Glass Shape Beveling vs Straight Beveling: The Definitive Guide

The glass shape beveling vs straight beveling comparison is a fundamental topic that defines the capabilities and specialization of a glass fabrication workshop. While both processes create a beautiful, decorative angled edge on glass, they are achieved through entirely different technologies and are suited for vastly different applications. Straight beveling is a high-speed, linear process designed for mass production. Shape beveling is a flexible, programmable process designed for custom, non-linear designs.1 This guide provides a definitive explanation of these two critical technologies. It covers their mechanics, applications, and the strategic reasons for choosing one over the other.

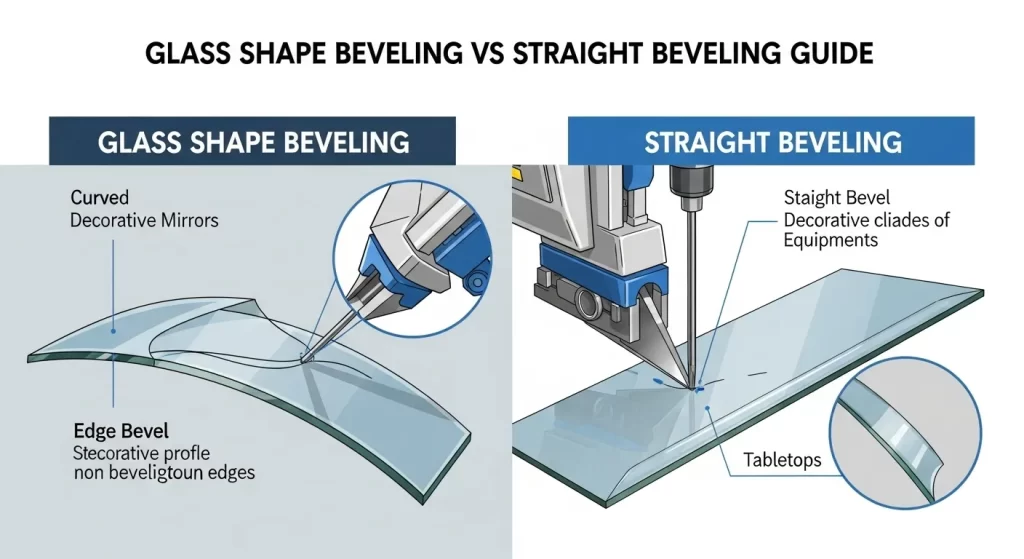

What is the Core Difference Between Shape and Straight Beveling?

The core difference between glass shape beveling and straight beveling lies in their operational method and geometric capability. Straight beveling uses a linear, assembly-line process to rapidly create bevels on the straight edges of rectangular glass.2 Shape beveling uses a versatile, computer-controlled (CNC) process to create bevels on custom shapes, curves, and circles.3

Essentially, the distinction is one of specialization versus flexibility. A straight line beveling machine is a high-speed specialist.4 It is engineered to do one thing—create straight bevels—exceptionally fast and efficiently. A shape beveling machine is a flexible artisan. It can create a bevel on virtually any contour, offering limitless design freedom, but at a slower pace. This fundamental operational difference is the most important takeaway in the glass shape beveling vs straight beveling debate.

What is Straight Beveling in Detail?

Straight beveling is an automated, high-volume manufacturing process. It is designed specifically to produce beveled edges on the straight sides of square and rectangular glass sheets. It is the technology behind the vast majority of beveled mirrors and rectangular glass tabletops produced worldwide. Its design is a model of industrial efficiency, optimized for speed and consistency.

How Does a Straight Line Beveling Machine Work?

A straight line beveling machine works by passing a sheet of glass through a long, linear sequence of grinding and polishing wheels. The glass is held securely by a precision conveyor system. It moves past a bank of fixed-position spindles, each holding a different abrasive wheel. Each wheel performs one specific step of the beveling process in order. This assembly-line approach is the key to its high speed. A complete look at this machine is available in our straight line beveling machine overview.

