Beveling vs. Edging: The Complete Guide to Glass Finishing Techniques

The debate over beveling vs. edging is a common point of confusion for those new to glass design. Both are essential finishing techniques, but they serve entirely different purposes. Choosing the wrong one can mean the difference between a project that looks sleek and modern, and one that feels classic and decorative. In short, edging is a functional finish, while beveling is a decorative one.

Understanding this core difference is the key to selecting the right finish for your glass. Edging refers to shaping and polishing the thin profile (the edge) of the glass.1 This is done for safety and to create a clean, finished look. Beveling, on the other hand, is a more complex process. It involves cutting and polishing an angled border on the face of the glass. This creates a beautiful, prismatic effect that refracts light.

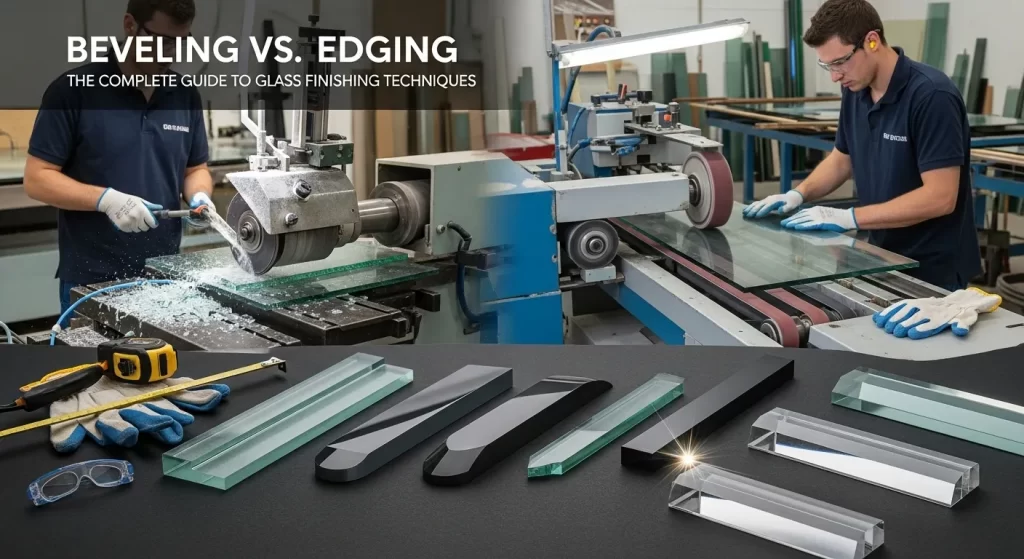

This guide will provide a complete overview of beveling vs. edging. We will explore the process for each, compare the different styles, and explain the machinery involved. These expert insights will help you choose the perfect finish for your mirrors, tabletops, or shower doors.

What is the Core Difference Between Beveling vs. Edging?

The core difference is purpose and location. Edging finishes the thin edge profile for safety and a clean look (like a flat or pencil polish). Beveling is a decorative cut on the face of the glass, creating an angled border that refracts light.2

Think of it this way: edging is a necessity, while beveling is an upgrade. Nearly every piece of cut glass requires some form of edging to make it safe to handle. A bevel is an optional, stylistic choice that adds significant visual impact and cost.

An edged piece of glass will have a uniform thickness right to the very edge. A beveled piece will have a border, typically 1/2 inch to 1 1/2 inches wide, where the glass thins out as it approaches the edge. This angled surface creates a "frame" effect and is the source of its signature rainbow-like prism.

What is Glass Edging? (The Functional Finish)

Glass edging is the process of finishing the sharp, raw edge of a glass sheet after it has been cut.3 This is a standard and essential step in glass fabrication. It ensures the glass is safe and durable. The finished look can range from a basic sanded edge to a brilliant, crystal-clear polish.

Why is Glass Edging Necessary?

Edging is necessary to remove the razor-sharp, dangerous edge left after cutting. It smooths the edge, making the glass safe to handle.4 It also strengthens the glass by removing micro-fissures, which helps prevent future chips and cracks.

When glass is cut, the resulting edge is incredibly sharp.5 It poses a significant safety hazard. The edging process removes this sharp edge. It also removes the tiny, invisible micro-fissures that are created during the cut. These fissures are stress points. They make the raw edge brittle and prone to chipping or cracking. By grinding and polishing these fissures away, the edge becomes much stronger and more durable.

What are the Most Common Types of Edges?

The "edge profile" refers to the shape you give the edge. While many decorative profiles exist, a few common types cover most applications:

- Seamed Edge: This is the most basic and least expensive finish. The sharp corners (or arrises) are lightly sanded off.6 The edge itself remains flat and has a matte, unfinished look. This is used when the edge will be completely hidden inside a frame. You can learn more about this in the glass edge sanding machine guide.

