Glass Laser Engraving Machines: Precision for Maritime and Glass Applications

Maritime components like life rafts, propellers, rudders, and anchors must endure harsh marine environments, while glass elements—such as yacht windows, control panels, or decorative features—require intricate designs and flawless finishes. Glass laser engraving machines, powered by advanced CNC technology, are transforming these industries by enabling precise, customizable engravings on glass and related materials. At BN Machine, we specialize in providing state-of-the-art CNC solutions, including glass laser engraving machines, that empower manufacturers to excel in maritime and glass processing applications. This comprehensive guide explores how these machines enhance the production of glass components for maritime use, highlighting BN Machine’s expertise and innovative technology.

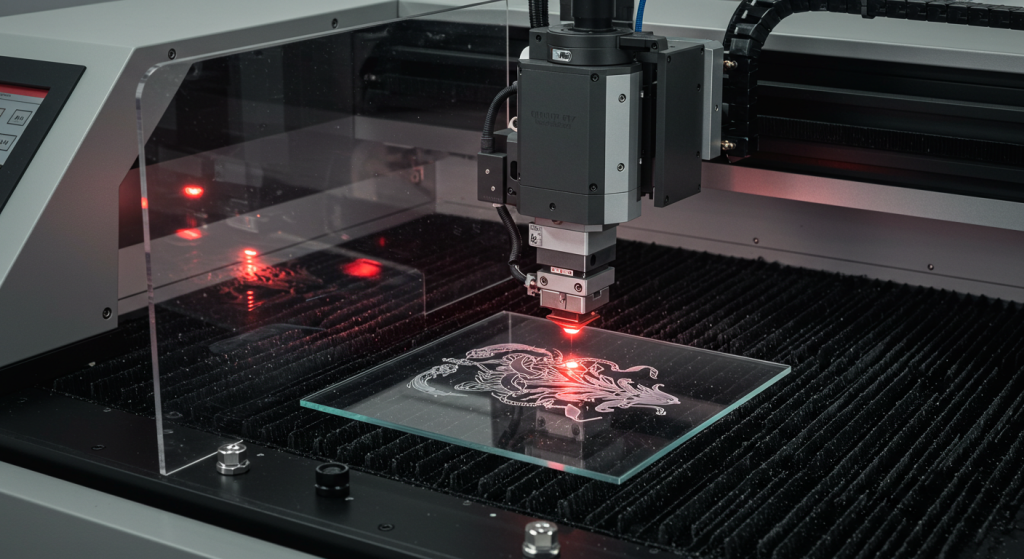

The Capabilities of Glass Laser Engraving Machines

Glass laser engraving machines are specialized CNC systems that use focused laser beams to etch, engrave, or mark designs onto glass and other materials, such as composites, metals, and polymers. These machines offer exceptional precision, achieving resolutions as fine as 0.01 mm, and can create intricate patterns, logos, text, or functional markings without physical contact, reducing the risk of cracking or damaging delicate materials. Unlike traditional engraving methods, laser engraving is fully automated, ensuring consistency and scalability for high-volume production.

In maritime and glass processing contexts, glass laser engraving machines are used for tasks such as:

- Engraving decorative patterns or logos on glass panels for yacht cabins, life raft canopies, or control systems.

- Marking serial numbers, compliance labels, or traceability codes on glass or composite components for propellers, rudders, and anchors.

- Creating functional grooves or textured surfaces on glass for enhanced grip or optical properties.

- Ensuring high-quality, consistent engravings in large-scale production of glass elements for vessels.

These machines integrate with CAD/CAM software, allowing precise translation of digital designs into engraved components. By automating the engraving process, they eliminate human error, minimize material waste, and accelerate production, all while meeting standards like those of the International Maritime Organization (IMO) for maritime components or architectural glass regulations.

BN Machine’s glass laser engraving machines are engineered for precision, versatility, and efficiency, featuring high-power lasers, advanced cooling systems, and Industry 4.0 capabilities like IoT monitoring. Let’s explore how these machines contribute to the manufacturing of glass components for life rafts, propellers, rudders, anchors, and related maritime applications.

Glass Laser Engraving for Propellers

Propellers: Precision in Propulsion Systems

Propellers are critical to a vessel’s propulsion, requiring precise manufacturing to optimize fuel efficiency, reduce vibration, and ensure durability. While propellers are typically made from metals like stainless steel or bronze, glass laser engraving machines play a significant role in related applications, such as engraving glass panels for control systems, testing environments, or decorative elements associated with propeller manufacturing. For example, glass panels with engraved logos or serial numbers may be used in control rooms for propeller monitoring systems or as aesthetic features in luxury yachts.

How Glass Laser Engraving Machines Enhance Propeller Applications

BN Machine’s glass laser engraving machines are equipped with CO2 or fiber lasers, optimized for engraving glass and composite materials with exceptional accuracy. These machines feature automated focusing systems and air-cooling to prevent thermal stress, ensuring clean, precise engravings. The engraving process for propeller-related glass components includes:

- Design Input: Engineers use CAD software to create designs for engravings, such as logos, serial numbers, or functional markings.

