Glass Edge Grinding vs Beveling Comparison Guide

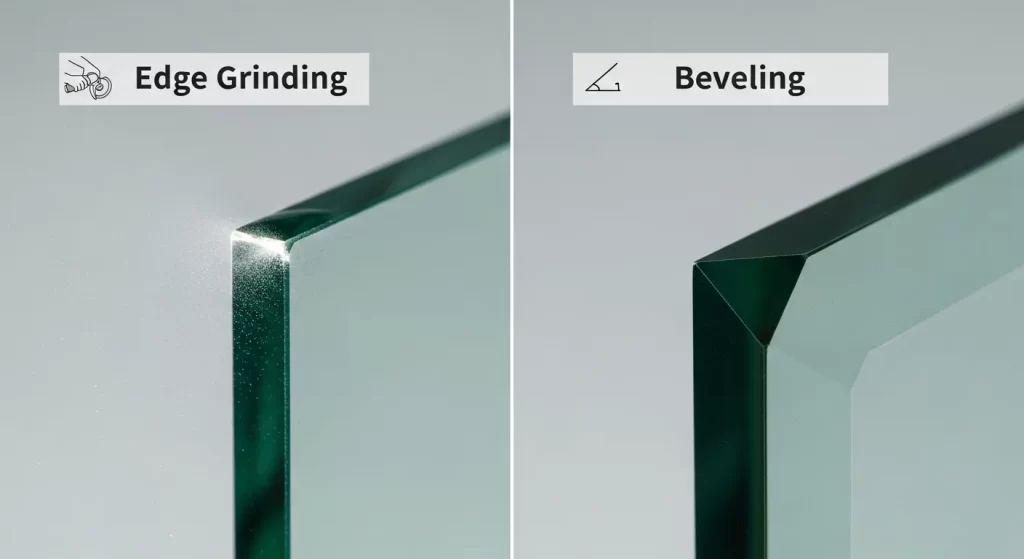

The glass edge grinding vs beveling comparison is a critical topic in glass fabrication, yet it is a source of frequent confusion. While both are essential processes in finishing glass, they represent different stages and serve fundamentally different purposes. Grinding is the foundational, mechanical action of shaping a glass edge. Beveling is the complete, decorative process of creating an angled face on the glass, which itself begins with grinding. Understanding this distinction between a foundational action and a complete decorative process is the key. It allows for accurate specification, better quality control, and a deeper appreciation of the craft.

What is the Fundamental Difference in Purpose?

The fundamental difference lies in their primary purpose. Glass edge grinding is a functional, formative process. Its main goal is to shape the edge, remove sharp arrises for safety, and prepare the glass for further finishing. Glass beveling is a purely decorative process. Its sole purpose is to create a beautiful, light-refracting angled border that enhances the aesthetic value of the glass.

How Does Grinding Relate to Edging?

Grinding is the first and most aggressive step in the broader process of edging. As the article on glass beveling vs edging difference explains, edging is the complete process of finishing the perimeter of a glass sheet. This process always starts with grinding to establish the profile (e.g., flat or pencil shape). It is then followed by fining and polishing to achieve a smooth, finished look. Therefore, grinding is a component of edging.

How Does Grinding Relate to Beveling?

Similarly, grinding is also the essential first step in the beveling process. To create the angled face of a beveled glass edge, the material must first be removed by coarse diamond grinding wheels. Beveling is the complete journey from this initial grind to the final, brilliant polish. Grinding is simply the starting point of that journey. It is the action that makes the decorative process possible.

What is Glass Edge Grinding in Detail?

Glass edge grinding is a subtractive machining process. It uses coarse-grit, metal-bonded diamond wheels to aggressively shape a raw, cut glass edge. It is a necessary, functional step that transforms a dangerous, fragile edge into a safe and dimensionally accurate one. The outcome of the grinding process alone is a rough, opaque surface that is not considered a final decorative finish.

What Are the Primary Objectives of Grinding?

The primary objectives of the grinding stage are clear and functional.

- Shaping: To machine the edge into a specific profile, such as a flat edge with arrises or a rounded pencil edge.

- Safety: To remove the razor-sharp corners and edges left after cutting, making the glass safe for handling and installation.

