Glass Engraving Laser Machines: 2025 Guide & Reviews

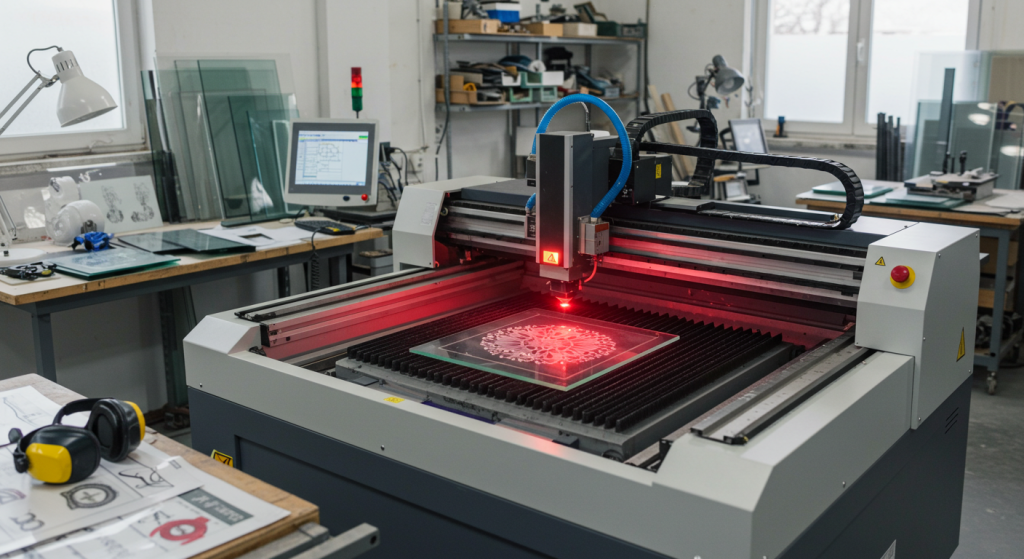

Picture this: you’re at a wedding, holding a wine glass etched with the couple’s initials, or walking past a sleek office with frosted glass panels showcasing a company logo. Those stunning designs? They’re the work of glass engraving laser machines, the unsung heroes turning plain glass into personalized art. In 2025, these machines are more affordable and user-friendly than ever, letting hobbyists craft heartfelt gifts and businesses create high-end decor or branded products. From sleek desktop models to industrial powerhouses like FUJIAN BAINENG’s Glass Laser Etching Machine, there’s a machine for every dream project.

In this guide, we’ll dive into everything you need to know about glass engraving laser machines. We’ll explore how they work, the different types available, their applications, and how they stack up against other methods like sandblasting. Plus, I’ll share tips to choose the right machine and get flawless etches. Whether you’re a beginner or a pro, you’re about to unlock the secrets to creating glass designs that wow. Let’s get started!

What Is a Glass Engraving Laser Machine?

A glass engraving laser machine is a high-tech tool that uses a focused laser beam to etch designs onto glass surfaces, creating frosted, permanent patterns like logos, text, or intricate artwork. Unlike traditional methods, it’s non-contact, meaning the laser doesn’t touch the glass, reducing the risk of cracks on delicate pieces as thin as 0.5mm, as explained by xTool. The magic happens when the laser—usually a CO2 or UV type—vaporizes or fractures the glass surface, leaving a smooth, durable etch with up to 1200 DPI resolution.

These machines typically include a laser source, a gantry to move the beam, and a worktable for flat glass or a rotary attachment for curved items like bottles. You control it all with software like LightBurn, which lets you upload designs and tweak settings. FUJIAN BAINENG’s CNC Glass Engraving Machine takes it up a notch, offering 2D and 3D precision for complex patterns, perfect for professional workflows, per BAINENG. Whether you’re etching a single glass or a batch of mirrors, these machines deliver crisp, professional results with minimal fuss.

