How 3D Glass Engraving Machines Work Explained

The process of how 3D glass engraving machines work is a remarkable fusion of advanced optics, software, and laser technology. These machines create intricate, three-dimensional images that appear to float inside a solid block of glass or crystal. Unlike traditional methods that mark the surface, this technique, known as sub-surface laser engraving, creates its effect entirely within the material. This guide provides a definitive and clear explanation of this captivating process. It details the science, the components, and the step-by-step workflow. It reveals how a focused beam of light can become a microscopic chisel to build complex art from the inside out.

What is the Fundamental Principle of 3D Glass Engraving?

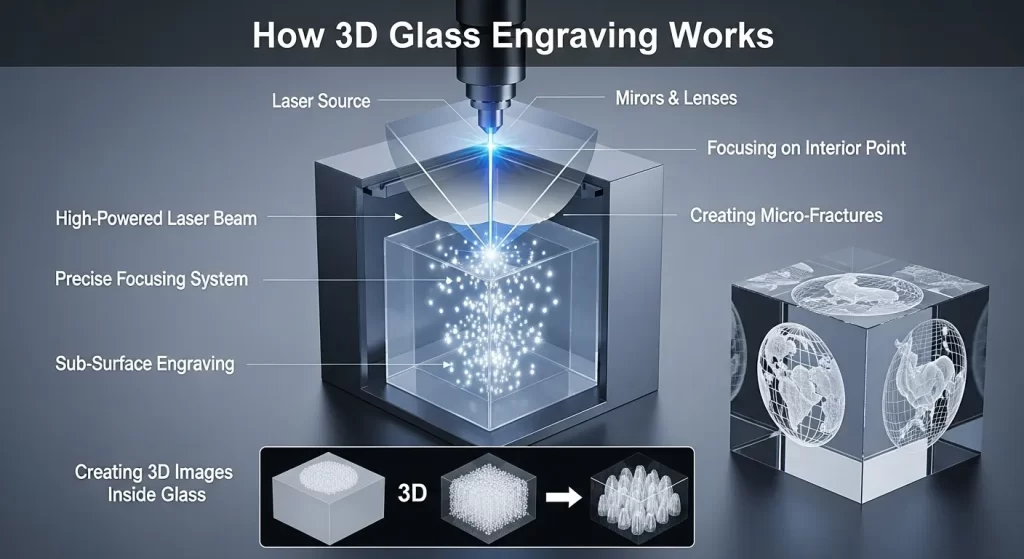

The fundamental principle of 3D glass engraving is the use of a highly focused laser beam to create a series of microscopic fractures, or points, at precise coordinates inside a block of transparent material. The laser is calibrated to pass harmlessly through the surface of the glass. It only delivers enough energy to create a mark at its exact focal point. By plotting and creating millions of these individual points, the machine can construct a complete and detailed three-dimensional image within the glass.

How Does it Differ from Surface Engraving?

This method differs from surface engraving in its location and its method. Surface engraving, whether by laser or a CNC tool, physically alters the exterior of the glass. The difference between glass engraving and etching is a matter of how that surface is altered. 3D sub-surface engraving, by contrast, leaves the outer surfaces of the glass block completely smooth and untouched. The entire design is contained within the volume of the material. This creates a unique and magical effect that surface marking cannot replicate.

What is Sub-Surface Laser Engraving (SSLE)?

Sub-surface laser engraving (SSLE) is the technical term for this process. It is a non-contact, thermal process. It leverages the optical properties of a transparent medium and the precise energy delivery of a laser. The laser is pulsed at a very high frequency. Each pulse creates a single, tiny point of fracture inside the glass. The machine's control system moves the focal point of the laser with incredible speed and accuracy. It plots out the entire image, one point at a time.

Why is a Specialized Laser Required?

A specialized laser is required because the process depends on a phenomenon called non-linear absorption. A standard CO2 laser, often used for surface marking, would simply heat up the surface of the glass. A 3D engraving laser, typically a diode-pumped solid-state (DPSS) laser, uses a specific wavelength of light that is not readily absorbed by the glass. This allows the beam to pass through the surface without effect. However, at the incredibly high energy density of the laser's focal point, the glass is forced to absorb the energy. This creates the desired micro-fracture. The global market for DPSS lasers is significant, driven by their applications in precision manufacturing.

