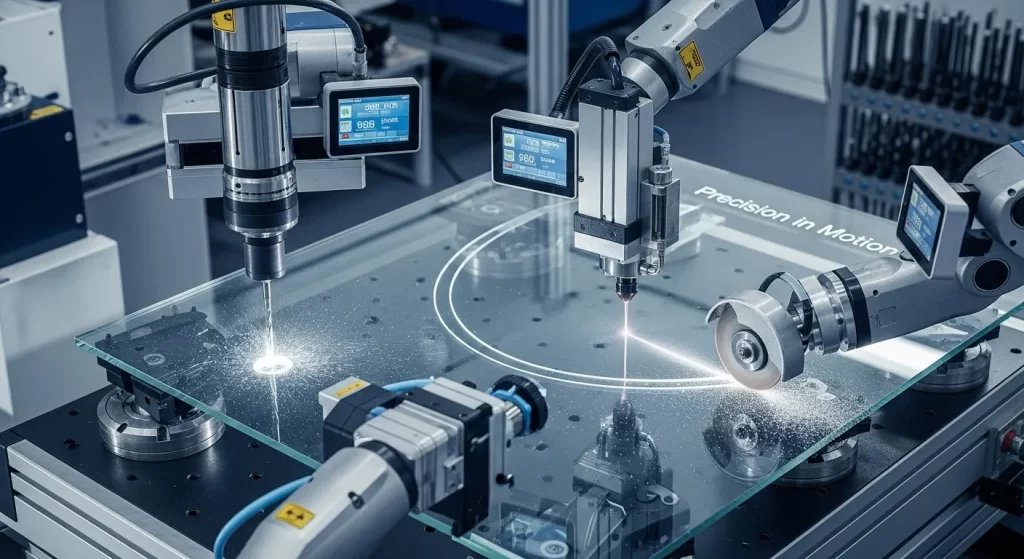

Precision in Motion: Drilling, Cutting, and Grinding Glass the Smart Way

Achieving precision in motion is the defining goal of modern glass fabrication. Glass is a beautiful and versatile material, but it is also notoriously brittle and unforgiving. A minor error in cutting, a misplaced hole, or an inconsistent edge can ruin an expensive piece of material. The "smart way" to handle glass is to move beyond manual methods. It involves using automated, computer-controlled systems to drill, cut, and grind. These systems ensure every action is executed with perfect accuracy and repeatability.

This definitive guide explores the core of this smart approach. We will examine the technologies that make precision possible, from CNC controllers to diamond tooling. We will take a deep dive into the modern processes for cutting, drilling, and polishing. Finally, we will cover the transformative benefits of adopting these methods. This is your expert guide to understanding how modern fabrication achieves flawless results through precision in motion.

What is "Precision in Motion" in Glass Fabrication?

"Precision in motion" refers to the use of automated, computer-controlled technology to manage the glass fabrication process. This includes CNC (Computer Numerical Control) machines, lasers, and robotics. These systems execute tasks with extreme accuracy, ensuring consistent, repeatable results in cutting, drilling, and grinding that manual methods cannot match.

Working with glass is a high-stakes operation. Manual methods, which rely on human skill, are prone to small errors, variations, and breakage. Smart fabrication removes that variability. A digital design is sent directly to a machine. The machine then performs the physical work, following the instructions with a level of precision measured in micrometers.

This technological leap is the difference between craft and industrial-scale production. It is not just about moving faster; it is about moving perfectly, every single time. This concept of Accuracy and precision is the cornerstone of modern quality control. It allows for the creation of complex architectural glass, flawless frameless shower doors, and intricate automotive parts. This entire automated workflow is a key part of any modern glass processing-machine-overview.

What are the Core Technologies Driving Precision? (The "Smart Way")

The core technologies are Computer Numerical Control (CNC) systems acting as the brain, advanced diamond tooling as the hands, and powerful CAD/CAM software for design and instruction. Laser technology also plays a key role as a high-precision, non-contact tool.

These technologies work together to create an automated system. The software creates the plan. The CNC controller translates that plan into movement. The diamond or laser tool executes the plan on the glass.

How Do CNC (Computer Numerical Control) Systems Work?

A CNC system is the "brain" of the machine. It reads a digital design file (G-code) and translates it into precise electrical signals. These signals control servo motors, guiding the cutting, drilling, or grinding tool perfectly along the programmed path.

