A Professional Guide to Glass Grinding Machine Maintenance

A professional glass grinding machine maintenance program is the most critical investment a workshop can make in its own success. These machines, the workhorses of the glass fabrication industry, operate in a harsh environment of abrasive dust and constant moisture. Without a systematic and proactive schedule of care, their precision will degrade, their reliability will falter, and their lifespan will be cut short. This definitive guide provides an expert checklist for a comprehensive maintenance program. It covers the daily, weekly, and monthly tasks necessary to ensure your equipment remains a precise, reliable, and profitable asset for years to come.

What is the Core Philosophy of Glass Grinder Maintenance?

The core philosophy of glass grinder maintenance is a proactive commitment to preventing failures before they happen. This approach shifts the focus from reactive repairs to a structured schedule of inspections, cleaning, and preventative care. It is the understanding that consistent, planned maintenance is far less costly than the sudden, catastrophic failure of a critical production asset. This philosophy is the foundation of a stable and efficient manufacturing environment.

How Does Proactive Maintenance Prevent Failures?

Proactive maintenance prevents failures by addressing small issues before they escalate into major problems. Regular cleaning removes abrasive contaminants that cause wear. Routine lubrication reduces friction on moving parts. Scheduled inspections can identify a wearing belt or a failing bearing long before it breaks. This preventative approach dramatically reduces unscheduled downtime and the high costs associated with emergency repairs and lost production. The impact of unexpected downtime on a business's bottom line is substantial.

What Are the Primary Goals of a Maintenance Program?

The primary goals of a maintenance program are to preserve the machine's core functions:

- Accuracy: To maintain the machine's ability to grind glass to precise dimensions and profiles, ensuring the quality of the final product.

- Reliability: To maximize the machine's uptime, ensuring it is always ready for production when needed.

- Safety: To keep all safety systems, such as guards and emergency stops, in perfect working order to protect operators.

- Longevity: To extend the operational lifespan of the machine, maximizing the return on a significant capital investment.

Who is Responsible for the Maintenance Tasks?

Maintenance is a shared responsibility between the machine operators and dedicated maintenance technicians. Operators are the first line of defense. They are with the machine every day and are responsible for daily cleaning, checks, and monitoring. Technicians are responsible for more in-depth weekly, monthly, and annual tasks that require more specialized tools and knowledge. A successful program requires a strong partnership and clear communication between these two roles.

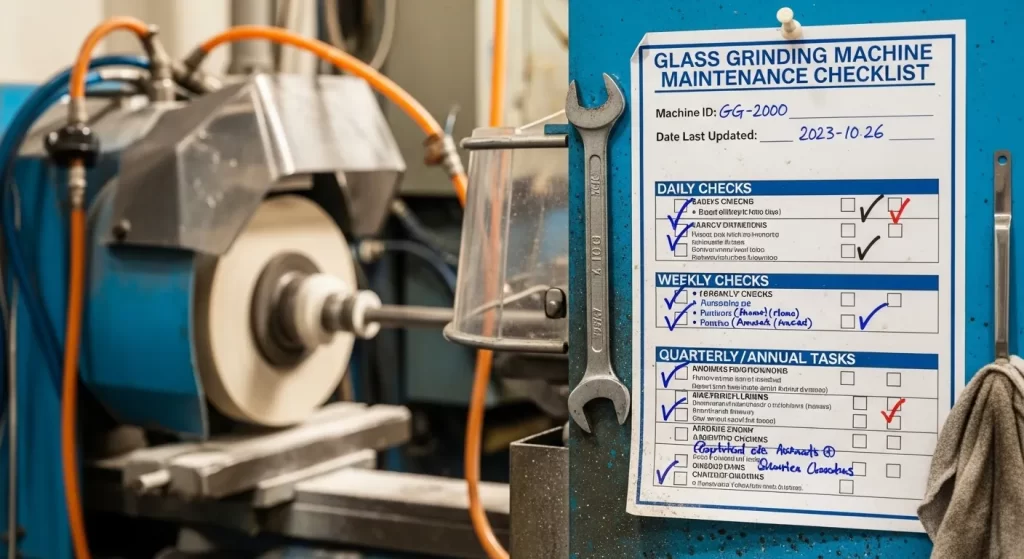

What is the Daily Maintenance Checklist for Operators?

The daily maintenance checklist consists of a series of quick but essential tasks. These should be performed by the operator at the beginning of every shift. This simple routine, which takes only a few minutes, is the most effective way to ensure the machine is safe, clean, and ready to perform at its best.