Types of Glass Engraving Laser Machines

Choosing the right glass engraving laser machine depends on your projects, budget, and space. Here’s a rundown of the main types available in 2025, each tailored to specific needs:

CO2 Laser Engravers

CO2 lasers are the go-to for glass engraving, using 40W-150W beams to create frosted designs on flat or curved surfaces. Models like the xTool P2 (55W) or Glowforge Pro have workbeds up to 495x279mm, making them perfect for glassware, mirrors, or small panels. They cost $2,000-$5,000 and are a favorite for hobbyists and small businesses, per CNET. For example, you could etch a set of personalized tumblers for a wedding in under an hour.

UV Laser Engravers

UV lasers, like the ComMarker Omni 1 (3W-5W), use low heat to produce ultra-fine etches, ideal for delicate or tempered glass where heat could cause cracks. They’re pricier, ranging from $5,000-$10,000, but shine for high-contrast designs, like intricate text on thin glass ornaments, per Hobby Laser Cutters. These are great for boutique jewelers or specialty shops.

Diode Laser Engravers

Diode lasers, such as the Longer Ray5 (5W-20W), are budget-friendly at $500-$1,000 but need pre-treatment (like paint or marking paper) because their 450nm wavelength passes through clear glass. They’re best for small projects, like etching coasters or tiny mirrors, per Tom’s Hardware. They’re a solid pick for hobbyists on a tight budget.

Industrial Laser Engravers

For high-volume production, industrial CO2 or UV lasers like the Epilog Fusion Pro 48 or FUJIAN BAINENG’s CNC Glass Engraving Machine offer large beds (up to 1200x900mm) and blazing speeds (up to 4m/s). Costing $20,000-$50,000, they’re built for mass-producing architectural glass, mirrors, or bulk glassware, per STYLECNC. BAINENG’s CNC model excels at 2D/3D designs with CE/ISO-certified precision.

Hybrid Laser Engravers

Hybrid machines, like the Gravotech LS900 Edge, combine CO2 and fiber lasers to engrave glass and metals. With beds around 12”x18” and costs of $15,000-$30,000, they’re ideal for businesses needing versatility, like retail shops engraving glassware and metal tags, per Gravotech.

A 40W-60W CO2 laser with a rotary attachment is a versatile starting point for most glass engraving tasks, balancing power, cost, and capability.

Comparing Laser Engraving to Other Glass Engraving Methods

Not sure if laser engraving is the best fit for your glass projects? Let’s compare it to two other popular methods: sandblasting and rotary engraving. Each has its strengths, depending on what you’re aiming for.

Laser Engraving uses a beam to etch the glass surface, delivering pinpoint precision (up to 1200 DPI) for logos, text, or photos. It’s clean, non-contact, and fast, taking 2-5 minutes for small designs, per JustLaser. However, it’s limited to surface etches (0.01-0.1mm) and can be pricey for industrial models.

Sandblasting shoots abrasives like aluminum oxide through a stencil to carve deep etches (up to 1mm), ideal for large, frosted areas like privacy panels or shower doors. It offers a smooth, premium finish but is messy, requiring a compressor, cabinet, and protective gear, with setup and cleanup taking 10-20 minutes, per Delphi Glass.

Rotary Engraving uses spinning diamond or carbide bits to cut into glass, creating deep, tactile etches (up to 0.5mm) for textured designs. It’s versatile but slower (5-10 minutes) and dustier, needing dust collection systems, per Gravotech.

Here’s a quick comparison:

| Feature | Laser Engraving | Sandblasting | Rotary Engraving |

|---|---|---|---|

| Precision | High (1200 DPI) | Moderate (stencil-based) | Moderate (tool-dependent) |

| Depth | Surface (0.01-0.1mm) | Deep (up to 1mm) | Deep (up to 0.5mm) |

| Speed | Fast (2-5 min) | Slower (10-20 min) | Slow (5-10 min) |

| Setup | Laser, software, small space | Compressor, cabinet, gear | Rotary tool, dust collection |

| Cost | $500-$50,000 | $1,000-$6,000 | $1,000-$10,000 |

| Best For | Detailed designs, mirrors | Large frosted areas | Textured, deep etches |

Laser engraving, like BAINENG’s CNC Glass Engraving Machine, is your best bet for precision and speed, sandblasting for deep frosting, and rotary engraving for tactile designs, per Glass Etching Fever.

