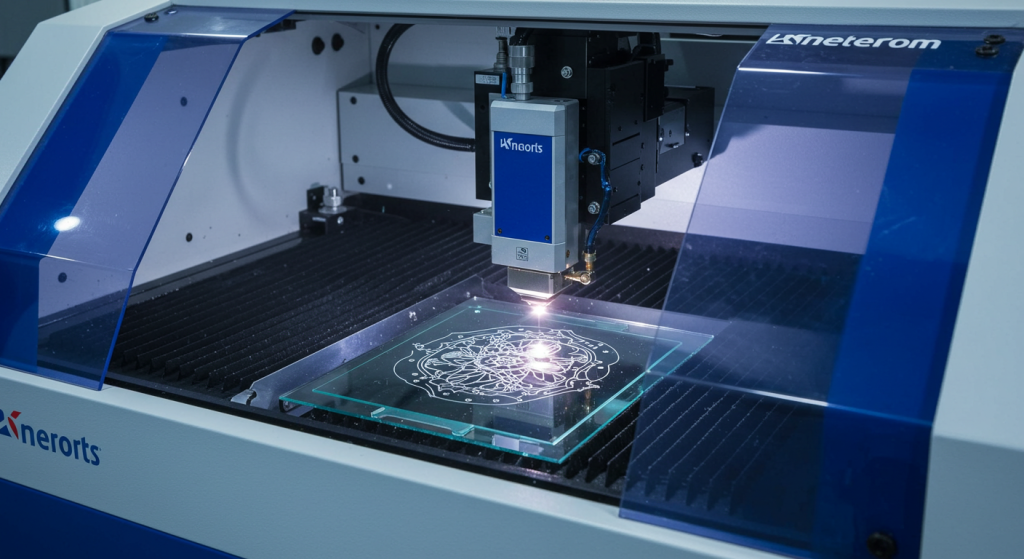

Picture a laser glass etching machine as a high-tech pen that draws on glass with light. It uses a focused laser beam—typically from a CO2 or UV laser—to create tiny fractures or vaporize the glass surface, leaving a frosted, etched design. Since the laser doesn’t touch the glass, there’s no risk of cracking delicate pieces, which is a huge advantage, as explained by xTool. The result is a permanent, smooth etching, whether it’s a logo, text, or intricate pattern.

The process starts with your design, crafted in software like LightBurn. You upload it, adjust settings like power and speed, and place your glass in the machine. For curved items like bottles, a rotary attachment spins the glass to keep the laser focused. The laser traces the design, etching it in minutes. For example, a 40W CO2 laser can etch a 50x50mm logo in 2-5 minutes, per OMTech. A damp paper towel on the glass can reduce heat and create brighter, smoother etches, a trick shared by Trotec.

Glass forms micro-cracks for that frosted look, unlike wood or metal. FUJIAN BAINENG’s Glass Laser Etching Machine elevates this with CNC precision, offering 2D and 3D engraving for complex designs on glassware or panels, backed by CE/ISO certification for quality. After etching, a quick rinse removes residue, and your design is ready to shine.

Laser Etching vs. Sandblasting: Which Is Right for You?

You might be curious how laser etching compares to sandblasting, another popular way to etch glass. Both create frosted designs, but they’re suited to different needs. Let’s break it down.

Sandblasting uses high-pressure abrasives, like aluminum oxide, to carve into glass through a stencil. It’s ideal for deep etches (up to 1mm) and large surfaces, like frosted privacy panels, producing a smooth, premium finish, as noted by Delphi Glass. But it’s messy, requires a compressor, cabinet, and protective gear, and takes longer due to setup and cleanup.

Laser etching is cleaner and more precise, excelling at fine details like logos or text with resolutions up to 1200 DPI, per TechRadar. It skips stencils and works in small spaces, but it’s limited to surface etching (0.01-0.1mm) and may have a less sharp finish than sandblasting, as highlighted by OMTech.