What Are the Primary Applications of Straight Beveling?

The primary applications of straight beveling are in high-volume production environments. It is the go-to technology for manufacturers of:

- Standard-Sized Mirrors: The vast majority of rectangular bathroom and decorative mirrors are beveled using this method.

- Rectangular Glass Tabletops: For coffee tables, dining tables, and desks.5

- Insulated Glass Units (IGUs): For windows and doors that feature a decorative beveled edge.

- Shelving: For high-end glass shelving systems.The efficiency of the process makes it ideal for any product that requires thousands of identical, straight beveled edges.

What Are the Advantages and Limitations of This Method?

The advantages and limitations of straight beveling are clear and distinct.

- Advantages: The primary advantage is speed. A straight line machine can process linear meters of glass far faster than any other method. This leads to a lower cost per piece in a high-volume setting. It also produces an exceptionally consistent and high-quality finish.

- Limitations: The only limitation is its complete lack of flexibility. It can only process straight lines. It cannot create a bevel on a circle, an oval, an arch, or any piece with a curved edge.

What is Shape Beveling in Detail?

Shape beveling is a versatile, computer-controlled process for creating a beveled edge on non-rectangular or custom-shaped glass.6 It uses a CNC (Computer Numerical Control) machine. This machine can be programmed to follow any contour, from a simple circle to a complex, free-form design. This technology is the key to unlocking creative freedom in decorative glass fabrication.

How Does a Shape (CNC) Beveling Machine Work?

A shape beveling machine works by moving a tool around a stationary piece of glass. The glass sheet is held firmly in place on a flat table using vacuum pods. A multi-axis, computer-controlled tool head, which holds the various grinding and polishing wheels, then travels around the perimeter of the glass. The machine follows a precise path from a digital design file. This allows it to maintain a perfect angle and consistent width on any curve. This process is a key part of how glass beveling machines work in a custom environment.

What Are the Primary Applications of Shape Beveling?

The primary applications of shape beveling are in the custom and high-end decorative glass markets. It is the essential technology for creating:

- Circular and Oval Mirrors: A classic design element that is impossible to create on a straight line machine.

- Custom-Shaped Tabletops: For uniquely designed coffee tables, dining tables, and reception desks.

- Architectural Glass: For arched windows, curved partitions, and other non-linear design elements.

- Artistic and Decorative Pieces: For any design that requires a beveled edge on a free-form shape.The market for custom architectural glass is a significant driver of this technology.

What Are the Advantages and Limitations of This Method?

The advantages and limitations of shape beveling are the inverse of the straight line process.

- Advantages: The primary advantage is ultimate flexibility. It can create a perfect bevel on virtually any shape a designer can imagine. This opens up limitless creative possibilities. It is the foundation of a custom fabrication business.

- Limitations: The process is significantly slower than straight line beveling. The setup time is longer, and the feed rates are generally lower. The initial capital investment in a CNC shape beveler is also typically higher than for a straight line machine.

Head-to-Head Comparison: Speed vs. Flexibility

The glass shape beveling vs straight beveling choice is a strategic one. It is a decision between investing in speed for production or flexibility for custom work. This table provides a clear, at-a-glance comparison of the two technologies.

| Feature | Straight Beveling | Shape Beveling (CNC) |

| Machine Type | Straight-Line Beveling Machine | CNC Glass Working Center |

| Operation | The glass moves, the tools are stationary. | The glass is stationary, the tools move. |

| Geometric Capability | Straight lines only. | Any shape (straight, curved, custom). |

| Primary Advantage | High speed and efficiency. | Ultimate design freedom and versatility. |

| Best Application | High-volume production of rectangles. | Low-volume, high-value custom work. |

| Setup Time | Very low. | Higher (Requires programming). |

| Cost Per Piece | Lower (in high volume). | Higher. |

How Do the Underlying Technologies Differ?

