How CNC Glass Machines Work: A Complete Power Guide (2025)

For centuries, the transformation of glass from a raw, fragile sheet into a finished product of breathtaking precision and beauty was an art form, a craft shrouded in the mystique of the master artisan's skill. The process was slow, painstaking, and fraught with the risk of a single, costly mistake. Today, that world has been irrevocably transformed by one of the most powerful and influential technologies in modern manufacturing: Computer Numerical Control (CNC).

But how does it actually work? How can a cold, unfeeling machine possibly replicate—and in many cases, surpass—the nuanced skill of a human hand on a material as notoriously unforgiving as glass? How does a digital drawing on a computer screen become a perfectly beveled mirror, an intricately engraved door, or a precisely drilled architectural panel?

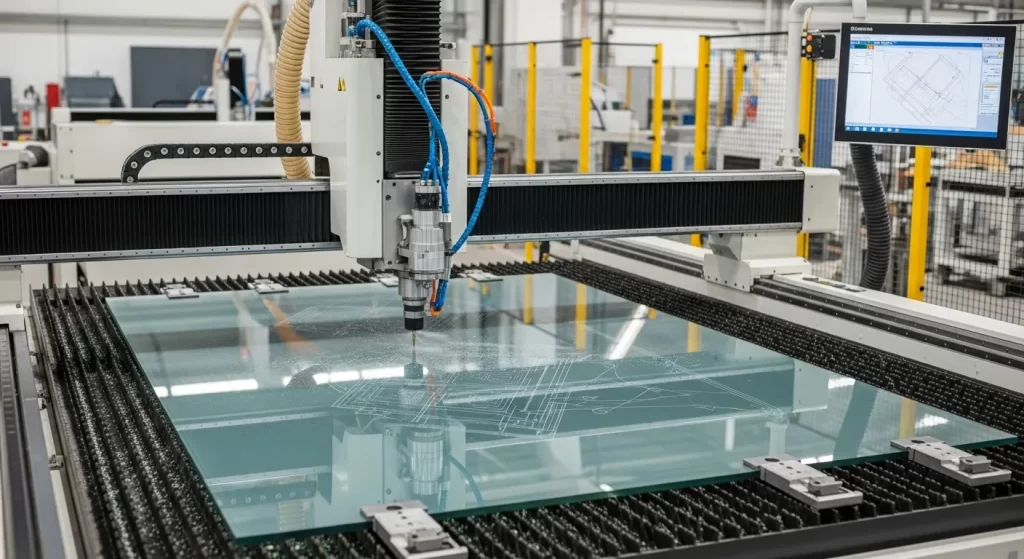

This is your definitive, expert-led power guide to how CNC glass machines work. We will take you behind the control panel and onto the factory floor to demystify the entire process. We will break down the core components of the CNC system, walk you step-by-step through the digital workflow, and explore the specific mechanics of how these incredible machines cut, grind, drill, and polish with a level of precision and speed that has revolutionized the entire glass processing industry.

What is CNC and How Does It Apply to Glass Processing?

CNC, which stands for Computer Numerical Control, is an advanced manufacturing system that uses pre-programmed computer software to precisely and automatically control the movement, speed, and operation of machinery and its tools. In glass processing, this system allows for the automated, incredibly accurate, and perfectly repeatable cutting, edging, beveling, drilling, and polishing of glass, transforming a manual craft into a digital manufacturing process.

Think of the CNC system as the machine's digital brain and central nervous system. It takes a complex digital design and translates it into a precise sequence of mechanical actions. It tells the machine what to do, where to move, how fast to move, and which tool to use at every single step. This is the core principle of modern automation in the glass processing industry.

The Core Components of Any CNC System

Every CNC machine, regardless of its specific function, operates on the same three core components working in harmony. You can explore the foundational principles of this technology on the Computer Numerical Control resource page.

- The Digital Design (CAD/CAM): This is the "blueprint." The process starts with a digital design created in CAD (Computer-Aided Design) software, which is then translated into a machine-readable toolpath by CAM (Computer-Aided Manufacturing) software.

- The Machine Controller (The Brain): This is a dedicated, onboard computer that reads the digital instructions (known as G-code) and translates them into electrical signals.

