CNC Glass Edging vs. Grinding: The Definitive Guide (2025)

In the world of glass fabrication, precision is paramount. The terms "edging" and "grinding" are often thrown around interchangeably, both by newcomers and even some seasoned professionals. This common confusion can lead to costly mistakes, incorrect job specifications, and products that don't meet aesthetic expectations. I once had a client for a high-end architectural project who specified a "fine ground edge" for a series of large glass panels. They wanted to save costs. What they got was a safe, shaped edge that was milky and opaque—technically what they asked for, but visually unacceptable for the final installation. We had to re-run the entire job with a full polish, a costly lesson in terminology.

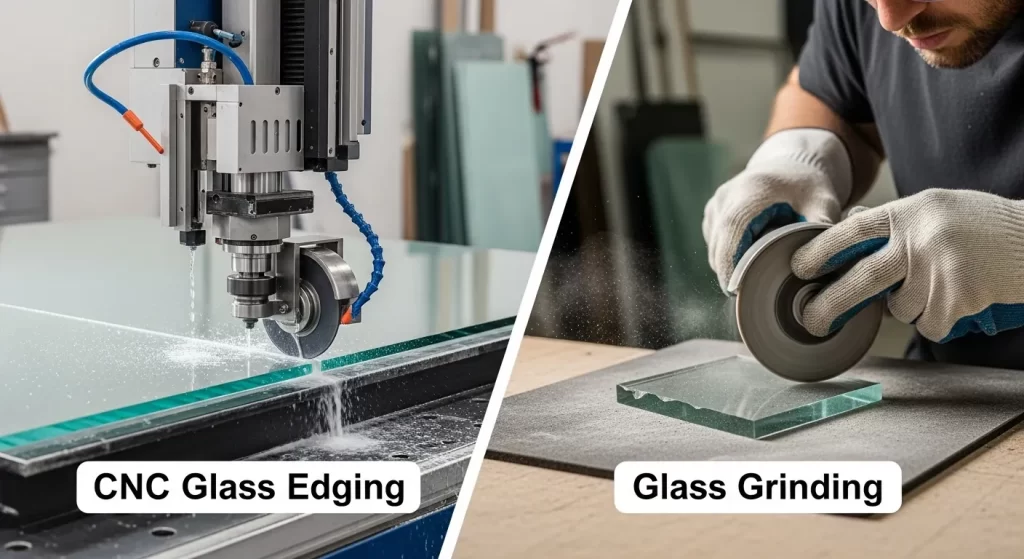

The truth is, while CNC glass grinding and CNC glass edging are intimately related, they are not the same thing. One is a crucial step, while the other is the complete process. Understanding this distinction is fundamental for anyone working with glass, from designers and architects to machine operators and workshop owners.

This definitive guide will eliminate the ambiguity. We will break down the precise role of each process, the tools they use, their specific goals, and the final outcomes they produce. By the end, you'll understand not just the difference, but how to specify the exact finish you need to achieve the perfect balance of safety, function, and beauty.

What is the Core Difference Between CNC Glass Edging and Grinding?

The core difference is that CNC glass grinding is the initial, aggressive stage that uses coarse diamond tools to shape the edge and remove sharp material for safety. In contrast, CNC glass edging is the complete, multi-stage process that includes grinding and then refines and polishes that edge to a desired final aesthetic finish, from a simple satin sheen to a brilliant, transparent polish.

Think of it as finishing a piece of wood. Grinding is the first step: using rough, 80-grit sandpaper to shape the edge and remove splinters. It's functional but leaves a rough surface. Edging is the entire workflow: sanding with 80-grit, then 120-grit, then 220-grit, and finally buffing with a fine cloth to achieve a perfectly smooth, finished surface. Grinding is a foundational action; edging is the complete journey to a final, specified result.

What is CNC Glass Grinding in Detail?

CNC glass grinding is the subtractive machining stage that uses coarse-grit, metal-bonded diamond wheels to shape a raw, freshly cut glass edge. Its primary goals are to remove the hazardous sharp arrises (the sharp corners of the edge), create a specific profile like a flat or pencil shape, and prepare the glass for further finishing stages. It prioritizes safety and form over aesthetics.

When glass is cut, the edge is incredibly sharp and filled with microscopic flaws, making it fragile and dangerous to handle.1 Grinding is the first-line solution.

- The Goal: Safety and Shaping. The number one goal is to make the glass safe to handle. The secondary goal is to machine the edge into a specific shape. This could be creating a perfectly flat 90-degree edge or rounding it into a C-shape.

- The Tools: Metal-Bonded Diamond Wheels. Grinding requires aggressive material removal.2 This is achieved with wheels where diamond particles are held in a hard metal matrix. These tools are durable and can withstand the high pressure needed to grind glass efficiently. The grit size is typically coarse, often in the 80 to 120 range.

- The Process. A modern CNC glass working center uses a pre-programmed path to move the rotating grinding wheel along the perimeter of the glass. A constant flow of coolant is essential to prevent thermal shock and wash away glass dust.3 This entire automated workflow is a core aspect of how CNC glass machines work.

- The Outcome. The result of the grinding stage is a shaped edge that is safe to touch. However, the finish is opaque, rough, and has a "milky" or "cloudy" appearance due to the millions of small fractures created by the coarse diamonds. It is not a decorative finish.

What Defines the CNC Glass Edging Process?

CNC glass edging is a comprehensive, multi-stage process that begins with grinding and is then followed by one or more stages of fining (honing) and polishing.4 It uses a sequence of progressively finer-grit wheels to systematically transform a rough, ground edge into a smooth, aesthetically pleasing final finish, such as a satin or brilliant diamond polish.