At its heart, a CNC controller is a high-speed motion computer. It takes a complex design and breaks it down into thousands of tiny, precise movements. It tells the X-axis motor, Y-axis motor, and Z-axis motor exactly where to go and when. In a high-quality system, this is a "closed-loop" process. Encoders on the motors send feedback to the controller. This confirms that the tool has moved to the exact position commanded. This constant feedback loop ensures extreme accuracy. It is the key to improving production with automatic glass machines.

What is the Role of Advanced Diamond Tooling?

Diamond tooling is essential because diamond is one of the few materials hard enough to cut and grind glass effectively. These tools are not simple bits. They are engineered with specific diamond grits, shapes, and bond materials for each task.

Glass is incredibly abrasive. It will destroy ordinary tools. Diamond tools are designed for this challenge.

- Diamond Core Drills: These are hollow tubes with diamond particles bonded to the tip. They grind an "annulus," or ring, to create a hole. This is a clean, low-stress method.

- Diamond Milling Bits: These look like router bits. They are designed to cut sideways as well as downwards, allowing the machine to create shapes.

- Diamond Grinding Wheels: These are larger wheels used for shaping the edge of the glass. They use coarse diamond grits (metal-bond) to remove material quickly.

- Diamond Fining Wheels: These resin-bond wheels use finer diamond grits. They smooth the edge after grinding, preparing it for polishing.

Knowing how to care for these tools is a critical skill. Our guide on how to extend life of glass grinding tools explains this in detail.

How is Laser Technology Used?

Lasers are used as a non-contact "smart" tool for cutting glass. The process, called thermal separation, uses a precise laser beam to heat the glass. This is followed by a jet of cooling air or mist, creating a controlled thermal shock. This results in a perfect, stress-free fracture.

This method is a key part of the glass cutting laser vs traditional cutting discussion. The primary benefit of laser cutting is the edge quality. It produces a "fire-polished" edge that is perfectly smooth and requires no secondary finishing. It is an extremely precise method, ideal for cutting intricate shapes or processing very thin glass for electronics.

Why is Advanced Software (CAD/CAM) Essential?

CAD (Computer-Aided Design) software is used to create the digital blueprint of the part. CAM (Computer-Aided Manufacturing) software is the vital link that translates this blueprint into G-code. It plans the toolpaths, selects the tools, and sets the speeds for the machine.

This software partnership is what makes "precision in motion" possible.

- CAD: The designer draws the final product. This could be an architectural panel or a simple shower door.

- CAM: The CAM programmer takes this drawing and plans the entire manufacturing process. They decide which tool to use for a hole. They determine the path for a milled cutout. They optimize the cutting path for multiple parts on one sheet (called "nesting") to minimize waste.

Without this smart software, a CNC machine would be useless. It needs the detailed, step-by-step instructions that only CAM software can provide.

A Deep Dive: Precision in Glass Cutting

Precision in glass cutting involves using automated systems, like CNC tables or lasers, to achieve perfectly accurate cuts and shapes. This "smart" approach minimizes material waste, ensures part consistency, and produces cleaner edges than traditional manual cutting methods.

Cutting is the first step in fabrication. Getting it right is critical. An error at this stage can be incredibly costly, as a large sheet of glass may be ruined.

How Do CNC Cutting Tables Work? (Score-and-Break)

A CNC cutting table automates the traditional "score-and-break" method. A computer guides a small carbide wheel to create a precise score line. Then, an integrated breakout bar or system applies mechanical pressure to snap the glass perfectly along that line.

This is the workhorse method for cutting large sheets of flat glass for windows and architecture. The CNC gantry moves the cutting head at very high speeds. The nesting software ensures the part layout is optimized for maximum material yield. These machines are the subject of our guide on the best glass cutting machine CNC models. This automated score-and-break method is fast, reliable, and highly efficient for straight-line cuts.

What is the Process for Laser Cutting?

The laser cutting process uses no physical contact. A high-intensity laser beam rapidly heats the glass in a precise line. This is followed immediately by a jet of cooling air or liquid. This controlled thermal shock creates a perfect, stress-free fracture that separates the glass.

This thermal separation method is a key topic in laser glass cutting vs mechanical methods. Its primary benefit is the resulting edge. It is perfectly smooth, strong, and polished. This can eliminate the need for an entire secondary processing step (grinding and polishing). This makes it a very "smart" and efficient process for parts where the edge is visible.

A Deep Dive: Precision in Glass Drilling and Milling

Precision in drilling and milling is achieved using dedicated CNC machines. These machines use high-speed, water-cooled diamond tools to create perfectly placed, chip-free holes (drilling) or complex internal cutouts and shapes (milling) with extreme accuracy and repeatability.

