How to Choose the Best Glass Edger for Results

Learning how to choose the best glass edger is a critical strategic decision for any glass fabrication workshop. This choice is a significant capital investment that will directly influence product quality, production efficiency, and overall profitability for years to come. The "best" machine is not a one-size-fits-all solution. It is the machine that is perfectly aligned with a workshop's specific production needs, product mix, and long-term business goals. This definitive guide provides an expert framework for making this crucial decision. It covers the essential analysis, key specifications, and strategic considerations required to select the ideal machine for achieving professional, high-quality results.

What is the Core Principle of Choosing the Best Glass Edger?

The core principle of choosing the best glass edger is to match the machine's capabilities directly to your workshop's specific requirements. This process begins with a thorough internal analysis of your production needs before ever looking at a single machine. The best edger is the one that efficiently and reliably produces the edge profiles you need, at the volume you require, and with the quality your customers demand. It is a decision driven by data and strategy, not by features alone.

How Does the "Best" Machine Vary for Different Workshops?

The "best" machine for a high-volume mirror manufacturer is completely different from the "best" machine for a custom, low-volume furniture maker. The mirror manufacturer needs a high-speed, durable straight-line edger. The custom furniture maker needs a flexible CNC machine that can handle unique shapes. There is no single "best" machine on the market. There is only the best machine for your specific application. A successful choice is a direct reflection of a clear business strategy.

Why is a Needs Analysis the Critical First Step?

A needs analysis is the critical first step because it provides the data needed to make an informed decision. Without this analysis, a buyer is simply guessing. This internal audit should quantify your production volume, define your most common products, and list the specific edge profiles you need to create. This data-driven approach removes emotion and marketing hype from the equation. It allows you to create a checklist of essential requirements that any potential machine must meet.

How Do You Analyze Your Workshop's Production Needs?

Analyzing your workshop's production needs is a systematic process. It involves a detailed examination of what you make, how much you make, and the materials you use. This introspective step is the most important part of the entire selection process. It creates the framework for every subsequent decision. A clear understanding of your needs will prevent you from overspending on unnecessary capabilities or underspending on a machine that cannot meet your future demands.

What is the Importance of Defining Your Product Mix?

Defining your product mix is crucial because different products require different machine capabilities. You must list out your primary products. Are you making:

- Rectangular mirrors and shelves?

- Frameless shower doors with notches?

- Custom-shaped tabletops and architectural panels?A workshop that primarily produces rectangular products will have different needs than a shop that specializes in custom shapes. This analysis will be the primary factor in deciding between a straight-line machine and a shape (CNC) machine.

How Do You Assess Your Production Volume?

Assessing your production volume determines the required speed and level of automation. A low-volume, high-customization shop may prioritize flexibility over raw speed. A high-volume production facility, however, needs a machine built for speed and continuous operation. You should quantify your output. How many linear meters of glass do you edge per day or per week? This number will help you evaluate a machine's stated production capacity and determine if it can meet your demands.

What Are the Key Material Considerations?

The key material considerations are the size and thickness of the glass you typically work with. The machine you choose must have a workbed or conveyor that can accommodate the largest pieces of glass you handle. It must also have spindles and motors that are powerful enough to process the thickest glass you use. It is wise to choose a machine with a capacity slightly larger than your current needs. This provides a buffer for future growth and allows you to take on larger, more lucrative projects.

How to Determine the Required Edge Profiles?

You must determine the specific edge profiles you need to produce. The most common are the flat polish and the pencil polish. Do your products require more complex profiles like an ogee or a waterfall edge? Do you need to offer decorative finishes like beveling? The desired edge profiles will dictate the type and number of wheels the machine must have. A machine with more spindles offers greater flexibility. It can produce a wider range of profiles and a higher quality finish. This is a key aspect of glass beveling and edging mastery.

What Are the Main Types of Glass Edging Machines?

Glass edging machines are broadly categorized into three types. These are straight-line edgers, shape (CNC) edgers, and smaller manual sanders. Each is designed for a different scale and type of work. The straight-line machine is the production workhorse for rectangular glass. The CNC edger is the versatile artist for custom shapes. The manual sander is the basic tool for safety seaming.

What is a Straight-Line Glass Edging Machine?

A straight-line glass edging machine is designed for the high-speed, high-volume production of flat polished or other profiles on the straight edges of rectangular glass. It operates like an assembly line. The glass is fed on a conveyor past a series of fixed-position grinding and polishing wheels. These machines are the industry standard for manufacturers of mirrors, shelves, and insulated glass units. They are built for speed and reliability.