How Does a 3D Glass Engraving Machine Work Step-by-Step?

The process of how 3D glass engraving machines work can be broken down into a clear, sequential workflow. This journey begins with a digital 3D model. It is then converted into a cloud of points. Finally, it is physically rendered inside the glass block by the laser. Each step is a combination of sophisticated software and precision hardware.

Step 1: How is a 3D Model Prepared?

The process begins with a digital 3D model. This can be created using 3D modeling software, captured with a 3D scanner, or converted from a 2D photograph using specialized software. This model is a complete, three-dimensional digital representation of the final object to be engraved. The quality and detail of this initial model are critical. They will directly determine the quality and detail of the final engraved product. A wide array of top glass engraving software tools are used for this stage.

Step 2: What is the Role of the Point Cloud Data?

Once the 3D model is finalized, the machine's control software converts it into a "point cloud." A point cloud is a massive set of Cartesian coordinates (X, Y, Z). Each coordinate represents a single point in space where the laser will create a micro-fracture. A complex model may consist of hundreds of thousands or even millions of individual points. The software also optimizes the order in which these points will be engraved. This is done to maximize speed and minimize internal stresses within the glass.

Step 3: How Does the Laser Focus Inside the Glass?

The laser beam is directed through a series of high-speed mirrors and a final focusing lens. The mirrors, known as galvanometers, can pivot with incredible speed and precision. They are responsible for directing the laser beam in the X and Y directions. The focusing lens moves up and down to control the Z-axis, or the depth of the focal point. By precisely coordinating the movement of the mirrors and the lens, the machine can place the laser's focal point at any of the coordinates within the point cloud.

Step 4: What Creates the Individual Engraved Point?

When the focal point is positioned at a target coordinate, the machine fires a single, high-energy laser pulse. This pulse lasts for only a few nanoseconds. The energy at the focal point is so intense that it overcomes the transparency of the glass. It causes a tiny, localized plasma bubble to form and immediately collapse. This event creates a permanent micro-fracture that is typically less than 100 micrometers in diameter. This tiny, fractured point appears as a small white dot. It is the fundamental building block of the 3D image.

Step 5: How is the Full 3D Image Constructed?

The full 3D image is constructed by repeating Step 4 for every single point in the point cloud. The machine moves the focal point to the next coordinate and fires another laser pulse. It does this at an incredible speed, often creating thousands of points per second. By accurately placing millions of these tiny white dots in a three-dimensional arrangement, the machine effectively "builds" the final image inside the glass, point by point. The density and arrangement of these points create the illusion of solid shapes, surfaces, and gradients.

What Are the Core Components of a 3D Engraving Machine?

A 3D glass engraving machine is a system of highly specialized, interconnected components. Each part plays a critical role in the precise delivery of laser energy. The quality and integration of these components are what define a professional-grade machine. Understanding these parts is key to understanding how the technology achieves its remarkable results.

What Defines the Laser Source and its Wavelength?

The laser source is the heart of the machine. It is typically a diode-pumped solid-state (DPSS) laser. Common types include Nd:YAG or Nd:YVO4 lasers. These lasers produce a beam with a specific wavelength, often in the green (532 nm) or infrared (1064 nm) spectrum. This wavelength is chosen because it is not absorbed by the glass, allowing the beam to pass through the surface cleanly. The laser's power and its ability to produce very short, stable pulses are critical for creating clean, consistent points.

How Do the High-Speed Galvanometer Mirrors Work?

The high-speed galvanometer mirrors, or "galvos," are responsible for steering the laser beam. This system consists of two small, highly reflective mirrors. Each is mounted on a tiny, high-speed motor. One mirror controls the X-axis deflection, and the other controls the Y-axis. By applying precise electrical signals to these motors, the control system can pivot the mirrors with incredible speed and accuracy. This allows the laser beam to be directed to any X-Y coordinate in a fraction of a millisecond.

