Glass Beveling vs Edging Difference Explained

The glass beveling vs edging difference is a crucial distinction in the world of glass fabrication. While both are premium finishing processes that transform a raw, cut piece of glass into a safe and beautiful product, they serve fundamentally different purposes and create distinct visual effects. Edging is a functional and aesthetic treatment of the glass's narrow perimeter.1 Beveling is a purely decorative process that creates an angled cut on the face of the glass. Understanding this difference is essential for designers, architects, and consumers. It ensures the correct specification for achieving the desired outcome in any project.

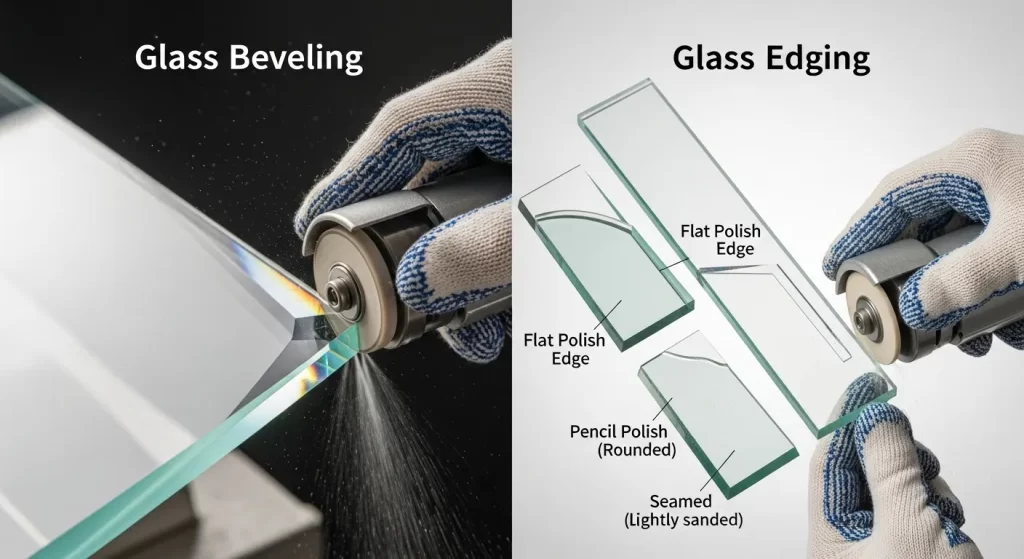

What is the Core Difference Between Glass Beveling and Edging?

The core difference between glass beveling and edging lies in their purpose and location on the glass. Edging shapes and finishes the thin profile of the glass's perimeter for safety and a clean look. Beveling creates a decorative, angled cut on the face of the glass, near the edge, to create a prism-like, light-refracting effect.2

Think of it in terms of tailoring a garment. Edging is like hemming a pair of trousers. It creates a clean, durable, and finished line that is both functional and neat. Beveling, on the other hand, is like adding decorative embroidery to the cuff. It is a purely aesthetic choice designed to add style, character, and a sense of luxury.3 One is a necessary finish; the other is a deliberate embellishment. This fundamental distinction is the first step toward achieving glass beveling and edging mastery.

What is Glass Edging in Detail?

Glass edging is the process of machining the narrow edge of a glass sheet after it has been cut.4 Its primary objectives are to make the glass safe to handle by removing the razor-sharp edges and to provide a clean, aesthetically pleasing profile. It is a standard and necessary step for almost all finished glass products where the edge will be exposed.

What Are the Primary Goals of Edging?

The goals of glass edging are multifaceted.5 They combine practical necessity with aesthetic refinement.

- Safety: The most immediate goal is to remove the incredibly sharp edges left after cutting. A simple seamed or sanded edge makes the glass safe to handle and install.6

- Strength: The edging process, particularly polishing, removes the microscopic flaws and fissures from the cut edge. These flaws are stress concentrators. Removing them makes the edge significantly more durable and resistant to chipping or cracking.

- Aesthetics: A finished edge, such as a flat polish or pencil polish, provides a clean, high-quality look.7 It is a mark of a professionally finished product.

What Are Common Types of Edged Profiles?