- The Mechanical System (The Body): The controller sends these signals to a system of powerful motors (servos), actuators, drives, and spindles. This system physically moves the tool head and the glass with extreme precision along multiple axes.

Why is Glass a Unique and Challenging Material for CNC?

Glass is not like metal or wood. Its unique properties present a specific set of challenges that CNC technology is perfectly suited to solve.

- Brittleness: Glass has immense compressive strength but very low tensile strength. A miscalculation in tool pressure or feed rate can cause catastrophic micro-fractures, chipping, or a complete failure of the piece. CNC provides the absolute consistency needed to avoid this.

- Abrasive Nature: Glass dust is extremely abrasive and causes a very high rate of wear on cutting tools. CNC systems can precisely track tool usage and automatically prompt for a replacement, ensuring consistent quality. [Cite a study on the wear rates of diamond tooling in glass machining and the importance of timely replacement for maintaining edge quality].

- Thermal Shock: The friction from grinding and polishing generates a massive amount of heat, which can cause thermal shock and crack the glass. A constant, precisely directed flow of coolant is essential, a task perfectly managed by the CNC system.

The Step-by-Step CNC Glass Processing Workflow: From Design to Reality

The standard CNC glass processing workflow is a seamless, digitally-driven journey that begins with a design on a computer and ends with a perfectly finished physical product. It involves creating a CAD/CAM file, transferring the machine code, setting up the machine and material, and then letting the automated system execute the cutting, shaping, and finishing operations with flawless precision.

Let's walk through the entire process.

Step 1: The Digital Blueprint (CAD/CAM Software)

Everything starts with a digital design. An operator or designer uses CAD software to draw the exact shape of the finished product, specifying every curve, every hole, and every bevel. This CAD file is then imported into CAM software, where the operator assigns the specific tools and operations. For example, they will tell the software to use a 10mm drill bit for a hole, followed by a series of four beveling wheels for the outer edge. The CAM software then intelligently generates the optimal tool path and outputs a G-code file. The software you choose is a key part of how to choose cnc glass machine for workshop.

Step 2: Transferring the "Brain" (G-Code to Controller)

The G-code file, which is essentially a long list of coordinates and commands (e.g., "G01 X50 Y120 Z-2 F2000"), is transferred to the CNC machine's controller via a network connection or a USB drive. The controller reads this code and understands the entire sequence of operations it needs to perform.

Step 3: Machine Setup and Material Securing

This is a critical physical step. The operator securely places the raw sheet of glass onto the machine's worktable. This is typically done using an array of powerful vacuum cups that rise from the table and lock the glass in place, preventing any movement during the high-speed machining process. The operator then tells the machine the precise location of the glass corners, a process known as "referencing" or "homing." This is a key part of any cnc glass working center setup.

Step 4: The Automated "Ballet" of Tool Changing and Execution

Once the program starts, the machine takes over. If the first operation is drilling, the machine's spindle will automatically move to the tool carousel, pick up the correct drill bit, move to the programmed coordinates, and perform the drilling operation. It will then automatically return the drill bit and pick up the next tool needed, for example, a coarse grinding wheel, and begin the next operation. [Cite a statistic on the average time saved per piece by using an automatic tool changer, which can reduce production time by up to 30% on multi-operation jobs].

Step 5: The Lifeblood of the Operation (Coolant)

Throughout the entire machining process, the CNC system directs a high-volume, precisely aimed flow of water or a specialized coolant directly at the point of contact between the tool and the glass. This has two critical functions: it prevents the glass from overheating and suffering from thermal shock, and it washes away the abrasive glass dust, which protects the tool and ensures a clean, smooth finish.

How Does a CNC Machine Perform Specific Glass Operations?

A CNC machine performs a wide variety of specific glass operations by utilizing a carousel of different, highly specialized diamond-impregnated tools. The computer program automatically selects the correct tool for the job—whether it's a cutting wheel, a grinding drum, a drill bit, or a polishing wheel—and controls its speed, feed rate, and path with micron-level precision to achieve the desired result.

Let's look at the mechanics of the most common operations.