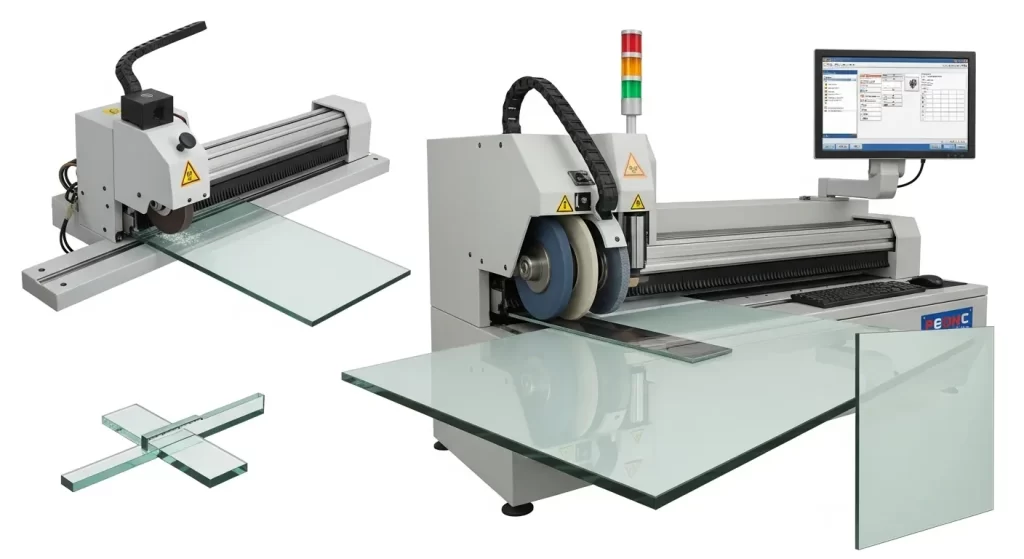

What is a Shape (CNC) Glass Edging Machine?

A shape, or CNC, glass edging machine is designed for flexibility. The glass is held stationary on a table by a vacuum system. A computer-controlled tool head, which holds the various wheels, then moves around the perimeter of the glass. This allows it to create a perfect, polished edge on circles, ovals, and complex custom shapes. It is the ideal choice for custom fabrication shops that produce a wide variety of non-rectangular products. The distinction is detailed in our guide on glass shape beveling vs straight beveling, which shares the same machine principles.

What is a Manual Glass Edge Sander?

A manual glass edge sander is the most basic type of edger. As detailed in our glass edge sanding machine guide, its primary purpose is to create a safe, seamed edge. It uses an abrasive belt to lightly dull the sharp corners of the glass. While it does not produce a decorative polished finish, it is an essential tool for safety and for preparing glass that will be installed into a frame. It is the entry point into glass edge finishing.

How Do the Main Types Compare?

A direct comparison highlights the distinct advantages of each machine type. The best choice is a direct reflection of the workshop's primary business model.

| Feature | Straight-Line Edger | Shape (CNC) Edger |

| Best For | High-volume, rectangular products. | Low-volume, custom-shaped products. |

| Operation | Glass moves, tools are stationary. | Glass is stationary, tools move. |

| Speed | Very High | Slower, but flexible. |

| Versatility | Low (Straight edges only). | Very High (Any shape). |

| Cost | Moderate to High. | High. |

What Are the Critical Machine Specifications to Evaluate?

When you begin to evaluate specific machines, you must look beyond the marketing materials. You need to scrutinize the critical technical specifications. These details of construction and components are the true indicators of a machine's quality, durability, and performance. A professional evaluation focuses on these core engineering elements.

Why is the Machine Frame and Construction So Important?

The machine frame is the foundation of its accuracy. A heavy, rigid frame made from welded and stress-relieved steel is essential. It absorbs the vibrations generated by the high-speed spindles. This prevents "chatter," which can ruin a polished edge. A lighter, bolted-together frame will vibrate more. This will lead to a lower quality finish and premature wear on the machine's components. Do not underestimate the importance of mass and rigidity. The global market for machine tools is built on this principle.

How Does the Number of Spindles Affect Quality?

The number of spindles, or wheel stations, has a direct impact on both the quality of the finish and the production speed. A machine with more spindles can perform a more gradual and refined finishing process. It can dedicate more wheels to the crucial fining and polishing stages. A typical high-quality straight-line edger may have nine or more spindles. A machine with fewer spindles must use more aggressive wheels. This can compromise the final finish. More spindles also allow the machine to run at a faster feed rate.

What Should You Look for in the Conveyor and Clamping System?