There are several standard edge profiles, each with its own look and common application.

- Flat Polish: This is the most common polished edge. It features a perfectly flat, 90-degree edge with two small, 45-degree arrises (or chamfers) on the top and bottom corners. It provides a clean, sleek, and modern look. It is the standard for frameless shower doors, glass tabletops, and shelving.

- Pencil Polish (C-Edge): This profile has a rounded, convex shape, like a pencil.8 It offers a softer, more traditional look. It is frequently used on mirrors, glass protectors for furniture, and some shelf designs.

- Seamed Edge: This is the most basic edge finish. It involves lightly sanding the sharp corners of the glass just enough to make it safe to handle.9 The edge itself remains opaque and has a slightly rough, matte finish. This is used when the edge will be completely hidden in a frame or channel. A basic glass edge sanding machine is used for this process.

How is a Polished Edge Achieved?

A polished edge is achieved through a multi-stage process of grinding and polishing. It is not a single action. First, a coarse diamond wheel grinds the edge to the desired shape (e.g., flat or pencil). This is followed by one or more finer-grit "fining" wheels. These remove the deep scratches from the grinding stage. Finally, a felt polishing wheel is used with a cerium oxide slurry. This chemo-mechanical process creates the final brilliant, transparent shine. This detailed process is covered in our guide to polishing glass edges like a pro.

What is Glass Beveling in Detail?

Glass beveling is a decorative process that grinds and polishes an angled surface onto the face of the glass near its edge.10 The sole purpose of a bevel is aesthetic. It creates a sophisticated, dimensional look. It also acts as a prism, refracting light into a spectrum of colors. This adds a sense of depth, luxury, and artistry to the glass piece.

What is the Primary Goal of Beveling?

The primary goal of beveling is to enhance the beauty of the glass. It is an intentional design choice. It is meant to make the glass a decorative focal point. The angled surface catches light in a dynamic way. This is very different from a flat piece of glass. This effect adds visual interest and a sense of high value. The use of beveling glass for interior design is a classic technique to elevate the elegance of a space.

How Are Bevels Measured and Specified?

Bevels are primarily specified by their width. The width is the measurement of the angled face, from the edge of the glass to the point where the bevel meets the flat surface of the glass. Common bevel widths range from 1/2 inch to 1 1/2 inches.11 A wider bevel will produce a more dramatic and noticeable prismatic effect. The choice of width depends on the size of the glass and the desired design impact. A wider bevel is generally considered more luxurious.

How is a Bevel Created?

A bevel is created using a sequential grinding and polishing process, similar to edging but performed on an angle. Specialized machines use a series of angled wheels.12 The first wheels are coarse diamond grinders that remove the glass to create the angled face. These are followed by finer honing wheels to smooth the surface. Finally, angled polishing wheels are used with cerium oxide to bring the bevel to a brilliant, optically clear finish. The intricacies of this process are detailed in our guide on how glass beveling machines work.

Head-to-Head Comparison: Glass Beveling vs Edging

To fully clarify the glass beveling vs edging difference, a direct comparison is the most effective tool. This table breaks down the key attributes of each process, providing a clear, at-a-glance reference for their distinct characteristics and applications.

| Feature | Glass Edging | Glass Beveling |

| Purpose | Functional and aesthetic. | Purely decorative. |

| Location of Work | On the narrow perimeter (thickness) of the glass. | On the face of the glass, near the edge. |

| Primary Goal | To create a safe, durable, and finished edge profile. | To create a decorative, light-refracting angled border. |

| Final Appearance | A smooth, finished profile (e.g., flat, rounded). | An angled, prismatic border. |

| Effect on Light | Minimal effect. | Refracts light like a prism. |

| Common Profiles | Flat Polish, Pencil Polish, Seamed Edge. | N/A (Specified by width, e.g., 1-inch Bevel). |

| Common Apps | Shower doors, railings, functional tabletops. | Decorative mirrors, high-end furniture, cabinet inserts. |

| Cost | Less expensive. | More expensive. |

When Should You Choose Edging Over Beveling?