- Flat Polish: This is the most popular edge for modern, frameless glass. The edge is ground perfectly flat and perpendicular to the glass surface. It is then polished to a brilliant, shiny, and clear finish. Small 45-degree chamfers are added to the top and bottom corners to remove sharpness.7 This is the standard for shower doors, shelves, and many glass tabletops.

- Pencil Polish (C-Edge): This edge has a soft, rounded, C-shaped profile.8 It is polished to a shiny finish. This is a common choice for mirrors, furniture protectors, and tabletops where a softer look is desired.

- Ogee Edge: This is a more decorative, S-shaped edge profile. It is often used on thicker glass tabletops to add a classic, formal touch.

How is a Polished Edge Created?

A polished edge is not created in a single step. It is a multi-stage process that requires a sequence of grinding and polishing wheels.9

- Rough Grinding: The process begins with coarse-grit diamond grinding wheels. These wheels aggressively shape the edge into the desired profile (e.g., flat or pencil).10

- Fining (Sanding): The glass then moves to a series of finer-grit resin-bond diamond wheels. These "fining" wheels smooth out the rough surface left by the grinders.

- Polishing: The final step uses a felt or composite polishing wheel. This wheel is combined with a liquid slurry containing cerium oxide. Cerium oxide is a polishing compound that creates a chemical-mechanical reaction with the glass.11 It produces the final, brilliant, crystal-clear shine.

This process is a key part of polishing glass edges like a pro. It requires precision and a good understanding of how to polish the edge of glass safely.

What is Glass Beveling? (The Decorative Cut)

Glass beveling is a sophisticated, decorative process.12 It involves cutting and polishing an angled border on the face of the glass, near the edge. This is not a finish on the edge itself. It is a stylish feature added to the surface. A Bevel is a type of sloped edge.

What is the Aesthetic Purpose of a Bevel?

The aesthetic purpose of a bevel is to create a beautiful, angled border that refracts light.13 This angled surface acts like a prism, splitting light into colors. It adds a sense of depth, luxury, and visual interest to the glass.

The bevel creates a "frame within a frame" effect. This is why it is so popular on frameless mirrors. The prismatic effect adds sparkle and life to the piece. Sunlight or room light passing through the bevel creates a rainbow of colors. This effect is a key element of beveling glass for interior design. It instantly makes a piece of glass look more expensive and custom-made.

How are Bevels Measured? (Width vs. Thickness)

Bevels are measured by their width, not the thickness of the glass. The width is the measurement of the angled cut, from the outer edge of the glass inward to the point where the bevel stops. Common bevel widths include:

- 1/2 inch

- 3/4 inch

- 1 inch

- 1 1/2 inch

The maximum width of the bevel is limited by the thickness of the glass. A very wide bevel requires a thicker (and more expensive) sheet of glass. You cannot put a 2-inch wide bevel on a 1/4-inch thick piece of glass. The glass would become razor-thin at the edge. A common rule is that the glass should be at least 3/16-inch thick for a 1/2-inch bevel. Thicker glass is needed for wider bevels.

How is a Bevel Created?

A bevel is created using a specialized machine. The process is similar to creating a polished edge, but it is much more complex. The wheels are set at a specific, shallow angle.

- Rough Grinding: The glass moves across a series of coarse-grit diamond grinding wheels set at the bevel angle. These wheels aggressively remove the material to create the angled surface.

- Fining (Smoothing): The beveled surface then passes over several finer-grit resin wheels. These wheels smooth out the rough grind lines.

- Polishing: The final step involves one or more felt polishing wheels. These are fed with a cerium oxide slurry. They polish the ground, angled surface to a flawless, brilliant shine.

This process requires a specialized machine, as detailed in this overview of how glass beveling machines work. After the bevel is polished, the remaining thin outer edge of the glass is typically given a basic seamed edge for safety.

Beveling vs. Edging: A Direct Comparison

This table provides a clear, side-by-side comparison of the two techniques. This is the core of the glass beveling vs. edging difference.

| Feature | Glass Edging | Glass Beveling |

| Primary Purpose | Functional: Safety and durability. | Decorative: Aesthetics and style. |

| Location of Work | The thin profile (edge) of the glass. | The front face of the glass, near the edge. |

| Final Look | A clean, finished edge profile (flat, round, etc.). | An angled, prismatic border. |

| Effect on Light | Minimal. A polished edge is clear. | Significant. Refracts light like a prism. |

| Necessity | Almost always required for safety. | A purely optional, decorative upgrade. |

| Common Use | Frameless shower doors, shelves, most tabletops. | Mirrors, decorative tabletops, cabinet glass. |

| Cost | Standard cost of finishing. | A premium-cost, value-adding process. |

What Machinery is Used for Edging and Beveling?