This is an area where smart, automated machines truly shine. Manually drilling glass is a slow, high-risk process. CNC automation makes it a reliable and precise industrial operation.

How Do CNC Drilling Machines Create Perfect Holes?

CNC drilling machines use diamond-tipped core drills. The CNC controller positions the drill precisely. A high-speed spindle, combined with a continuous flow of coolant through the drill, grinds the glass cleanly. This prevents cracks and chips from forming.

A core drill is hollow. It cuts a ring of glass, leaving a solid "slug" in the middle. This reduces stress on the material. The constant flow of water is the most critical part. It serves two purposes:

- Cooling: Prevents thermal shock, which would shatter the glass.

- Flushing: Washes away the fine glass powder, so the drill can continue to cut efficiently.

The consistency of this automated process is one of the main automatic glass drilling machine benefits.

What is the Advantage of Vertical Drilling Machines?

Vertical drilling machines save valuable factory floor space by holding the glass upright. Their main advantage is often a dual-head, counter-drilling system. Two drills engage both sides of the glass at the same time, eliminating "breakout" or chipping on the exit side.

This is a very smart design for high-volume production, such as for frameless shower doors. The "breakout" chip on the back of a hole is a common quality problem. By drilling from both sides to meet in the middle, this problem is completely solved. This technology is explained in depth in our article vertical glass drilling machine explained.

What is CNC Glass Milling? (Beyond Holes)

CNC glass milling uses rotating diamond end mills to cut in multiple directions (X, Y, and Z axes). This allows the machine to create complex shapes inside the glass, such as cutouts for electrical outlets, hardware notches, or decorative patterns.

This is where the true power of a CNC drilling and milling machine for glass is most evident. It is not just a drill press. This operation is almost impossible to achieve with manual tools.

A Deep Dive: Precision in Glass Grinding and Polishing

Precision in grinding and polishing uses automated machinery to shape and finish the raw, sharp edge left after cutting. This multi-stage process creates a safe, smooth, and aesthetically perfect edge, such as a "flat polish" or "pencil polish."

The edge of the glass is a critical part of the final product. A poorly finished edge is a sign of low quality. An automated, "smart" process ensures a perfect finish every time.

What is the Role of a CNC Glass Edge Grinder?

A CNC glass edge grinder uses a series of diamond wheels to automatically shape the edge of a custom-cut piece of glass. It can follow complex curves precisely, something a manual or straight-line machine cannot do, ensuring a uniform edge profile.

Imagine trying to create a perfect, rounded edge on a custom, kidney-shaped tabletop by hand. It is incredibly difficult. A CNC grinder, using the same digital file that was used to cut the glass, follows that path perfectly. It uses a series of wheels to grind and shape the edge. This is a far cry from the basic techniques described in how to use glass edge grinder properly for simple hobbyist work.

How is a Flawless Polish Achieved Automatically?

A flawless polish is achieved in a multi-step sequence on an automated machine. After grinding wheels shape the edge, finer "fining" wheels (resin-bond) smooth it. Finally, polishing wheels (made of felt or composite) use a cerium oxide slurry to create a brilliant, crystal-clear shine.

This sequential process is the key. You cannot go from a rough, cut edge to a high-gloss polish in one step. Each wheel must be finer than the last, systematically removing the scratches from the previous wheel. The final polish is a chemo-mechanical process. The cerium oxide performs a chemical reaction with the glass. The felt wheel buffs it to a high shine. This is the technology inside an industrial glass polishing machine.

What Are the Different Finished Edge Profiles?

Common profiles include "flat polish" (a clean, 90-degree edge, popular for modern glass), "pencil polish" (a soft, rounded C-shape), and "bevel" (an angled cut on the face of the glass, which is a related but separate process).

Smart machines can be tooled to create any edge profile required. The most common include:

- Seamed Edge: The most basic finish. The sharp corners are just sanded off for safety.

- Flat Polish: The most popular modern edge. The edge is perfectly flat and the corners are chamfered.

- Pencil Polish: A soft, C-shaped rounded edge.

- Beveled Edge: A decorative, angled cut on the face of the glass.

- Ogee Edge: A decorative, S-shaped curve used on thick glass.

What Are the Benefits of Adopting These Smart Methods?

The primary benefits are a dramatic reduction in material waste, a massive increase in production speed and repeatability, superior and consistent product quality, and significantly improved operator safety by automating hazardous manual tasks.