What is the Function of the Focusing Lens System?

The focusing lens system is the final optical component in the beam's path. It is a high-quality, multi-element lens. Its function is to take the collimated laser beam and converge it to an extremely small, high-energy focal point. The lens is mounted on a motorized stage that can move it up and down. This movement controls the Z-position of the focal point inside the glass. The quality of this lens is critical. It determines the size of the engraved point and the overall resolution of the image.

Why is a High-Quality Optical Glass Block Essential?

The material being engraved is just as important as the machine itself. For sub-surface engraving, a block of high-quality, optically clear crystal or glass is required. The material must be free of any internal imperfections, such as bubbles, striae, or stress lines. These imperfections could interfere with the laser beam. They could cause it to scatter or be absorbed in the wrong place. This would ruin the final engraving. K9 optical crystal is a common choice. It is known for its exceptional clarity and flawless internal structure.

What is the Science Behind the Laser-Glass Interaction?

The science behind the laser-glass interaction is a fascinating area of physics. It relies on a principle that allows a normally transparent material to absorb a massive amount of energy in a very small space and time. This controlled creation of a mark inside a solid object is one of the key engraving and etching innovations of recent decades.

What is Non-Linear Absorption?

Non-linear absorption is the key physical principle at play. Under normal conditions, the glass is transparent to the laser's wavelength. The energy passes right through. However, the laser pulse is so short and the energy at the focal point is so concentrated that the normal rules of physics are overwhelmed. The intensity of the light is so high that the material is forced to absorb the energy through a process called multi-photon absorption. This absorption only happens at the focal point, where the energy density is above a critical threshold.

How is a Micro-Fracture Created Without Damaging the Surface?

A micro-fracture is created without damaging the surface because the laser's energy is only absorbed at the focal point inside the glass. The laser beam travels through the surface and the bulk of the glass at an energy level below the absorption threshold. Therefore, it has no effect. Only at the tiny focal point does the energy density become high enough to trigger the non-linear absorption. This creates a tiny plasma event and a resulting fracture. The surface remains completely untouched.

Why Does the Point Appear White or Frosted?

The engraved point appears white or frosted because it is a small, fractured area. The micro-fracture is not an empty space. It is a region of damaged glass with a complex, shattered internal structure. This fractured surface is no longer perfectly transparent. It reflects and scatters light in all directions. Our eyes perceive this scattered light as a bright, white, or frosted point. The final 3D image is an illusion created by the collective scattering of light from millions of these individual points.

How Does This Technology Compare to Other Engraving Methods?

The technology of sub-surface laser engraving is unique. It produces a result that cannot be replicated by any other method. Its capabilities are distinct from both traditional hand engraving and modern CNC rotary engraving. Understanding these differences is key to appreciating its special place in the world of decorative glass.

What is the Key Difference Compared to CNC Rotary Engraving?

The key difference is location. As the guide on laser engraving vs CNC engraving for glass explains, CNC rotary engraving is a surface process. It uses a physical tool to carve a groove into the outside of the glass. Sub-surface laser engraving works entirely inside the glass. A CNC engraving has a brilliant, sparkling V-groove. A 3D laser engraving has a soft, frosted appearance and is contained within the glass.

How Does it Differ from Traditional Hand Engraving?

It differs from traditional hand engraving in every aspect: method, location, and style. Hand engraving is a highly skilled craft. It uses small, handheld tools to carve intricate designs on the surface of the glass. It is a slow, artistic process valued for its human touch. Sub-surface laser engraving is a high-technology, automated process. It is valued for its unique 3D effect and its perfect, computer-generated precision. Both are forms of engraved glass, but they represent very different approaches to the art form.

Why is Sub-Surface Engraving a Unique Art Form?

Sub-surface engraving is a unique art form because it uses volume, not just surface, as its canvas. The ability to place points anywhere within a three-dimensional space allows for the creation of sculptures made of light and texture. These sculptures are permanently captured within a block of pristine crystal. This combination of technology and artistry has led to a new genre of decorative objects. These range from personal mementos to large-scale architectural installations.