Key Features to Look for in a Glass Engraving Laser Machine

Picking the right machine means focusing on features that make your work easier and safer. Here’s what to prioritize:

- Laser Power: A 40W-60W CO2 laser is ideal for most glass; 3W-5W UV for delicate work; 100W+ for industrial speed, per Epilog.

- Bed Size: Choose 400x400mm for small glassware or 1200x900mm for panels, per Gravotech.

- Rotary Attachment: Essential for curved items like bottles or vases, included with xTool or BAINENG models, per OMTech.

- Software Compatibility: LightBurn for intuitive control of vectors and photos, per LightBurn.

- Autofocus and Camera: Ensures precise focus and alignment, like Epilog’s IRIS Camera, per Epilog.

- Fume Extraction: Integrated exhaust or air assist removes glass dust and fumes, keeping your workspace clean, per Gravotech.

- Safety Features: Look for enclosed designs, auto shut-off, and Class 1 safety ratings to protect against laser exposure, per CNET.

Checklist for Buyers:

- [ ] Sufficient laser power for your glass type

- [ ] Bed size matching your project scale

- [ ] Rotary attachment for curved glass

- [ ] LightBurn-compatible software

- [ ] Autofocus/camera for precision

- [ ] Fume extraction for safety

- [ ] Enclosed design with safety features

These features ensure a machine that’s user-friendly, safe, and built for stunning results.

Applications of Glass Engraving Laser Machines

Glass engraving laser machines open up a world of possibilities for creative and commercial projects. Here are some inspiring ways to use them:

- Personalized Glassware: Etch names, dates, or logos on wine glasses, mugs, or tumblers for weddings, birthdays, or corporate gifts, selling for $20-$50 per set on Etsy.

- Architectural Glass: Create frosted patterns or logos on windows, shower doors, or office partitions for privacy and style, perfect for upscale offices or hotels, per BAINENG.

- Mirrors: Engrave custom designs or monograms on mirrors for home decor or boutique sales, fetching $50-$300. Backlit etched mirrors are a 2025 trend, per Algolaser.

- Awards and Trophies: Etch glass plaques or crystal awards with text or logos for corporate or sports events, adding a premium touch, per Epilog.

- Photo Etchings: Transfer grayscale photos onto glass frames or ornaments for heartfelt keepsakes, per Monport.

- Branding and Retail: Etch logos on glassware, bottles, or display panels for restaurants, bars, or retail stores, boosting brand appeal, per Gravotech.

These applications show how glass engraving can create high-value products for profit or personal joy.

Benefits of Using Glass Engraving Laser Machines

Why go with a glass engraving laser machine? Here’s what makes them a game-changer:

- Unmatched Precision: Achieve 1200 DPI for intricate logos or text, outshining sandblasting’s stencil-based limits, per TechRadar.

- Lightning Speed: Small designs etch in 2-5 minutes, letting you churn out projects fast, per OMTech.

- Clean Process: No messy abrasives or chemicals—just a quick rinse, unlike sandblasting’s cleanup hassle, per JustLaser.

- Safe for Thin Glass: Non-contact etching minimizes cracking risks on 0.5-3mm glass, per xTool.

- Durable Designs: Etchings resist wear, fading, or washing, perfect for daily-use glassware or decor.

- Versatile: Etch flat panels, curved bottles, mirrors, or tempered glass with ease, per Gravotech.

A glass artist using BAINENG’s CNC machine raved, “It cut my production time in half while delivering flawless etches!” These benefits make laser engraving a top choice for quality and productivity.

How to Choose the Right Glass Engraving Laser Machine

Picking the perfect glass engraving laser machine can feel overwhelming, but here’s a step-by-step guide to make it easy:

- Assess Your Project Needs: For small glassware or mirrors, a desktop CO2 laser like the xTool P2 is plenty. For large panels or bulk production, go for an industrial model like BAINENG’s CNC Glass Engraving Machine, per STYLECNC.

- Consider Glass Type and Size: Ensure the machine handles soda-lime, borosilicate, or tempered glass. Choose a bed size of 400x400mm for small items or 1200x900mm for panels, per Gravotech.