Here’s a comparison table to clarify:

| Feature | Laser Etching | Sandblasting |

|---|---|---|

| Precision | High (up to 1200 DPI) | Moderate (stencil-based) |

| Setup | Laser machine, software, small space | Compressor, cabinet, abrasives, gear |

| Speed | Fast (2-5 min for small designs) | Slower (10-20 min with setup) |

| Depth | Surface (0.01-0.1mm) | Deep (up to 1mm) |

| Cost | $500-$50,000 (machine) | $1,000-$6,000 (setup) |

| Best For | Detailed designs, small projects | Large areas, deep textures |

For intricate, custom work, laser etching—especially with machines like BAINENG’s—is your best bet. For deep, uniform etches on large glass, sandblasting might be the way to go, per Glass Etching Fever.

Types of Laser Glass Etching Machines

Choosing the right laser etching machine depends on your projects and budget. Here’s a rundown of the main types for glass in 2025:

CO2 Laser Etching Machines

CO2 lasers (40W-150W) are the most popular for glass, creating frosted etches on flat or curved surfaces. Models like the xTool P2 (55W) or Glowforge Pro handle glassware to panels, with beds up to 495x279mm, costing $2,000-$5,000, per CNET.

UV Laser Etching Machines

UV lasers (3W-5W), like the ComMarker Omni 1, use minimal heat for ultra-fine etches, ideal for delicate glass or high-contrast designs. They’re pricier ($5,000-$10,000) but excel at precision work, per Hobby Laser Cutters.

Diode Laser Etching Machines

Diode lasers (5W-20W), like the Longer Ray5, need pre-treatment (e.g., paint or marking paper) to etch glass, as their 450nm wavelength passes through clear glass. They’re budget-friendly ($500-$1,000) for small projects, per Tom’s Hardware.

Industrial Laser Etching Machines

Industrial CO2 or UV lasers, like the Epilog Fusion Pro 48 or FUJIAN BAINENG’s CNC Glass Engraving Machine, offer large beds (1200x900mm) and high speeds for mass production. They cost $20,000-$50,000 and excel at 2D/3D designs, per STYLECNC.

Desktop Laser Etching Machines

Desktop CO2 or diode models, like the Ortur Laser Master 3, fit small spaces and etch glassware or panels up to 400x400mm. They’re beginner-friendly, costing $800-$2,000.

A 40W-60W CO2 laser with a rotary attachment is ideal for most glass etching, balancing power and affordability, per Thunder Laser.

Creative Applications for Laser Etched Glass

Laser etching on glass opens up endless possibilities. Here are some ideas to spark your creativity:

- Custom Glassware: Etch names, dates, or logos on wine glasses or mugs for weddings or corporate gifts. A set can sell for $20-$50 on Etsy.

- Privacy Panels: Create frosted patterns on windows or shower doors for stylish privacy, like logos or geometric designs for offices.

- Awards and Trophies: Etch glass plaques with text or logos for events, adding a premium touch, per Epilog.

- Home Decor: Engrave vases, frames, or candle holders with floral or abstract patterns. An etched frame can fetch $50-$200.

- Photo Etchings: Transfer grayscale photos onto glass for keepsakes, a technique detailed by Monport.

- Coasters and Ornaments: Etch glass coasters or pendants with monograms for boutique sales.

These applications show how laser etching can transform glass into unique, high-value products.

Benefits of Laser Glass Etching Machines

Why choose a laser etching machine for glass? Here’s what sets it apart:

- High Precision: Up to 1200 DPI captures fine details, like text or photos, better than sandblasting’s stencil limits.

- Clean Process: No abrasive dust or chemicals—just a quick rinse, unlike sandblasting’s mess, per JustLaser.

- Speed: Small designs etch in 2-5 minutes, speeding up production compared to sandblasting’s 10-20 minutes.

- Safe for Thin Glass: Non-contact etching reduces cracking risks on 0.5-3mm glass, per xTool.

- Durable Designs: Etchings resist wear, fading, or washing, perfect for daily-use glassware.