Edging is the art and science of creating the final beautiful edge. It's where the value is added.

- The Goal: Aesthetics and Final Finish. While safety is a given, the primary goal of edging is to produce a specific visual and tactile quality. This could be a frosted satin finish or a perfectly transparent, glossy edge that sparkles as it catches the light.

- The Tools: A Sequential Set of Wheels. The edging process requires a tool change sequence, a key feature of modern CNC automation in glass processing.

- Grinding Wheel (Metal-Bond): The first step, as described above.

- Fining/Honing Wheels (Resin-Bond): These wheels use finer diamond grits (e.g., 200-400 grit) held in a softer resin bond. They remove the deep scratches left by the grinding wheel and smooth the surface.

- Polishing Wheels (Felt or Rubber): The final step. These wheels typically have no diamonds. Instead, they are used with a slurry of cerium oxide, a fine powder that creates a chemical-mechanical reaction with the glass to produce a brilliant, high-gloss shine. This is detailed in our guide to CNC glass polishing techniques.

- The Outcome. The result is a fully finished edge that meets aesthetic specifications. The most common polished edges are "Flat Polish" and "Pencil Polish." Decorative edges, like those created by a CNC glass beveling machine, are also a form of specialized edging.

Head-to-Head Comparison: CNC Grinding vs. Edging

To make the distinction crystal clear, here is a direct comparison of the two processes across several key attributes. Understanding this table is crucial when deciding how to choose a CNC glass machine for your workshop, as you need to ensure it has the capabilities for the full edging process if required.

| Feature | CNC Glass Grinding | CNC Glass Edging |

| Stage of Process | The initial step of shaping the edge. | The complete process, from start to finish. |

| Primary Goal | Safety, shaping, removing sharp arrises. | Final aesthetics, achieving a specific look & feel. |

| Tools Used | Coarse-grit, metal-bonded diamond wheels. | A sequence of wheels: grinding, fining, and polishing. |

| Resulting Finish | Opaque, rough, milky, semi-transparent. | Smooth, transparent, satin, or brilliant polish. |

| Process Nature | A single-stage, aggressive action. | A multi-stage, progressively finer process. |

| When It's Used | On every piece of glass that is handled. | On pieces where the edge will be visible and requires a finish. |

| Final Step? | Rarely. Only for completely hidden applications. | Yes. This process produces the final product. |

When is a Ground Edge Sufficient?

A ground edge is sufficient only when the glass edge will be completely hidden from view in the final installation and aesthetics are entirely irrelevant. The only requirements in these cases are safety during handling and a specific shape to fit into a frame or channel.

This is a critical cost-saving consideration. Performing the extra steps of fining and polishing takes machine time, which costs money. According to a Glass Processing Industry analysis, skipping polishing can reduce machine time per part by up to 60%.

Here are practical examples where a ground-only edge is acceptable:

- Insulated Glass Units (IGUs): The edges of the glass panes in a double-glazed window are sealed inside the unit and are never seen.5

- Framed Glass: When glass is installed into a deep U-channel or a picture frame that completely covers the edge.

- Industrial Applications: Glass components inside machinery or equipment where the edge is purely functional.

- Backsplashes with Trim: If a decorative metal or tile trim will be covering the perimeter of a kitchen backsplash, a full polish is unnecessary.

Specifying "grind and arriss" instead of "flat polish" can lead to significant savings on large orders.

How Do Tooling and Machine Settings Differ?

The tooling and machine settings for grinding versus the polishing stage of edging are fundamentally different, as they are designed for opposite goals: aggressive material removal versus delicate surface refinement.6 Using the wrong parameters can ruin the finish or damage the tool.

Tooling Differences

- Grinding Wheels: Use a metal bond to hold coarse diamond grits (e.g., 100-grit). The hard metal bond exposes new diamond edges as it slowly wears away, making it ideal for high-pressure shaping.7

- Polishing Wheels: Use a very hard, compressed felt or synthetic rubber material. These wheels, like the commonly used "BK" wheels, don't cut the glass. They work with a cerium oxide slurry to create a chemical reaction that polishes the surface to a brilliant shine. The quality of the final polish is directly tied to the quality of the cerium oxide.8

Machine Setting Differences

- Spindle Speed (RPM): Grinding wheels often operate at a different optimal RPM than polishing wheels to prevent overheating and ensure a clean cut.

- Feed Rate (Travel Speed): The feed rate for grinding can be relatively fast. For polishing, the feed rate is typically much slower. This gives the polishing wheel and cerium slurry enough time to work on the surface and generate the high-gloss finish. Rushing the polishing stage is a common mistake that leads to a hazy, unfinished look.

- Tool Pressure: A CNC machine can control the downward pressure of the tool.9 Grinding requires higher pressure to remove material, while polishing requires lighter, consistent pressure to avoid burning the edge or wearing out the wheel prematurely. Proper maintenance for CNC glass machinery includes calibrating these pressure settings regularly.

Conclusion: Precision in Language and Fabrication

In the world of Computer Numerical Control, precision begins with language. The difference between CNC glass edging and grinding is not mere semantics—it's the critical distinction between a rough, intermediate step and a beautiful, finished product.

To recap the essential takeaway:

- Grinding is the foundational action of shaping the edge for safety. It's a process defined by coarse tools and a functional, non-aesthetic finish.

- Edging is the complete journey. It starts with grinding, progresses through fining, and culminates in a specific aesthetic polish.

By understanding and using these terms correctly, you empower yourself to specify jobs accurately, control costs effectively, and ensure the final product aligns perfectly with your vision. This knowledge is the true edge in achieving excellence in glass fabrication.