- Set a Budget: Diode lasers ($500-$1,000) are great for hobbyists with pre-treatment; CO2 lasers ($2,000-$5,000) suit small businesses; UV ($5,000-$10,000) or industrial ($20,000-$50,000) for pros, per CNET.

- Prioritize Key Features: Look for a rotary attachment for curved glass, autofocus for precision, and LightBurn compatibility for ease, per Epilog.

- Check Space Constraints: Desktop models fit small studios (e.g., 600x400x200mm); industrial machines need dedicated spaces, per Gravotech.

- Research Brand Support: Choose brands like BAINENG, xTool, or Epilog with strong customer service and warranties, per CNCSourced.

Here’s a quick comparison of machine types to guide your choice:

| Machine Type | Bed Size | Power | Cost | Best Use |

|---|---|---|---|---|

| CO2 Desktop (xTool P2) | 495x279mm | 55W | $2,000-$3,000 | Glassware, mirrors |

| UV (ComMarker Omni 1) | 200x200mm | 5W | $5,000-$10,000 | Delicate glass |

| Industrial (BAINENG CNC) | 1200x900mm | 100W+ | $20,000-$50,000 | Panels, bulk production |

A 40W-60W CO2 laser is a versatile starting point for most glass engraving projects.

Top Brands and Models of Glass Engraving Laser Machines

Ready to shop? Here are some top brands and models for glass engraving in 2025, each excelling in specific use cases:

- xTool P2 (55W CO2): Desktop model with a 495x279mm bed, costing $2,000-$3,000. Perfect for glassware, mirrors, or small panels, with a rotary attachment for bottles, per CNET.

- Glowforge Pro (45W CO2): Compact, 495x279mm bed, $4,000-$5,000. Ideal for small businesses etching custom tumblers or coasters, with cloud-based software, per CNET.

- Epilog Fusion Pro 48 (80W CO2): Industrial powerhouse with a 1200x900mm bed, $20,000-$30,000. Built for mass-producing architectural glass or mirrors, with autofocus and IRIS Camera, per Epilog.

- FUJIAN BAINENG CNC Glass Engraving Machine: Industrial CO2 model with CNC precision, $20,000-$50,000. Excels at 2D/3D designs for panels or bulk glassware, CE/ISO-certified, per BAINENG.

- Gravotech LS100 (40W CO2): Compact, 12”x18” bed, $5,000-$8,000. Great for retail shops engraving glassware or awards, with a small footprint, per Gravotech.

Here’s a comparison to help you choose:

| Model | Power | Bed Size | Cost | Best Use |

|---|---|---|---|---|

| xTool P2 | 55W | 495x279mm | $2,000-$3,000 | Glassware, mirrors |

| Glowforge Pro | 45W | 495x279mm | $4,000-$5,000 | Small business |

| Epilog Fusion Pro 48 | 80W | 1200x900mm | $20,000-$30,000 | Industrial panels |

| BAINENG CNC | 100W+ | 1200x900mm | $20,000-$50,000 | Bulk production |

| Gravotech LS100 | 40W | 12”x18” | $5,000-$8,000 | Retail engraving |

These models offer a range of options for hobbyists, small businesses, and industrial fabricators.

Maintenance and Safety Tips for Glass Engraving Laser Machines

Keeping your glass engraving laser machine in top shape and staying safe are key to consistent, stunning results. Here’s how to do it:

- Maintenance:

- Clean Optics: Wipe lenses and mirrors weekly with isopropyl alcohol to ensure a sharp beam, per OMTech. Dirty optics can weaken etches.

- Check Cooling: Clear water cooling systems (CO2 lasers) or fans (diodes) of blockages to prevent overheating, per OMTech.

- Inspect Rotary Attachments: Ensure alignment for curved glass engraving to avoid skewed designs, per Gravotech.

- Safety:

- Use Enclosed Machines: Opt for Class 1 lasers (fully enclosed) to avoid eye exposure, or wear safety glasses for Class 4 open-frame models, per CNET.

- Ventilate Properly: Use a fume extractor or vent to remove glass dust and laser fumes, protecting your lungs, per Gravotech.

