A Glass Processing Machine Overview Explained

This glass processing machine overview provides a professional, high-level guide to the essential equipment that forms the backbone of the modern glass fabrication industry. From the initial cut on a raw sheet to the final brilliant polish, each step in the production workflow is performed by a specialized machine. Understanding the role and function of each piece of equipment is fundamental for anyone involved in the glass industry. This definitive guide explains the entire production sequence. It details the purpose and technology of each key machine, from cutting and grinding to drilling and finishing.

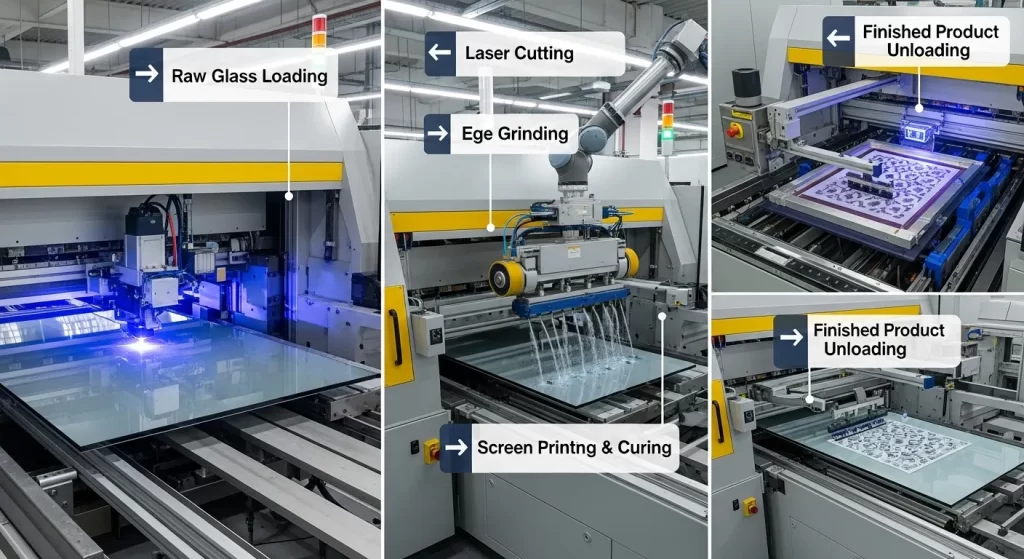

What is the Typical Glass Processing Workflow?

The typical glass processing workflow is a sequential, value-adding process that transforms a large, raw sheet of glass into a finished, ready-to-install product. The glass moves through a series of specialized stations, each performing a specific task. A well-planned workflow is the key to efficiency, quality, and profitability in a modern fabrication facility.

The standard workflow follows a logical progression:

- Cutting: The raw sheet is cut into the required size and shape.

- Grinding/Edging: The sharp, raw edges are shaped for safety and to prepare for polishing.

- Drilling/Milling: Any necessary holes or internal cutouts are created.

- Washing: The glass is thoroughly cleaned to remove all contaminants.

- Finishing: This can include tempering for safety, printing for decoration, or other value-adding processes.

This linear flow ensures that each step builds upon the last, culminating in a high-quality final product.

What is the Role of Glass Cutting Machines?

Glass cutting machines are the first and most critical step in the fabrication process. They are responsible for accurately and efficiently cutting large stock sheets of glass into the specific sizes and shapes required for a job. The precision of the initial cut affects every subsequent process. Modern cutting is an automated, computer-controlled process.

How Do CNC Mechanical Cutting Tables Work?

CNC mechanical cutting tables are the workhorses of the industry. They operate on a "score and break" principle. A computer-controlled cutting head with a small tungsten carbide wheel travels across the glass, creating a precise score line. An integrated breakout system then applies mechanical force to snap the glass cleanly along this line. These machines are known for their incredible speed and efficiency, especially for cutting rectangular shapes. A look at the best glass cutting machine CNC models shows how these systems are optimized for high-volume production.

What is the Role of Laser Cutting Technology?

Laser cutting technology offers a different approach. It is a non-contact, thermal process that uses a focused laser beam to create a controlled fracture in the glass. The primary advantage of a laser is its ability to cut extremely intricate and complex shapes with unparalleled precision. It also produces a smooth, fire-polished edge that often eliminates the need for secondary finishing. The glass cutting laser vs traditional cutting debate often centers on a trade-off between the raw speed of mechanical cutting and the precision and edge quality of the laser.

What Are Glass Grinding and Polishing Machines?

Glass grinding and polishing machines are responsible for finishing the edge of the glass after it has been cut. A raw, cut edge is dangerously sharp and structurally weak. These machines transform it into a safe, durable, and aesthetically pleasing finish. This is a multi-stage process that is essential for any product with exposed edges.

How Does a Basic Glass Edge Grinder Function?

A basic glass edge grinder, often a benchtop model, is used for shaping and safety seaming. As detailed in our guide on how to use a glass edge grinder properly, this machine uses a rotating diamond-abrasive head. The operator manually guides the glass against the head to smooth the edge. These are essential tools for stained glass artists and for basic safety finishing in smaller workshops.

What Defines an Industrial Glass Polishing Machine?

An industrial glass polishing machine is a large, automated system designed for high-volume production. These machines, detailed in our industrial glass polishing machine guide, use a long series of spindles. Each spindle holds a progressively finer grinding or polishing wheel. The glass is fed through the machine on a conveyor. It emerges at the other end with a perfectly ground, fined, and polished edge. These machines are essential for producing the flawless, brilliant edges required for frameless shower doors and glass furniture.