- Dimensioning: To grind the glass to a precise final size with tight tolerances.

- Preparation: To create a uniform surface that is ready for the subsequent, finer stages of the finishing process.

What Tools and Machinery Are Used for Grinding?

The tools used for grinding are designed for aggressive material removal. They consist of diamond particles held in a hard, durable metal bond. These metal-bond wheels can withstand the high pressure and friction of the grinding process. The machinery can range from a simple manual glass edge sanding machine for basic safety seaming to sophisticated, automated straight-line edgers or CNC work centers for creating precise profiles.

What is the Appearance of a Ground-Only Edge?

A ground-only edge has a distinctive appearance. It is opaque, with a milky or cloudy white look. The surface is rough to the touch. It is filled with the millions of microscopic fractures created by the coarse diamond abrasives. While it is safe to handle, it is not aesthetically pleasing. It is considered an unfinished or industrial-grade look. It is only acceptable in applications where the edge will be completely concealed.

What is Glass Beveling in Detail?

Glass beveling is a multi-stage, decorative finishing process. It creates a distinct, angled cut on the face of the glass near its perimeter. This process begins with an aggressive grinding stage to create the angle. It is then followed by a meticulous sequence of fining and polishing. This transforms the rough, ground surface into an optically clear, brilliant finish that refracts light like a prism.

What is the Primary Objective of Beveling?

The primary objective of beveling is purely aesthetic enhancement. It is an intentional design choice made to add a sense of luxury, depth, and artistry to a piece of glass. The angled surface is specifically designed to interact with light. This creates a sparkling, prismatic effect that elevates the glass from a simple material to a decorative feature. The use of beveling glass for interior design is a testament to its powerful visual impact.

How is the Beveling Process Structured?

The beveling process is structured as a gradual refinement. This systematic approach is detailed in our guide on how glass beveling machines work.

- Stage 1: Rough Grinding: Coarse diamond wheels grind the glass to establish the bevel's angle and width.

- Stage 2: Fining/Honing: Progressively finer resin-bond diamond wheels remove the deep scratches from the grinding stage.

- Stage 3: Polishing: Felt polishing wheels are used with a cerium oxide slurry to create the final brilliant, transparent shine.This multi-stage process is essential. You cannot achieve a high-quality polish without the preceding preparatory stages.

What is the Appearance of a Finished Beveled Edge?

A finished beveled edge is a stunning visual feature. The angled surface is perfectly transparent and optically flawless. It has a brilliant, diamond-like shine. As light passes through it, it creates a crisp, clean line where it meets the flat face of the glass. The bevel itself acts as a prism. It creates a border of sparkling, rainbow-colored light around the perimeter of the glass. It is a premium finish that signifies the highest level of craftsmanship.

Head-to-Head Comparison: The Action vs. The Process

This glass edge grinding vs beveling comparison is best understood as a comparison between a single action and a complete process. Grinding is a foundational step, while beveling is a comprehensive journey that includes grinding as its starting point.

| Feature | Glass Edge Grinding | Glass Beveling |

| Definition | The initial, aggressive action of shaping an edge. | The complete, multi-stage process of creating an angled face. |

| Primary Goal | Functional: Safety, shaping, dimensioning. | Decorative: Aesthetics, light refraction, luxury. |

| Location | Works on the perimeter/thickness of the glass. | Works on the face of the glass, at an angle. |

| Outcome | A rough, opaque, unfinished surface. | A brilliant, transparent, polished surface. |

| Role in Finishing | The first step of almost every finishing process. | A complete, high-end decorative finishing process. |

| Tools Used | Coarse, metal-bonded diamond wheels. | A sequence of grinding, fining, and polishing wheels. |

Can Grinding Be a Final Finish?

In almost all commercial and residential applications, grinding is not considered a final finish for an exposed edge. A ground-only edge is aesthetically unpleasing and can be structurally weaker due to the micro-fractures on its surface. However, there are very specific industrial applications where a ground edge may be sufficient.

A ground edge is only acceptable when it will be completely hidden from view and is not subject to significant thermal stress. For example, a piece of glass that will be set deep into a metal U-channel or a wooden frame may only require a ground edge. In these cases, the primary concerns are dimensional accuracy and safety during assembly. The final appearance of the edge is irrelevant because it will never be seen.