You should choose edging when the primary requirements for the glass are safety, functionality, and a clean, finished appearance. Edging is the standard and most practical choice for the vast majority of glass applications where the edge will be visible. It provides a beautiful and durable finish without the added decorative complexity and cost of a bevel.

Edging is the clear choice for:

- Frameless Shower Doors: A flat polished edge provides a clean look and is essential for the proper fitment of hinges and seals.13

- Glass Railing Systems: Safety and durability are the top priorities. A robust polished edge is the industry standard.

- Functional Tabletops and Shelves: A flat or pencil polish provides a safe, durable, and aesthetically pleasing finish that is easy to clean.14

- Budget-Conscious Projects: A standard polished edge is significantly more cost-effective than a beveled edge. This makes it the default choice for most projects. The cost difference can be substantial, especially on large projects.

When is Beveling the Superior Choice?

Beveling is the superior choice when the glass is intended to be a decorative centerpiece. It is an investment in artistry. It is chosen when the goal is to add a significant element of design, luxury, and visual interest. A beveled edge transforms the glass from a simple building material into a statement piece.

Beveling is the ideal choice for:

- Decorative Mirrors: A beveled edge on a mirror creates a "frame within a frame" effect. It adds depth and elegance.

- High-End Furniture: A beveled glass tabletop or cabinet insert adds a touch of sophistication and craftsmanship. This increases the perceived value of the entire piece.

- Cabinet Doors and Transoms: Beveled glass inserts in kitchen cabinets, display cases, or transom windows create a classic, custom look.16

- Making a Design Statement: When the budget allows and the design calls for a touch of brilliance, a bevel is an unparalleled choice. The use of beveled glass is a hallmark of luxury interior design.

Can a Piece of Glass Have Both Edging and a Bevel?

Yes, a piece of glass can and, in fact, must have both a finished edge and a bevel. This is a common point of confusion. The bevel is the angled cut on the face of the glass. However, after this angle is cut, there is still a small, vertical edge remaining at the very perimeter of the glass. This outer edge, sometimes called the "arris" or "face," must be finished for safety. It is typically seamed or lightly polished. So, a beveled piece of glass technically has two finished surfaces: the wide, angled bevel and the thin, finished outer edge.

How Do Machines for Beveling and Edging Differ?

While advanced, versatile CNC machines can be programmed to perform both processes, dedicated machines for beveling and edging are structurally different. They are designed and optimized for the unique requirements of each task. A workshop focused on high-volume production will typically have separate, specialized machines for each process.

What Defines a Glass Edging Machine?

A glass edging machine is designed to work on the perimeter or thickness of the glass.17 Its grinding and polishing wheels are typically oriented to be perpendicular to the edge being worked. These machines are engineered to create a specific profile (flat, pencil, etc.) with high precision and a perfect polish. The guide on how to choose the best glass edger details the features to look for in this type of specialized equipment.

What Defines a Glass Beveling Machine?

A glass beveling machine is designed to work on the face of the glass at an angle. In a straight-line beveling machine, the entire bank of spindles is tilted to the desired bevel angle. In a more flexible CNC shape beveler, the machine uses specialized, angled tooling or a 5-axis head to create the bevel. The entire design of the machine is focused on creating and polishing this angled surface. The mechanics are detailed in our article where the automatic glass beveling machine is explained.

Can One Machine Do Both?

Yes, a sophisticated 5-axis CNC glass working center can be programmed to perform both standard edging and beveling.20 This provides incredible flexibility for a custom fabrication shop. The machine can use one set of tools to create a polished edge and another set to create a bevel, all in a single setup. However, for high-volume, standardized production, dedicated straight-line machines are far more efficient. They are built for speed and throughput on a single, repetitive task.

Conclusion

The glass beveling vs edging difference is a clear choice between functional elegance and decorative artistry. Edging is the essential process of creating a safe, durable, and beautifully finished profile on the glass's perimeter.21 Beveling is the creative process of adding a luxurious, light-refracting angled border to its face.22 One is a standard of quality; the other is a statement of style. By understanding the unique purpose, process, and applications of each, you can specify with confidence. You can ensure that every piece of glass is finished perfectly for its intended purpose.