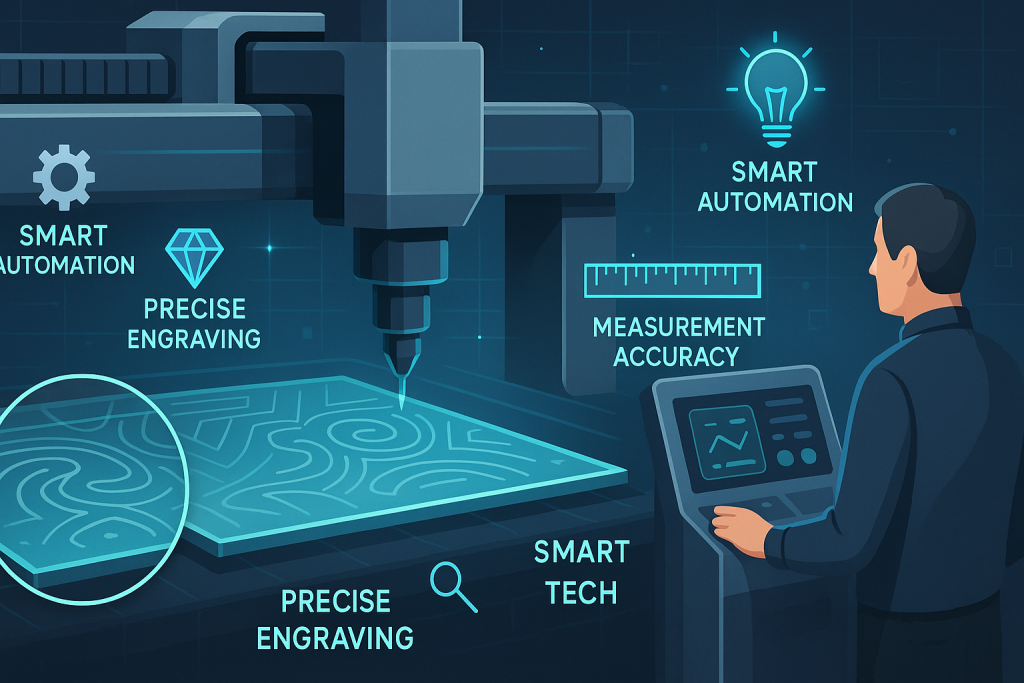

Berlin CNC Glass Engraving Machine – Smart CNC Tech

A Berlin CNC glass engraving machine with smart CNC tech represents the next evolution in glass processing. This advanced manufacturing equipment integrates principles of Industry 4.0, combining precision mechanics with intelligent software, data connectivity, and automation. These machines are designed not just to execute commands, but to optimize their own performance, reduce errors, and provide operators with unprecedented levels of control and insight. For businesses in the architectural, automotive, and high-tech sectors, a Berlin CNC glass engraving machine is more than a tool. It is a strategic asset for building a more efficient, productive, and future-proof manufacturing operation.

The Core of Smart CNC Technology

"Smart" technology in the context of a CNC machine refers to a suite of features that go beyond simple automation. It involves the integration of sensors, data processing, and connectivity to create a machine that is more aware, more efficient, and easier to manage. This is a fundamental shift from a machine that just follows instructions to one that actively participates in the production process.

Beyond Automation: Data and Connectivity

Traditional CNC is about automation. Smart CNC is about automation plus intelligence. A smart machine is equipped with numerous sensors that constantly collect data on its performance. This can include data on motor temperature, spindle load, and vibration levels. This data is processed in real-time by the machine's powerful controller. Furthermore, the machine is connected to the company's network. This allows production data to be shared and enables remote monitoring and diagnostics.

The Importance of a Powerful Modern Controller

The brain of a smart machine is its CNC controller. A modern controller is a powerful industrial computer. It can process complex programs with millions of lines of code at very high speeds. It also runs the software that enables the machine's smart features. This includes an intuitive, graphical user interface that makes the machine easier to operate. The controller is the central hub for all the machine's data and communication.

How Intelligent Software Drives Smart Operations

The software on a smart machine is a key differentiator. It does more than just generate toolpaths. It can include modules for:

- Process Simulation: A complete virtual simulation of the engraving process to detect errors before they happen.

- Tool Management: A database that keeps track of every tool, its usage, and its remaining life.

- Production Scheduling: Software that can integrate with a company's ERP system to manage the workflow.

- Energy Management: Features that monitor and optimize the machine's energy consumption. This intelligent software is what turns a powerful machine into a truly smart manufacturing solution. The overall focus on smart manufacturing is a key trend across the entire germany cnc glass engraving machine market.

Key Smart Features and Their Impact

A Berlin CNC glass engraving machine is defined by a set of smart features. These are practical technologies that deliver tangible benefits in terms of efficiency, quality, and reliability. They are designed to reduce the burden on the operator and to make the entire manufacturing process more robust and predictable.