While the end goal of a brilliant, angled edge is the same, the underlying technologies used to achieve it are fundamentally different. The differences in their mechanical structure, control systems, and material handling define their unique capabilities. A deep understanding of these technologies is a key part of glass beveling and edging mastery.

What is the Mechanical Difference in Operation?

The mechanical difference is profound. A straight line machine is a linear, sequential system. It is like a car wash for glass edges. Each station performs one task in a fixed order. A shape beveling machine is a dynamic, multi-axis robotic system.8 Its tool head can move in the X, Y, and Z directions simultaneously. Advanced 5-axis machines can also tilt the tool head.9 This allows for even more complex operations. This mechanical freedom is what enables it to follow any path.

How Does the Control System Vary?

The control system for each machine is tailored to its function. A straight line machine typically uses a PLC (Programmable Logic Controller).10 This is a robust industrial controller designed for repetitive, sequential tasks.11 A shape beveling machine uses a CNC (Computer Numerical Control) system.12 This is a far more sophisticated computer. It can interpret complex G-code programs and calculate the millions of individual motor movements needed to follow a smooth, curved path.

How is Material Handling and Clamping Different?

The material handling methods are completely different. A straight line machine uses a dynamic clamping system. The glass is continuously moved and held by synchronized conveyor tracks. A shape beveling machine uses a static clamping system. The glass is held immobile on a flat table by a series of powerful vacuum pods. This static holding is essential for the tool to be able to trace an accurate path around its perimeter.

When Should a Workshop Choose Straight Beveling?

A workshop should choose to invest in a straight line beveling machine when its business is centered on the high-volume production of standardized, rectangular products.13 If the majority of a workshop's revenue comes from selling mirrors, shelves, or simple tabletops, then a straight line machine is the most efficient and profitable tool for the job. Its speed and consistency will provide a significant competitive advantage in the production market. The decision on how to choose the best glass edger or beveler is primarily driven by this analysis of product mix.

When is Shape Beveling the Essential Choice?

Shape beveling is the essential choice for any workshop that defines itself as a custom fabricator. If a business caters to architects, interior designers, and clients who require unique, one-of-a-kind pieces, then the flexibility of a CNC shape beveler is non-negotiable. The ability to create a perfect bevel on an oval mirror or a curved reception desk is what separates a custom shop from a mass producer. It is the key to entering the high-margin market for bespoke architectural and decorative glass. The growth in this sector is a major trend. [Cite Expert Quote/Data Here on the custom design market].

Can One Machine Do Both?

Yes, a sophisticated 5-axis CNC shape beveling machine can be programmed to produce straight line bevels. It can follow a straight path just as easily as it can follow a curved one. This makes it an incredibly versatile piece of equipment. However, it will never be as fast or efficient at producing straight bevels as a dedicated straight line machine. For a custom shop that occasionally needs to do a few straight bevels, the CNC machine is a perfect all-in-one solution. For a production shop, having separate, specialized machines is the more efficient approach.

How Does the Final Bevel Compare?

In terms of the final quality of the bevel itself, both machines can produce a flawless, brilliant finish. When properly set up and maintained, both a straight line machine and a CNC shape beveler will take the glass through the necessary stages of grinding, fining, and polishing. The final appearance of the beveled glass will be identical. The difference is not in the quality of the final product, but in the geometry of the product it can be applied to and the speed at which it can be produced. The path to a perfect finish is detailed in our guide on polishing glass edges like a pro.

Conclusion

The glass shape beveling vs straight beveling decision is a clear strategic choice between industrial speed and creative artistry. One is not inherently better than the other; they are simply different tools for different business models. The straight line beveling machine is the engine of mass production.14 It delivers perfect, consistent results at incredible speeds for the rectangular products that form the backbone of the industry. The shape beveling machine is the tool of the artisan and the custom fabricator. It provides the freedom to create, to follow any curve, and to bring the most ambitious design visions to life. The best choice for any workshop is the one that best empowers its unique path to success.