The conveyor and clamping system must be robust and precise. It is responsible for moving the glass smoothly and securely. Look for a conveyor track with durable, non-marking pads. The clamping system should apply firm, even pressure without distorting the glass. A high-quality system will use precision-ground guides and a heavy-duty drive chain. Any slop or hesitation in the conveyor will be visible in the final edge finish.

What Defines a High-Quality Control System?

A high-quality control system, typically a PLC (Programmable Logic Controller), is defined by its reliability and ease of use. The controller is the brain of the machine. It manages all the motors, sensors, and operational parameters. The user interface should be intuitive, with a clear touchscreen display. It should allow the operator to easily set the glass thickness, feed rate, and other parameters. A good controller will also provide diagnostic information. This helps to troubleshoot any problems quickly.

How Do You Assess the Machine's Finishing Capabilities?

A machine's true value lies in its ability to produce a flawless finish. This capability is a result of the entire system working together. It involves the quality of the polishing wheels, the efficiency of the coolant system, and the precision of the machine's mechanics. These elements must be evaluated as an integrated system.

What is the Importance of the Polishing Wheel Configuration?

The polishing wheel configuration is critical. A high-quality machine will have multiple dedicated polishing stations at the end of its spindle bank. These stations will use felt or other synthetic polishing wheels. They are designed to work with a cerium oxide slurry. Some machines may have a final "X-Wheel" or rubber-based wheel. This wheel can produce an exceptionally brilliant, "wet-look" shine. The quality and condition of these wheels are a key part of the process, as detailed in our guide on how to polish glass edges like a pro.

How Does the Coolant System Impact the Finish?

The coolant system has a direct impact on the finish. A high-volume, well-filtered coolant supply is essential. It prevents heat buildup, lubricates the wheels, and flushes away abrasive glass particles. A system with poor filtration will recirculate these particles. This will cause scratches and a poor-quality finish. The slurry system for the polishing wheels must also be well-maintained. It needs to keep the cerium oxide at the correct concentration and temperature.

Can the Machine Also Produce Beveled Edges?

Some advanced edging machines, often called "edgers and bevelers," have the capability to produce both standard polished edges and decorative beveled edges. These are typically larger machines with a tilting spindle bank. This versatility can be a significant advantage for a workshop that wants to offer a full range of finishing options. However, these machines are more complex and expensive than a dedicated edger. The article on how glass beveling machines work explains the specific requirements for this process.

What Are the Key Business Considerations Beyond the Machine?

Choosing the best glass edger involves looking beyond the machine itself. There are several critical business considerations that are just as important as the technical specifications. These include the manufacturer's reputation, the availability of after-sales support, and the total cost of ownership over the life of the machine.

Why is Manufacturer Reputation and Support So Critical?

The manufacturer's reputation for quality and after-sales support is a critical factor. A glass edger is a long-term investment. You are not just buying a machine; you are entering into a long-term relationship with the manufacturer. You need to be confident that they will be there to provide technical support, training, and spare parts for many years. Look for a manufacturer with a strong track record and positive reviews from other workshops. The cost of downtime due to poor support can be immense.

How Do You Calculate the Total Cost of Ownership (TCO)?

The total cost of ownership (TCO) is a much more important metric than the initial purchase price. The TCO includes:

- The Purchase Price: The initial cost of the machine.

- Installation and Training: The cost to have the machine professionally installed and your team trained.

- Tooling and Consumables: The ongoing cost of replacement diamond wheels, polishing wheels, and coolant.

- Maintenance and Spare Parts: The projected cost of routine maintenance and any necessary repairs.

- Energy Consumption: The cost of the electricity and compressed air to run the machine.A machine with a lower purchase price but higher maintenance and consumable costs may be far more expensive in the long run.

What is the Importance of Training and Ease of Use?

The importance of training and ease of use cannot be overstated. A machine is only as good as the operator running it. The manufacturer should provide comprehensive, on-site training for your team. The machine's control system should be intuitive and easy to learn. A machine that is overly complex or difficult to operate will lead to errors, lower productivity, and operator frustration. A well-trained and confident operator is the key to getting the most out of your investment.

Conclusion

The process of how to choose the best glass edger is a strategic decision that will shape the future of your workshop. It is a choice that demands careful research, a thorough analysis of your own needs, and a focus on long-term value over short-term cost. By prioritizing build quality, assessing the critical components, and evaluating the manufacturer's support system, you can make an informed investment. The best edger will become a reliable and profitable partner. It will empower you to produce high-quality, perfectly finished glass products that meet the highest standards of your customers.