The machinery used for these processes is highly specialized. A glass shop will have different machines for each task. The level of automation dictates the speed and precision of the finish.

What is a Straight-Line Beveling Machine?

A straight-line beveling machine is a large, automated machine.14 It creates bevels on the straight edges of glass. The glass is fed through the machine on a conveyor. It passes a series of angled grinding and polishing wheels to create the finished bevel.

These machines are the workhorses of high-production facilities. They produce mirrors and rectangular tabletops with perfect consistency. A more detailed look can be found in this straight-line beveling machine overview. The high degree of automation is explained in this article on automatic glass beveling machine explained.

How are Curved or Shaped Bevels Made?

Curved bevels are made on specialized CNC (Computer Numerical Control) shape beveling machines. The glass is held stationary (often by vacuum). A rotating tool head with smaller wheels moves around the glass, grinding and polishing the curved profile.

This process is much slower and more complex. It is used for custom-shaped mirrors or tabletops (circles, ovals, etc.). The difference in process and machinery is a key part of understanding glass shape beveling vs. straight beveling.

What Machine is Used for Basic Edging?

A glass edger, or edging machine, is used for basic edging.15 Like bevelers, these come in straight-line and shape-edging models. A straight-line edger is designed to produce flat polished or pencil polished edges at high speed. A shape edger uses a CNC-guided head to follow the profile of a custom-cut piece. Learning how to choose the best glass edger depends on a shop's production needs.

Can Small or Hobbyist Machines Create Bevels?

Yes, small "all-in-one" grinders/bevelers are available for hobbyists and small studios.16 These are typically vertical, upright machines with interchangeable grinding and polishing wheels.17 The operator must manually guide the glass against the wheels.

These machines are perfect for artists creating stained glass or small decorative pieces.18 They offer a great deal of flexibility for a low cost. They are not suitable for large or high-production work. The creative applications for these are detailed in this guide to small glass beveling machine uses.

What are Common Problems and Considerations?

Choosing a finish involves a few practical considerations. These include cost, maintenance, and potential defects. Understanding these issues helps you manage your expectations.

What Causes a Hazy or "Cloudy" Bevel?

A hazy or cloudy bevel is almost always a polishing problem. It is caused by worn-out polishing wheels, a poor quality (or diluted) cerium oxide slurry, or a feed speed that is too fast, not allowing the wheels enough time to polish.

A quality bevel should be optically clear. Any haziness, or "white lines," indicates a problem in the fining or polishing stages. This can also happen if the grinding stage was too aggressive. The finer wheels may not be able to remove the deep scratches. This is one of the most common beveling problems and solutions fabricators face.

Does Beveling Weaken the Glass?

This is a common misconception. The process of grinding does introduce stress into the glass. But the final polishing stage smooths out the micro-fissures. This restores much of the edge's strength. A simple ground edge (not polished) is weaker. But a properly polished bevel is strong and durable. This is a key distinction in the glass edge grinding vs. beveling discussion.

What is the Cost Difference?

The cost difference is significant. A standard polished edge is a basic finishing cost. A beveled edge is a premium upgrade. Beveling is a more complex process. It requires more time and more expensive, specialized machinery. The cost also increases with the width of the bevel. A 1 1/2-inch bevel will cost considerably more than a 1/2-inch bevel.

How Do You Choose Between Beveling and Edging?

The choice between beveling and edging comes down to three factors: style, function, and budget.

When Should You Choose a Simple Polished Edge?

You should choose a simple polished edge in these situations:

- For a Modern, Minimalist Look: A clean, flat polished edge is the hallmark of modern design.

- For Frameless Shower Doors: A flat polish is the standard, functional, and safe choice.

- For Budget-Conscious Projects: A polished edge is the most affordable high-quality finish.19

- For Shelving: It provides a safe, durable, and clean finish.

When is a Beveled Edge the Right Choice?

You should choose a beveled edge in these situations:

- For a Traditional or Classic Look: Bevels add a formal, elegant touch.20

- For Frameless Mirrors: The bevel creates a "frame-like" finish.21 It is a classic pairing.

- As a Decorative Focal Point: Use it when the glass itself is meant to be a statement piece.

- To Add a Sense of Luxury: A beveled edge looks custom and expensive.22

Conclusion=

Understanding the beveling vs. edging difference is simple. Both are high-quality finishes, but they serve different roles. Edging is the functional, necessary process of finishing the thin edge profile for safety and durability. Beveling is the optional, decorative process of cutting an angled surface on the face of the glass to add style and refract light. By assessing your project's style, function, and budget, you can now confidently choose the perfect finish to elevate your glass design.