- Material Setup: Glass panels are placed on the machine’s worktable, with automated alignment for precise positioning.

- Laser Engraving: The CNC machine directs the laser beam to etch the design, controlling depth and intensity for consistent results.

- Quality Control: Automated inspection systems verify engraving clarity and accuracy, ensuring compliance with design standards.

For propeller manufacturing, BN Machine’s machines support the engraving of glass panels used in control systems or testing fixtures, where markings ensure traceability and compliance. The machines also enable the creation of decorative engravings on glass components, enhancing the aesthetic appeal of luxury maritime interiors.

Benefits of Glass Laser Engraving for Propellers

- Precision: High-resolution engravings ensure clear, accurate markings for traceability and branding.

- Material Integrity: Non-contact laser engraving prevents cracks or damage to delicate glass surfaces.

- Efficiency: Automated engraving reduces production time, supporting rapid delivery of glass components.

- Versatility: BN Machine’s machines handle various glass types and engraving depths, accommodating diverse propeller-related applications.

By leveraging BN Machine’s glass laser engraving machines, manufacturers can produce high-quality glass components that support propeller systems, enhancing both functionality and aesthetics in maritime applications.

Glass Laser Engraving for Rudders

Rudders: Steering with Precision and Elegance

Rudders are essential for vessel navigation, requiring precise manufacturing for hydrodynamic efficiency and structural integrity. While rudders are primarily made from metals or composites, glass laser engraving machines are used in related applications, such as engraving glass panels for rudder control systems or decorative elements in luxury vessels. For example, glass dashboards or control panels in yacht bridges may feature engraved logos, text, or functional markings for enhanced usability and visual appeal.

Glass Laser Engraving in Rudder-Related Applications

BN Machine’s glass laser engraving machines are designed to process tempered glass, laminated glass, and composites with high precision. These machines use adjustable laser power and automated scanning systems to ensure clean, consistent engravings. The engraving process for rudder-related glass components includes:

- Design Integration: A 3D model specifies engraving patterns, such as logos, control labels, or textured surfaces.

- Material Handling: Glass panels are secured on the machine’s worktable, with air-cooling to prevent thermal distortion.

- Laser Engraving: The CNC machine etches the design, controlling laser intensity for shallow or deep engravings as needed.

- Finishing: Automated cleaning ensures residue-free surfaces, enhancing clarity and durability.

BN Machine’s systems support high-speed engraving, enabling the production of complex patterns on thick glass panels used in maritime control systems or decorative rudder assemblies. The non-contact nature of laser engraving ensures no stress is applied to the glass, preserving its structural integrity.

Advantages of Glass Laser Engraving for Rudders

- Aesthetic Excellence: Precise engravings create professional, high-end designs, enhancing luxury vessel interiors.

- Functionality: Clear, durable markings improve usability of control panels, critical for navigation systems.

- Customization: BN Machine’s machines support intricate patterns, enabling bespoke designs for rudder control systems.

- Regulatory Compliance: High-precision engravings ensure components meet maritime and architectural standards.

With BN Machine’s glass laser engraving technology, manufacturers can produce glass components that complement rudder systems, blending functionality with sophistication in maritime applications.

Glass Laser Engraving for Anchors

Anchors: Stability with Aesthetic Appeal

Anchors provide critical stability, requiring robust construction to withstand extreme loads. While anchors are typically metal, glass laser engraving machines are used in related applications, such as engraving glass panels for anchor display cases, testing fixtures, or decorative elements in luxury vessels. For example, glass panels with engraved logos or patterns may be used in onboard design features that incorporate anchor motifs or as protective covers for anchor storage.

Glass Laser Engraving for Anchor-Related Applications

BN Machine’s glass laser engraving machines are optimized for precision and reliability, ensuring flawless engravings on delicate materials like glass. These machines feature programmable laser settings and automated positioning systems for consistent results. The engraving process for anchor-related glass components includes:

- Design Planning: Engineers specify engraving patterns, such as logos, serial numbers, or decorative motifs.

- Material Setup: Glass panels are placed on the machine’s worktable, with automated alignment for accuracy.

- Laser Engraving: The CNC machine etches the design, controlling depth and clarity for optimal visibility.

- Quality Assurance: Automated inspection verifies engraving quality, ensuring functionality and aesthetics.

BN Machine’s systems support the engraving of glass panels for anchor display cases, where intricate designs enhance visual appeal and brand identity. The machines also handle composite materials used in anchor testing fixtures, engraving traceability codes for regulatory compliance.

Benefits of Glass Laser Engraving for Anchors

- Aesthetic Appeal: High-resolution engravings enhance the visual quality of glass components, ideal for luxury maritime applications.

- Traceability: Clear, durable markings ensure compliance with regulatory standards.

- Efficiency: Automated engraving accelerates production, enabling rapid delivery of custom components.

- Durability: Non-contact engraving ensures long-lasting, damage-free surfaces.

BN Machine’s glass laser engraving machines enable manufacturers to produce glass components that support anchor-related applications, combining functionality with elegance.