What Are the Main Applications of 3D Glass Engraving?

The main applications of 3D glass engraving are found in markets that value personalization, novelty, and high-perceived value. The unique "floating image" effect has made it incredibly popular for corporate awards, personalized gifts, and decorative art. The technology has created entirely new product categories. The breadth of these is explored in our guide to 3D glass art machine applications.

How is it Used for Personalized Photo Crystals?

The most popular consumer application is the creation of personalized photo crystals. A customer provides a standard 2D photograph. Specialized software is used to convert this 2D image into a 3D model. This model is then engraved inside a crystal block. This creates a unique and lasting 3D portrait. This is a very popular product for commemorating special occasions like weddings, anniversaries, and graduations. The market for personalized gifts has grown substantially with this technology.

What is its Role in Corporate Awards and Trophies?

In the corporate world, 3D laser engraving is used to create stunning and modern awards. A company's logo, a product image, or an architectural rendering can be engraved in 3D inside a crystal block. This creates a sophisticated and high-tech award that stands out from traditional surface-engraved plaques. This is a premium segment of the market for glass engraving for decor and branding.

How is it Applied in Scientific and Medical Visualization?

A fascinating niche application is in scientific and medical visualization. Researchers and doctors can take complex 3D data from sources like MRI scans, CT scans, or molecular modeling software. They can then engrave this data in 3D inside a crystal block. This creates a permanent, physical model of a protein molecule, a human organ, or a complex engineering part. These models are used for education, research, and presentation.

What Are Some Architectural and Artistic Applications?

In architecture and art, the technology is being used on a larger scale. Artists are creating complex abstract sculptures inside large glass blocks. Architects are using it to create detailed 3D models of buildings. It is also being used to create unique decorative elements for high-end interiors. These can include partition walls or decorative panels with intricate internal patterns. Some of these creative uses are highlighted in the guide on glass engraving ideas for architecture.

What Are the Key Considerations for Quality and Maintenance?

Achieving high-quality results and ensuring the machine's longevity require attention to detail. The quality of the final product is influenced by both software settings and the quality of the raw material. The machine itself, being a piece of high-precision optical equipment, requires a clean environment and regular maintenance.

How Does Point Density Affect the Final Image?

The point density, which is the number of engraved dots per cubic millimeter, has a major impact on the final look. A lower point density will result in a more transparent, ethereal-looking image. A higher point density will create a more solid, opaque, and brighter image. The operator must choose the right density to achieve the desired artistic effect. This is a key setting in the control software.

Why is the Quality of the Glass Block So Important?

The quality of the glass block is paramount. As mentioned earlier, any internal flaws in the glass will interfere with the laser. This will ruin the engraving. Sourcing high-quality, optically perfect K9 crystal or its equivalent is essential for professional results. Any cost savings from using a lower-grade material will be lost through rejected parts.

What Are the Essential Maintenance Procedures?

The essential maintenance procedures for a 3D laser engraver are focused on keeping the optics clean and the system cool.

- Optics Cleaning: The laser's focusing lens and the galvanometer mirrors must be kept perfectly clean. Any dust or smudges can absorb laser energy and damage the delicate optical coatings.

- Cooling System: The laser source generates a significant amount of heat and requires a dedicated cooling system, often a water chiller. This system's fluid levels and filters must be checked regularly.

- General Cleaning: The machine should be kept in a clean, dust-free environment to protect its sensitive components. These procedures are detailed in our guide on the maintenance of glass engraving machines.

Conclusion

The process of how 3D glass engraving machines work is a clear example of technology creating a new art form. By harnessing the power of a precisely focused laser, these machines are able to venture inside a solid block of glass. They can build intricate, detailed sculptures from millions of tiny points of light. This technique of sub-surface laser engraving, from its scientific principles to its diverse applications, has redefined what is possible in decorative glass. It is a technology that trades the surface brilliance of traditional engraving for the captivating, magical effect of an image contained and preserved forever within the glass itself.