- Eco-Friendly: No abrasives or acids mean a greener process.

These perks make laser etching a top choice for professional, hassle-free results.

Tips for Perfect Glass Etchings

To get those stunning etches, follow these tips:

- Choose the Right Glass: Soda-lime (common in bottles) or borosilicate (labware) etch cleanly. Avoid lead crystal, which can crack, per Focused Laser Systems.

- Test Settings: On a 40W CO2 laser, try 20-30% power, 300mm/s speed, and 500 DPI on scrap glass. High power can roughen etches.

- Use Wet Paper Towel: Apply a damp paper towel for bright, smooth etches. Turn off air assist, per Trotec.

- Clean Thoroughly: Wipe glass with isopropyl alcohol to remove dust or oils.

- Optimize Designs: Use high-contrast, black-and-white images or SVG files. For photos, apply a 70% grayscale matrix and “Ordered Dithering” in LightBurn, per Monport.

- Secure the Glass: Tape flat glass or use a level rotary attachment for curved items.

Practice on cheap glass to master settings before tackling big projects.

Choosing the Right Laser Glass Etching Machine

Here’s how to pick the perfect machine:

- Project Scale: For glassware or small decor, a desktop CO2 laser like the xTool P2 or Glowforge Pro is ideal. For large panels or bulk work, consider BAINENG’s CNC Glass Engraving Machine or Epilog Fusion Pro.

- Budget: Hobbyists can start with a diode laser ($500-$1,000) with pre-treatment or a CO2 laser ($2,000-$5,000). Businesses may spend $10,000-$50,000.

- Bed Size: Match to your glass—400x400mm for small items, 1200x900mm for panels.

- Rotary Attachment: Needed for bottles or glasses, standard with BAINENG and most CO2 lasers.

- Software: Ensure LightBurn compatibility for easy design control.

- Support: Choose brands like BAINENG, xTool, or Epilog with strong service, per CNCSourced.

A 40W CO2 laser with a rotary attachment is a great starting point for most glass etching.

Maintenance and Safety Tips

Keep your machine in top shape and stay safe with these tips:

- Clean Optics: Wipe lenses and mirrors weekly with isopropyl alcohol to maintain beam clarity, per OMTech.

- Check Cooling: Ensure water cooling (CO2 lasers) or fans (diodes) are clear to avoid overheating.

- Ventilate: Use a fume extractor or vent to remove glass dust and fumes.

- Safety Gear: Wear laser safety glasses for open-frame lasers (Class 4); enclosed lasers (Class 1) are safer.

- Avoid Over-Etching: Multiple passes can crack glass due to heat, per Focused Laser Systems.

- Inspect Parts: Check belts, rails, and rotary attachments monthly for wear.

Regular maintenance ensures consistent, high-quality etches.

FAQs About Laser Glass Etching Machines

Can I etch any glass type?

Most glass—soda-lime, borosilicate, tempered—etches well. Avoid lead crystal, which may crack under laser heat, per Focused Laser Systems.

How deep are laser etches?

CO2 lasers etch 0.01-0.1mm; UV lasers reach 0.1-0.2mm for finer work, per Thunder Laser.

Do I need special software?

LightBurn or RDWorks are ideal for precise control, supporting vectors and photo etching.

Is it safe for thin glass?

Yes, non-contact etching reduces cracking if you use low power and test settings, per xTool.

How long does etching take?

Small designs (50x50mm) take 2-5 minutes; larger patterns may need 10-30 minutes, per OMTech.

Conclusion

Laser glass etching machines are your ticket to creating personalized, high-value designs that stand out. From custom glassware to frosted decor, they offer precision and speed that sandblasting can’t always match, especially for detailed work. A 40W CO2 laser or FUJIAN BAINENG’s CNC Glass Engraving Machine is a fantastic starting point, and tricks like the wet paper towel can elevate your etches. Start small, experiment with settings on scrap glass, and watch your creations shine in 2025.