How CNC Edging, Grinding, and Beveling Work

These three related processes are the most common CNC functions. They all involve a series of diamond-impregnated wheels of progressively finer grits. The machine makes multiple passes over the edge, starting with a very coarse wheel to do the rough shaping and ending with a very fine wheel to prepare the surface for polishing. Our guide on the difference between cnc glass edging and grinding explains the functional differences, while our article on the benefits of cnc glass beveling machine explores the incredible results.

The Precision of CNC Drilling and Milling

For cnc drilling and milling for glass explained, the machine uses specialized diamond-coated drill bits or milling tools. A key technique for preventing chipping on the exit side of a hole ("breakout") is "peck drilling," where the machine drills partially through, retracts to clear debris, and then continues. The cnc vertical drilling machine advantages are particularly notable for their efficiency in high-volume production.

Achieving a Flawless CNC Polish

After the final fine-grinding stage, the glass edge has a smooth, matte appearance. To achieve a crystal-clear, transparent polish, the machine automatically switches to a final set of tools: felt or specialized polymer wheels. These wheels are used with a continuously flowing slurry of cerium oxide, a fine mineral compound that acts as the ultimate polishing agent for glass. The high-speed friction and chemical action of the cerium oxide bring the edge to a brilliant, flawless polish. Our guide to cnc glass polishing techniques explores this critical final step.

What About Decorative and Artistic Processes?

For decorative and artistic work, a CNC machine uses either a fine, V-shaped diamond tool for physical engraving or a high-pressure abrasive jet (waterjet) or laser for surface etching. The CNC system's ability to precisely control the tool's path allows it to create incredibly intricate, detailed, and perfectly repeatable artistic designs that would be impossible to achieve by hand.

How a CNC Router for Engraving Works

A CNC router equipped with a V-shaped or ball-nosed diamond bit physically carves a groove into the glass surface. By precisely controlling the depth (Z-axis) of the cut, the machine can create stunning 3D relief carvings and intricate line art. Our cnc router for glass engraving guide and our review of the best cnc glass engraving machines are great resources for this.

CNC Engraving vs. CNC Etching

It's important to understand the cnc glass engraving vs cnc glass etching distinction. Engraving is a physical cutting process. Etching is a surface abrasion process, often done with a sandblasting effect or a laser, that creates a frosted appearance without significant depth.

We recently installed a multi-functional CNC working center at a custom glass studio in the Dhaka region that specializes in decorative architectural glass. Their star artisan was a master of manual engraving, but his most complex designs could take him a full week to complete by hand. With the new CNC machine, he can now design an even more intricate pattern on the computer in a single day, and the machine will flawlessly replicate it on ten large panels overnight while he is at home. The technology hasn't replaced his artistry; it has amplified it, turning his vision into a scalable, high-volume reality."

The Next Evolution: How Automation and AI are Making CNC Even Smarter

The future of cnc automation glass processing is about integration and intelligence. The next evolution involves connecting individual CNC machines with robotic systems for automated loading and unloading, enabling 24/7 "lights-out" production. Furthermore, the integration of AI and machine learning is creating "smart factories" where machines can predict their own maintenance needs, optimize their own cutting paths, and work together in a seamless, data-driven ecosystem. [Cite a study from a leading manufacturing technology journal on the productivity gains, often exceeding 200%, achieved through fully integrated, robotic-tended CNC production lines]. [Cite an expert quote from a factory automation specialist on how predictive maintenance, driven by AI analysis of IoT sensor data, can reduce unscheduled machine downtime by over 70%]. The routine maintenance tips for cnc glass machinery of today will become the automated predictive alerts of tomorrow.

Conclusion

A CNC glass machine is far more than just a piece of automated equipment. It is the perfect fusion of a master artisan's skill and the absolute, unyielding precision of a supercomputer. It works by translating the limitless creativity of a digital design into a perfectly executed physical reality through a sophisticated and seamless dance of software, mechanics, and specialized tooling.

Understanding how CNC glass machines work is to understand the very heart of the modern glass fabrication industry. It is a world where human artistry guides the process, but digital precision guarantees the result. This technology has not replaced the need for skilled professionals; it has elevated them, freeing them from the constraints of manual labor and empowering them to produce work of a complexity, consistency, and quality that was once the stuff of dreams.