What Are CNC Drilling and Milling Machines?

CNC drilling and milling machines are the tools that create the necessary openings and internal shapes in a glass sheet. This capability is essential for mounting hardware, such as hinges and handles, or for creating complex architectural features. This technology uses computer control and specialized diamond tools to perform these intricate operations with high precision.

What is a Multi-Functional CNC Glass Working Center?

A multi-functional CNC glass working center is the most versatile machine in a custom fabrication shop. This single machine can perform a wide range of tasks. It can drill holes of various sizes. It can also use a milling tool to create non-circular shapes like rectangular cutouts and notches. The details of this technology are covered in our guide to the CNC drilling and milling machine for glass. This versatility makes it the ideal solution for low-volume, high-customization work.

What is a Specialized Vertical Glass Drilling Machine?

A specialized vertical glass drilling machine is a production powerhouse. It is designed for one task: drilling holes at very high speed. As the vertical glass drilling machine explained guide details, this machine holds the glass in an upright position. It often uses two opposing drill heads that drill from both sides simultaneously. This "counter-drilling" technique is extremely fast and produces a very high-quality, chip-free hole. It is the preferred machine for high-volume producers of shower doors and railings. The many automatic glass drilling machine benefits are most evident in this type of specialized equipment.

What Are the Key Auxiliary and Finishing Machines?

Beyond the primary processes of cutting, grinding, and drilling, a full-service glass fabrication facility relies on a number of key auxiliary machines. These machines perform the final, value-adding steps that prepare the glass for its end use. They are essential for cleaning, safety, and ensuring the long-term performance of the final product.

What is the Purpose of an Industrial Glass Washing Machine?

An industrial glass washing machine is a critical but often overlooked piece of equipment. After the fabrication processes, the glass is covered in coolant, glass powder, and fingerprints. A washing machine uses a series of high-pressure spray nozzles and rotating brushes to thoroughly clean and dry the glass. A perfectly clean, residue-free surface is an absolute requirement before the glass can be tempered, coated, or sealed into an insulated glass unit. The quality of the wash has a direct impact on the quality of these downstream processes.

What is the Role of a Tempering Furnace?

A tempering furnace is a large oven that is used to create safety glass. The fabricated glass is heated to a very high temperature and then rapidly cooled. This process creates high compression in the outer surfaces of the glass and tension in the core. This makes the glass four to five times stronger than standard, annealed glass. It also causes the glass to break into small, relatively harmless pebbles if it is ever broken. Tempering is a mandatory process for many architectural and automotive applications. The global market for safety glass is substantial.

How Do Water Filtration Systems Support the Process?

Water is the lifeblood of a glass fabrication shop. It is used as a coolant for all grinding, drilling, and polishing processes. A high-quality water filtration system is essential for both quality and sustainability. These systems remove the fine glass particles from the water. This allows the water to be recycled and reused in a closed loop. This dramatically reduces a factory's water consumption. It also ensures that the water being used is clean. Clean coolant is essential for achieving a high-quality finish and for extending the life of diamond tools. Water recycling systems can reduce water usage by over 90%.

How Does Automation Integrate These Machines?

The trend in modern glass fabrication is toward full automation and integration. The goal is to create a seamless production line where the glass moves from one process to the next with minimal manual intervention. This "connected workshop" concept is the key to maximizing efficiency and reducing labor costs. This is the future of improving production with automatic glass machines.

What is the Role of Robotic Loading and Handling?

Robotic arms and automated gantry systems are increasingly used for material handling. A robot can automatically load a large stock sheet onto a cutting table. Another robot can pick up a finished part from a CNC machine and place it onto a conveyor. This automation reduces the risk of injury associated with manually handling heavy, sharp glass. It also reduces the risk of breakage. It is a key component of a high-volume, "lights-out" manufacturing environment.

How Does Software Create a Connected Production Line?

Software is the intelligence that connects the individual machines. A central Manufacturing Execution System (MES) or Enterprise Resource Planning (ERP) system can manage the entire production schedule. A job order is entered into the system. The software then automatically sends the correct programs to the cutting machine, the CNC edger, and the drilling machine. Barcodes are often used to track each piece of glass as it moves through the factory. This ensures that the right operations are performed on the right part at the right time. This digital integration is the key to achieving a high level of drilling, cutting, and grinding efficiency.

What Are the Universal Maintenance and Safety Considerations?

Across all of these different machines, two universal principles apply: a commitment to proactive maintenance and an unwavering focus on safety. These are the human elements that ensure the technology performs as intended.

A robust maintenance program is essential for the long-term health of any glass processing machine. The wet and abrasive environment is harsh on mechanical components. A program of regular cleaning, lubrication, and inspection, as detailed in our guide on glass grinding machine maintenance, is crucial. This proactive approach prevents costly breakdowns and preserves the machine's accuracy.

Safety is the top priority in any glass workshop. All operators must be thoroughly trained on the specific hazards of their machine. They must use the correct Personal Protective Equipment (PPE) at all times. A comprehensive overview of these essential protocols is available in our guide on safety tips for glass cutting and grinding. A safe workshop is an efficient and productive workshop.

Conclusion

This glass processing machine overview reveals that a modern fabrication facility is not just a collection of individual tools. It is a highly integrated system of specialized machines. Each machine, from the high-speed CNC cutter to the meticulous industrial polisher, is a master of its specific task. When these machines are connected and managed by intelligent software and skilled personnel, they form a powerful production line. This line is capable of transforming a simple raw material into a vast array of sophisticated, high-value products. Understanding this system is the key to understanding the heart of the modern glass industry.