Glass Laser Engraving for Life Rafts

Life Rafts: Safety with Precision

Life rafts are critical safety equipment, requiring lightweight, durable construction for rapid deployment in emergencies. Glass laser engraving machines are used in related applications, such as engraving glass panels for life raft canopies, protective covers, or storage compartments. For example, glass panels with engraved compliance labels or serial numbers may be used as transparent covers for emergency equipment, ensuring traceability and clarity.

Glass Laser Engraving in Life Raft Production

BN Machine’s glass laser engraving machines are designed to handle tempered glass, laminated glass, and lightweight composites with precision. The engraving process for life raft-related components includes:

- Design Specification: A 3D model details engraving patterns, such as compliance labels, serial numbers, or functional markings.

- Material Preparation: Glass panels are secured on the machine’s worktable, with air-cooling to prevent thermal stress.

- Laser Engraving: The CNC machine etches the design, controlling laser intensity for clear, durable results.

- Traceability: Engraved markings ensure compliance with IMO and SOLAS standards.

BN Machine’s systems feature high-precision lasers, ideal for thin glass used in life raft components, ensuring damage-free engravings without compromising strength.

Advantages of Glass Laser Engraving for Life Rafts

- Safety Compliance: Precise engravings ensure components meet IMO and SOLAS standards, critical for emergency equipment.

- Clarity: Clear, durable markings enhance visibility and usability of glass components.

- Production Speed: Automated engraving accelerates manufacturing, supporting rapid production of safety-critical components.

- Durability: Non-contact engraving ensures secure, long-lasting markings.

By using BN Machine’s glass laser engraving machines, manufacturers can produce reliable, high-quality glass components for life rafts, enhancing maritime safety and performance.

The Advantages of Glass Laser Engraving Machines

Why Choose Glass Laser Engraving?

Glass laser engraving machines offer significant advantages over traditional methods, making them indispensable for maritime and glass processing applications:

- Precision: Resolutions as fine as 0.01 mm ensure clear, accurate engravings for functionality and aesthetics.

- Non-Contact Process: Laser engraving prevents cracks or damage, preserving material integrity.

- Versatility: Machines handle glass, composites, and lightweight metals, accommodating diverse maritime needs.

- Efficiency: Automated engraving minimizes production time and costs.

- Sustainability: Precise engraving reduces material waste, supporting eco-friendly manufacturing.

BN Machine’s Glass Laser Engraving Solutions

BN Machine offers a range of glass laser engraving machines tailored to maritime and glass processing needs, featuring:

- High-Power Lasers: For rapid, accurate engraving on various materials.

- Automated Focusing Systems: For consistent depth and clarity.

- Industry 4.0 Integration: IoT sensors for real-time monitoring and predictive maintenance.

- CAD/CAM Compatibility: For streamlined design-to-production workflows.

Our machines are built for reliability and precision, ensuring consistent performance in high-volume production environments.

Best Practices for Optimizing Glass Laser Engraving Operations

To maximize the benefits of glass laser engraving, manufacturers should adopt the following best practices:

- Regular Maintenance: Calibrate lasers monthly to maintain precision. Clean lenses and cooling systems to prevent debris buildup.

- Operator Training: Train staff on CAD/CAM software, laser operation, and safety protocols to optimize performance and reduce errors.

- Material Selection: Choose tempered or laminated glass for maritime applications to enhance durability and safety.

- Laser Optimization: Adjust laser power and speed based on material thickness to achieve clear, damage-free engravings.

- Quality Control: Implement automated inspection systems to verify engraving quality and detect defects, ensuring compliance with industry standards.

BN Machine supports clients with comprehensive training, technical support, and maintenance services, ensuring seamless CNC operations.

The Future of Manufacturing with Glass Laser Engraving

The maritime and glass processing industries are evolving, driven by trends like automation, sustainability, and digitalization. Glass laser engraving machines are at the forefront of this transformation, enabling manufacturers to:

- Adopt Industry 4.0: IoT-enabled machines provide data analytics for predictive maintenance and process optimization.

- Enhance Sustainability: Precision engraving minimizes material waste and energy consumption, aligning with environmental goals.

- Meet Growing Demand: Automated systems scale production to meet the needs of expanding maritime and architectural markets.

BN Machine is committed to driving this evolution, offering innovative glass laser engraving solutions that empower manufacturers to stay competitive in a dynamic industry.

Conclusion

Glass laser engraving machines are revolutionizing manufacturing for maritime and glass processing applications, delivering the precision, efficiency, and reliability needed to produce high-quality glass components for life rafts, propellers, rudders, anchors, and related systems. These machines ensure every engraving is clear, durable, and aesthetically pleasing, enhancing safety, performance, and visual appeal. At BN Machine, we’re proud to lead the way with our advanced glass laser engraving solutions, designed to meet the diverse needs of manufacturers.

Whether you’re engraving glass panels for a yacht’s control system, marking life raft components for compliance, or creating decorative elements for anchor displays, BN Machine has the expertise and technology to elevate your operations. Visit bnmachine to explore our range of glass laser engraving machines or contact our team for a consultation. Together, we can shape the future of maritime and glass manufacturing with precision and innovation.