- Avoid Over-Etching: Too many passes can crack glass, especially thin or tempered pieces, so test settings first, per Focused Laser Systems.

- Troubleshooting:

- Faint Etches? Increase power slightly or clean optics.

- Uneven Designs? Check rotary alignment or ensure glass is flat.

Maintenance Checklist:

- [ ] Clean lenses/mirrors weekly

- [ ] Check cooling system monthly

- [ ] Inspect rotary attachment alignment

- [ ] Ensure proper ventilation

- [ ] Test settings on scrap glass

These steps keep your machine humming and your workspace safe.

Cost Considerations and ROI for Glass Engraving Laser Machines

Investing in a glass engraving laser machine can seem daunting, but the returns can be impressive. Here’s a breakdown of costs and potential ROI:

- Cost Breakdown:

- Diode Lasers: $500-$1,000, ideal for hobbyists with small projects (pre-treatment required).

- Desktop CO2 Lasers: $2,000-$5,000, great for small businesses engraving glassware or mirrors.

- UV Lasers: $5,000-$10,000, suited for precision work on delicate glass.

- Industrial Lasers: $20,000-$50,000, like BAINENG’s CNC models, for high-volume production, per STYLECNC.

- Cost Factors: Laser power, bed size, automation (e.g., CNC controls), and accessories (rotary attachment, fume extractor) drive prices.

- ROI Benefits:

- High Margins: Custom glassware sells for $20-$50 per piece; etched mirrors or panels fetch $200-$1,000, boosting revenue, per Algolaser.

- Fast Production: Etching small designs in 2-5 minutes cuts labor costs, allowing high output.

- Low Operating Costs: Lasers use no abrasives or stencils, keeping expenses minimal.

- Market Demand: Personalized glassware, branded retail items, and architectural glass are hot in 2025, driving sales.

- Used vs. New: Pre-owned machines from Epilog or BAINENG can save 20-30%, but verify maintenance history to avoid costly repairs, per CNCSourced.

- Financing Options: Suppliers like BAINENG and xTool offer financing to make high-end models accessible. Contact suppliers for quotes, as prices vary by region.

For a small business, a $2,000 CO2 laser could pay for itself in months by selling 100 etched glasses at $30 each, while industrial setups yield higher returns for large orders.

Common FAQs About Glass Engraving Laser Machines

Got questions? Here are answers to some common queries about glass engraving laser machines:

What glass types can be engraved with a laser?

Most glass—soda-lime (used in bottles), borosilicate (labware), and tempered—etches beautifully. Avoid lead crystal, which can crack under laser heat, per Focused Laser Systems.

How deep are laser engravings on glass?

CO2 lasers create surface etches (0.01-0.1mm); UV lasers can reach 0.1-0.2mm for slightly deeper, finer work. Multiple passes can deepen etches but risk cracking, per Thunder Laser.

Do I need special software for laser engraving?

Yes, software like LightBurn or RDWorks is ideal for precise control, letting you upload vector files (SVG) or adjust photos for etching, per LightBurn.

Is laser engraving safe for thin glass?

Absolutely, the non-contact process minimizes cracking risks on 0.5-3mm glass if you use low power and test settings first, per xTool.

How long does it take to engrave glass?

Small designs (50x50mm) take 2-5 minutes with a laser; larger or complex patterns may need 10-30 minutes, per OMTech.

Final Thought

Glass engraving laser machines are your key to creating personalized, high-value designs that stand out, from custom wine glasses to frosted mirrors and architectural panels. With options like CO2 lasers for versatility, UV lasers for precision, and industrial models like FUJIAN BAINENG’s CNC Glass Engraving Machine for bulk production, there’s a machine for every project. Laser engraving beats sandblasting and rotary methods for speed and detail, making it perfect for most glasswork. Start with a 40W CO2 laser, use tricks like the wet paper towel for smoother etches, and test settings on scrap glass. In 2025, you’re ready to craft designs that sell big, impress clients, or spark joy.

Ready to etch stunning glass designs? Explore top laser engravers from BAINENG, xTool, or Epilog today, and share your project ideas in the comments—I’d love to hear what you’re creating!