Table: Key Features of Smart CNC Tech for Glass Engraving

| Smart Feature | Description | Benefit for the User |

| Predictive Maintenance | Sensors monitor component health and predict potential failures. | Reduces unplanned downtime; allows for scheduled maintenance. |

| Automated Calibration | Laser or touch probes automatically measure tools and the workpiece. | Eliminates manual setup errors; improves accuracy and consistency. |

| Remote Monitoring | Machine status and production data can be viewed on a PC or mobile device. | Allows managers to track progress from anywhere; enables faster support. |

| Adaptive Control | The machine adjusts cutting speeds in real-time based on spindle load. | Optimizes cutting performance; prevents tool breakage and improves finish. |

| Energy Saving Modes | The machine automatically powers down non-essential systems when idle. | Reduces electricity consumption and lowers operating costs. |

Predictive Maintenance and Diagnostics

This is a core feature of a smart machine. Instead of waiting for a component to fail, the machine's sensors can detect early warning signs. For example, it can detect a slight increase in a motor's temperature or a new vibration pattern. The system can then alert the operator that a component may need service soon. This allows maintenance to be scheduled at a convenient time, preventing costly, unexpected breakdowns during production.

Automated Setup and Calibration

Setting up a job on a traditional CNC machine can be a time-consuming and skill-intensive process. Smart features automate many of these tasks. A laser probe can automatically measure the length and diameter of each engraving tool with micron-level accuracy. A touch probe can be used to automatically find the exact position of the glass sheet on the table. This automation reduces setup times and eliminates a major source of human error.

Applications in Modern Manufacturing and Design

The smart features of a Berlin CNC glass engraving machine make it particularly well-suited for demanding, high-volume, and high-value applications. It is a tool for industries where efficiency, traceability, and quality are paramount.

High-Volume Production of Architectural Glass

In the production of architectural glass for large projects, consistency is key. A smart machine can ensure that hundreds of glass panels are engraved with a perfectly identical pattern. The machine's monitoring capabilities can provide a quality report for every piece produced. This traceability is valuable for large construction projects. The final products are a form of modern Engraved glass.

The Automotive Industry: Traceability and Customization

The automotive industry relies heavily on data and traceability. A smart CNC machine can engrave a unique serial number or QR code on every piece of glass it produces. This data can be automatically logged in a production database. This is critical for quality control and recalls. The technology is also used for the high-end customization of interior glass components. This level of smart manufacturing is a focus for other major automotive hubs, including those served by the munich cnc glass engraving machine market.

The Electronics and Technical Glass Sector

In the production of glass for electronic displays or technical instruments, precision is absolute. Smart features like adaptive control and automated calibration are essential for this work. They ensure that every engraving is performed with the highest possible level of accuracy and consistency. The machine's ability to monitor its own performance in real-time is crucial for these zero-failure applications.

Sourcing a Berlin CNC Glass Engraving Machine

Acquiring a smart CNC machine is a strategic decision. It requires a partnership with a supplier that is a leader in technology and can provide the high level of support that this advanced equipment demands.

Identifying Suppliers at the Forefront of Smart Technology

Look for suppliers and manufacturers who are actively promoting and developing Industry 4.0 features. They should be able to clearly articulate the benefits of their smart technology. Their product literature and technical specifications should detail the connectivity, data, and automation features of their machines. These are the technology leaders in the field.

The Importance of Software Training and Integration

With a smart machine, the software is as important as the hardware. The supplier must provide in-depth training on all aspects of the software. They should also be able to provide support for integrating the machine with your company's existing network and production management systems. This integration is key to unlocking the full potential of a connected machine. This is a common requirement when dealing with advanced suppliers, such as a paris cnc glass engraving machine provider.

Evaluating the Total Value Proposition

A smart machine may have a higher initial purchase price than a standard machine. However, it is important to evaluate the total value proposition. The benefits of reduced downtime, lower error rates, and increased efficiency can lead to a very rapid return on investment. A smart machine is an investment in higher productivity and lower long-term operating costs. This is a key consideration for businesses in neighboring markets as well, such as for the warsaw cnc glass engraving machine.

Operating a Smart CNC Engraving System

The role of the operator changes with a smart machine. The focus shifts from manual intervention to process monitoring and management.

The Shift from Manual Operation to Process Management

On a traditional machine, the operator is constantly making manual adjustments. On a smart machine, many of these adjustments are made automatically. The operator's role becomes more strategic. They are responsible for setting up the job, managing the production schedule, and monitoring the data the machine is providing. It is a more skilled and less labor-intensive role.

Leveraging Data for Process Optimization

A smart machine produces a wealth of data. A savvy operation will use this data to continuously improve its processes. By analyzing production times, tool life data, and error reports, you can identify areas for optimization. This data-driven approach to process improvement is a core principle of modern manufacturing. This is a focus for advanced manufacturers in many regions, including those using the prague cnc glass engraving machine.

Conclusion

The Berlin CNC glass engraving machine with smart CNC tech is a powerful tool for the future of manufacturing. It represents a significant leap forward in efficiency, reliability, and control. By integrating intelligent features like predictive maintenance, automated calibration, and remote monitoring, these machines empower businesses to operate at a higher level. They reduce errors, minimize downtime, and provide the data needed for continuous improvement. For any company in the glass industry looking to gain a decisive competitive advantage, an investment in this smart technology is an investment in a more productive and profitable future.