How Does Grinding Serve as the Foundation for Beveling?

Grinding is the indispensable foundation upon which every bevel is built. The angled, decorative surface of a bevel is created by removing a wedge-shaped section of glass from its face. This material removal is accomplished during the initial grinding stages of the beveling process. It is impossible to create a bevel without first grinding the glass.

The initial grinding wheels in an automatic glass beveling machine are coarse, aggressive tools. They are set at the desired angle. They do the heavy lifting of removing the bulk of the glass material to establish the bevel's width and angle. All subsequent stages of fining and polishing are dedicated to smoothing and refining this ground surface. Therefore, the quality of the initial grind directly impacts the quality of the final bevel. A consistent, well-executed grind is the prerequisite for a flawless polish.

How Do the Respective Machines Differ?

The machines used for standard edge grinding and for beveling are designed differently to accommodate their distinct purposes. While a versatile CNC machine can be programmed for both, dedicated, high-production machines are specialized for one task or the other. This specialization is key to their efficiency.

What is the Design of a Standard Edge Grinder?

A standard edge grinder, as discussed in the guide on how to choose the best glass edger, is designed to work on the thin perimeter of the glass. Its spindles are oriented vertically. This allows the wheels to process the edge as the glass lies flat or is fed through the machine. The goal is to create a profile, like a flat or pencil edge, on this narrow surface. The entire machine is built to support this perpendicular interaction between the wheel and the glass edge.

What is the Design of a Beveling Machine?

A beveling machine is designed to work on the face of the glass at an angle. On a straight-line beveling machine, the entire bank of spindles is physically tilted to the desired bevel angle. On a CNC shape beveler, the machine may use a 5-axis head or specially shaped tools to achieve this angle. The entire mechanical design is focused on allowing the wheels to approach and process the glass surface at a precise, controlled angle. This angled approach is the defining characteristic of the machine's design.

How Do the Final Outcomes Compare Visually and Functionally?

The final outcomes of a ground-only edge and a finished bevel are worlds apart, both visually and functionally. One is an intermediate, industrial finish. The other is a final, high-end decorative feature. This difference is the most important takeaway in the glass edge grinding vs beveling debate.

What is the Visual Difference?

The visual difference is stark.

- Ground Edge: Opaque, milky-white, and rough. It has a matte, unfinished appearance that diffuses light. It looks like a work in progress.

- Beveled Edge: Perfectly transparent, brilliant, and smooth. It has a high-gloss shine that reflects and refracts light, creating a sparkling, jewel-like effect. It looks like a finished work of art.

What is the Functional Difference?

The functional difference is equally clear.

- Ground Edge: Its primary functions are to make the glass safe to handle and to bring it to a precise dimension. It is a necessary preparatory step.

- Beveled Edge: Its primary function is decoration. While the polishing process does add strength, its main purpose is to add aesthetic value and visual interest to the final product. It is a deliberate design choice.

Clarifying the Hierarchy of Finishing Terms

To achieve true glass beveling and edging mastery, it is essential to understand the hierarchy of these related terms. They are not interchangeable. They describe different levels of the finishing process.

- Grinding: This is the foundational action. It is the mechanical process of using a coarse abrasive to shape glass.

- Edging: This is a complete process. It involves finishing the perimeter of the glass. This process includes grinding as its first step, followed by fining and polishing.

- Beveling: This is also a complete process. It involves creating a decorative, angled face on the glass. This process also includes grinding as its first step, followed by fining and polishing on the angled surface.

Therefore, you grind an edge to begin the process of edging it. You grind a face to begin the process of beveling it. Grinding is the starting point for both.

Conclusion

The glass edge grinding vs beveling comparison clarifies a fundamental concept in glass fabrication. Grinding is the essential, foundational action of shaping glass with an abrasive. It is a functional, intermediate step that creates a safe but unfinished edge. Beveling is a complete, multi-stage decorative process. It begins with grinding but continues through fining and polishing to create a brilliant, high-value aesthetic feature. Understanding that one is a single step and the other is a complete journey is the key to specifying, producing, and appreciating high-quality finished glass.