How to Perform the Daily Machine Cleaning?

A thorough daily cleaning is the most important maintenance task. The operator should remove all glass powder, dried slurry, and glass shards from the machine bed, work surfaces, and the surrounding floor area. A clean machine is a safer machine and a more accurate machine. Abrasive glass dust is the primary enemy of precision components. This cleaning prevents the dust from working its way into sensitive areas like linear guide rails and bearings.

What is the Procedure for Inspecting the Coolant System?

The coolant system is the lifeblood of the grinding process. The operator must check the coolant level in the main reservoir and top it off if necessary. They should turn the system on and visually inspect the nozzles. They must ensure a strong, steady flow of coolant is directed at all the grinding wheels. A clogged nozzle can lead to a wheel running dry. This will instantly damage both the glass and the expensive diamond tool. This is a key part of the process of how to use a glass edge grinder properly.

How to Check the Pneumatic and Electrical Systems?

A quick check of the pneumatic and electrical systems is required. The operator should look at the main air pressure gauge to ensure it is within the recommended range. They must drain the water separator on the main air line. This prevents moisture from entering the machine's pneumatic components, where it can cause corrosion. A visual inspection of all visible electrical cables should be done to check for any signs of damage.

What Visual Inspections of Grinding Tools Are Needed?

The operator should perform a quick visual inspection of the diamond grinding wheels. They should look for any obvious signs of damage, such as large chips or an uneven surface. They should also ensure that the wheels are securely mounted on the spindles. Running a machine with a damaged or loose grinding wheel is a serious safety hazard. It will also produce a very poor-quality finish. This is a core part of how to extend the life of glass grinding tools.

How Do You Verify All Safety Features?

Verifying the safety features is a non-negotiable daily task. The operator should test each emergency stop button to confirm that it immediately halts all machine motion. They should check that all physical guards are in place and secure. For enclosed machines, they must verify that the safety interlocks on the access doors are functioning correctly. The machine should not start if a door is open. A full list of best practices is available in our guide on safety tips for glass cutting and grinding.

What Are the Weekly Maintenance Tasks?

Weekly maintenance tasks are more in-depth. They often require the machine to be powered down and locked out. These tasks focus on the cleaning and inspection of the machine's core motion and fluid systems. They are designed to prevent the gradual degradation of the machine's performance.

How to Clean and Inspect the Motion Systems?

The machine's motion systems, such as the linear guide rails and ball screws, must be kept perfectly clean. Once a week, a technician should wipe down these components with a clean, lint-free cloth. This removes the fine, abrasive slurry that can work its way past the protective seals. After cleaning, the components should be lubricated according to the manufacturer's specifications. This ensures smooth, low-friction movement, which is essential for accuracy.

What is Involved in Cleaning the Coolant Filtration System?

The coolant filtration system requires weekly attention to remain effective. The primary filters, which may be paper cartridges, mesh screens, or a cyclonic separator, must be cleaned or replaced. The main coolant tank should be inspected for a heavy buildup of settled glass sludge. This abrasive sludge can be recirculated if the tank is not cleaned. This will damage the coolant pump and cause scratches on the glass. A clean coolant system is a key factor in improving drilling, cutting, and grinding efficiency.

How Do You Inspect the Machine's Clamping System?

The system that holds the glass in place must be inspected weekly. For a CNC machine, this involves checking the rubber seals on the vacuum pods for any cuts or wear. For a straight-line machine, this involves inspecting the conveyor pads and the top clamping pads for wear or damage. All vacuum and pneumatic hoses should be checked for cracks or loose fittings. A secure clamping system is essential for both safety and quality.

How to Verify the Automatic Tool Changer (ATC)?

For machines equipped with an ATC, a weekly cleaning and functional check is important. The technician should clean the tool gripper mechanism and the individual tool pockets in the carousel. They can then command a manual tool change through the controller. They should observe the entire sequence to ensure it is smooth and precise. Any hesitation or unusual noise could be an early sign of a problem. This is a core component of a modern CNC drilling and milling machine for glass.

What is the Process for Backing Up Machine Data?

Backing up the machine's digital brain is a critical data protection task. A technician should perform a full backup of the CNC controller's memory. This includes all machine parameters, tool offset libraries, and any stored programs. This backup should be saved to an external device, such as a USB drive or a network server. This simple action can save days of reprogramming in the event of a controller failure. The importance of data backup in an automated environment cannot be overstated.