The case for adopting these "precision in motion" technologies is overwhelming. The return on investment is found in four key areas.

How Does Precision Reduce Material Waste?

Precision reduces waste by virtually eliminating human error. Automated cutting software optimizes part layouts ("nesting") to get the most pieces from a single sheet. Accurate processing prevents costly mistakes, breakages, and rejected parts.

A single sheet of architectural, low-iron, or specialty glass can cost thousands of dollars. One mis-cut or a misplaced hole can scrap the entire piece. Automated systems do not make these mistakes. Nesting software alone can often improve material yield by 10-15%. This is a direct saving to the bottom line.

How Does Automation Increase Production Speed?

Automated machines operate much faster than manual technicians, 24/7, without fatigue. Features like automatic tool changers eliminate setup time between operations, allowing a single machine to drill, mill, and polish in one continuous cycle.

This is a core part of improving production with automatic glass machines. A manual operator might take 30 minutes to drill and countersink a hole. A CNC machine can do it in 30 seconds. This massive increase in throughput allows a shop to take on more work and deliver products faster.

What is the Impact on Product Quality and Consistency?

The impact is transformative. Every piece is identical. Every hole is perfectly placed, and every edge is perfectly polished. This consistency is the hallmark of professional-grade fabrication, crucial for architectural and high-end consumer products.

When you are installing a 100-panel glass wall, "almost" the same is not good enough. Every panel must be identical for the system to align. Automated processing guarantees this consistency. It moves glass fabrication into the realm of high-precision manufacturing.

How is Operator Safety Improved?

Automation improves safety by moving the operator away from the "point of contact." Machines handle heavy lifting, manage sharp edges, and contain the wet, abrasive slurry. This reduces the risk of cuts, musculoskeletal injuries, and respiratory issues.

Manually working with glass is hazardous. There is a high risk of deep cuts from sharp edges. Handling large, heavy sheets causes back and shoulder injuries. The fine silica dust from dry grinding is a serious respiratory hazard. Smart, automated machines, which are almost always a wet process, contain these dangers. This is a key focus of our guide on safety tips for glass cutting and grinding.

How to Implement Precision Glass Processing

Successful implementation involves a strategic approach. It starts with choosing the right machine for your specific products, committing to a rigorous maintenance schedule to protect the investment, and providing thorough training for operators.

Buying a big, expensive machine is not a magic bullet. It must be integrated into a smart workflow to be effective.

What Are the Key Considerations for Choosing a Machine?

Key considerations include your primary products (high-volume vs. custom-shape), the glass sizes you handle, your budget, the software's ease of use, and the manufacturer's reputation for service and support.

The "best" machine is different for every shop.

- A company making thousands of identical shower doors needs a high-speed vertical glass drilling machine.

- A custom shop making unique art pieces needs a flexible 5-axis CNC drilling and milling machine for glass.

- A shop cutting complex shapes from thin glass might invest in a laser cutting machine. A full analysis of your product line and business goals is essential before buying.

Why is Machine Maintenance So Critical?

Maintenance is critical because glass fabrication is a harsh, abrasive process. The "slurry" (a mix of glass powder and water) is extremely aggressive. It can destroy bearings, guide rails, and other precision components if not managed properly.

A proactive glass grinding machine maintenance schedule is not optional. It is essential for survival. This includes:

- Daily cleaning to remove all slurry.

- Regular lubrication of all motion components.

- Meticulous management of the coolant filtration system. A machine that is not maintained will lose its precision and fail, resulting in a very expensive repair.

How Important is Operator Training?

Operator training is extremely important. A "smart" machine is only as smart as its operator. Technicians must be trained in CAD/CAM software, machine setup, tooling selection, and how to recognize and troubleshoot problems before they cause damage.

A skilled operator can optimize a program to run 20% faster. They can choose the right tool to get a better finish. They can hear a strange noise and stop the machine before a $10,000 spindle is destroyed. The investment in high-quality training for your team is just as important as the investment in the machine itself.

Conclusion

Precision in motion is the new standard for the glass fabrication industry. The "smart" approach, powered by CNC, advanced software, and precision tooling, has moved the industry forward. It has left the old risks and inconsistencies of manual work behind. These automated systems are the key to improving production with automatic glass machines. They deliver a product that is not only made faster and more safely, but is also fundamentally better. For any business that works with glass, embracing this technology is not just an upgrade; it is the path to a high-quality, efficient, and profitable future.