What Are the Monthly and Quarterly Maintenance Procedures?

Monthly and quarterly procedures are more intensive and are typically performed by a skilled maintenance technician. These tasks involve lubrication of hidden components, mechanical adjustments, and deep cleaning of entire systems. They are designed to ensure the machine's long-term health and accuracy.

How is the Centralized Lubrication System Maintained?

Most industrial glass grinders have a centralized automatic lubrication system. This system has a main reservoir for grease or oil. This reservoir must be checked and refilled on a monthly basis. The technician should also inspect the distribution block and the small lubrication lines that run to each bearing and guide block. They must ensure that the lubricant is being properly dispensed at the correct intervals.

What is the Procedure for Inspecting Drive Systems?

The machine's drive systems, which connect the motors to the moving parts, require a monthly inspection. This involves checking the tension of any drive belts. A loose belt can cause a loss of positioning accuracy. The technician should also inspect the belts for any signs of cracking or wear. For direct-drive systems, the couplings that connect the motor shaft to the ball screw should be checked to ensure their locking bolts are tight.

How to Clean and Service the Control Cabinet?

The main electrical control cabinet is the machine's nerve center. It contains the CNC controller, servo drives, and other sensitive electronics. These components generate heat and are cooled by fans with filters. On a monthly basis, these filters must be removed and cleaned or replaced. A clogged filter will cause the cabinet to overheat. This can lead to random electronic faults or permanent damage to the components. The cost of a new filter is trivial compared to the cost of a new servo drive.

How to Perform a Basic Machine Accuracy Test?

On a quarterly basis, a basic machine accuracy test provides a good health check. The technician programs the machine to grind a large, precise square or other geometric shape from a piece of scrap glass. They then use calibrated measuring tools, such as a large caliper or a CMM, to measure the finished part. This test can reveal any developing issues with the machine's positioning accuracy or squareness. This level of precision is critical for the processes used in fields like Precision glass moulding.

What is Involved in a Full Coolant System Flush and Replacement?

A full coolant system flush is a major but necessary quarterly task. The entire coolant reservoir is drained. All the accumulated glass sludge is shoveled out and disposed of according to local regulations. The tank, pumps, and all lines are then thoroughly cleaned and flushed. The system is then refilled with fresh, clean water and the correct concentration of coolant additive. This process removes the fine abrasive particles that can build up over time and degrade the finish quality.

How to Maintain Specific Core Components of the Grinder?

Certain core components of a glass grinding machine require special attention. The spindle, the diamond tools, and the vacuum pump are all high-performance systems. Their specific maintenance needs are critical to the overall performance of the machine.

How Do You Maximize the Life of the Spindle?

Maximizing the life of the high-speed spindle involves a few key practices. A proper warm-up cycle should be run at the start of each day. This allows the spindle's bearings to reach a stable operating temperature before being placed under load. The spindle's internal taper and the tool holders must be kept spotlessly clean. Any debris in this interface can cause runout and damage the spindle. Operators should also be trained to listen for any changes in the sound of the spindle, which can be an early warning of bearing failure.

What is the "Dressing" Process for Diamond Wheels?

"Dressing" is the process of cleaning and re-sharpening a diamond grinding wheel. Over time, the metal bond of the wheel can wear smooth over the diamond particles, a condition known as "glazing." A dressing stick, which is a block of very coarse abrasive material, is carefully pushed against the rotating wheel. This action erodes the glazed bond material. It exposes fresh, sharp diamond particles. Regular dressing restores the wheel's cutting efficiency and is a key part of how to extend the life of glass grinding tools.

What Maintenance is Required for the Vacuum Pump?

The maintenance for the vacuum pump depends on its type. An oil-lubricated pump requires regular oil changes. The frequency depends on the hours of use. A dry-running pump has internal carbon vanes that are a wear item. These must be inspected and replaced periodically. All types of pumps have intake filters that must be cleaned regularly to ensure they are not clogged with dust. A well-maintained pump will provide a stronger, more reliable vacuum.

Conclusion

A comprehensive glass grinding machine maintenance program is the foundation upon which a reliable and profitable glass fabrication business is built. It is a proactive and systematic commitment to preserving the accuracy and performance of a critical asset. By implementing a structured schedule of daily, weekly, and monthly tasks, and by fostering a culture where maintenance is a shared responsibility, a workshop can ensure its equipment operates at peak efficiency. This diligent care is the key to minimizing downtime, maximizing quality, and achieving a superior level of operational excellence.