7 Core Benefits of a CNC Glass Beveling Machine Revealed (2025)

There’s a certain magic to a perfectly beveled piece of glass. The way it catches the light, the clean, angled edges that create a prism effect—it transforms a simple mirror or tabletop into a piece of art. For years, achieving this look, especially on custom shapes, was the exclusive domain of master craftsmen. I remember early in my career watching a veteran artisan spend the better part of a day manually grinding and polishing a complex bevel on an oval mirror. His skill was undeniable, but the process was slow, physically demanding, and one slip of the hand could ruin the entire piece.

Fast forward to today. I recently programmed a 5-axis CNC (Computer Numerical Control) machine to do a job that would have made that old-timer’s head spin: a set of eight interlocking, serpentine-shaped mirrors, each with a perfectly consistent 1-inch bevel. The entire set was completed in a few hours, and every single piece was a flawless, identical twin to the last.

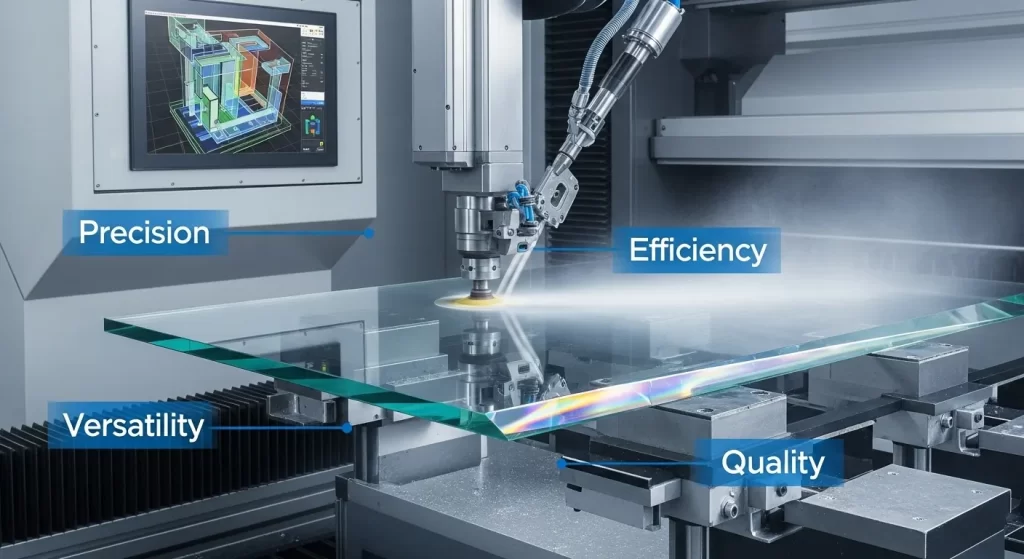

That is the revolutionary power of a CNC glass beveling machine. It’s not just about replacing manual labor; it’s about unlocking a level of precision, creativity, and efficiency that was simply out of reach before. This guide will reveal the core benefits of this technology, moving beyond the technical jargon to show you how it directly translates into superior quality, higher productivity, and a stronger bottom line for any glass workshop.

What Exactly is CNC Glass Beveling?

CNC glass beveling is an automated process where a computer-controlled machine uses a series of diamond-impregnated grinding and polishing wheels to create a precise, angled edge on a piece of glass. Unlike traditional straight-line bevelers, a CNC machine can follow any programmed path, allowing it to create flawless bevels on circles, ovals, and complex custom shapes.

The machine follows a digital design file (CAD), which dictates the exact path, angle, and width of the bevel. An operator secures the glass to the machine bed, and the CNC controller executes the program, automatically moving the glass or the tool head through the sequence of grinding and polishing stations. This high degree of automation is a cornerstone of the modern glass processing industry, ensuring every piece meets exact specifications with minimal human intervention.

Benefit #1: How Does a CNC Machine Achieve Flawless Precision and Consistency?

A CNC machine achieves flawless precision by eliminating human error and relying on computer-controlled movements accurate to fractions of a millimeter. Every parameter—bevel angle, width, and tool path—is dictated by a digital program, ensuring that every single piece produced is an exact identical copy of the first, a feat impossible to replicate manually.

This benefit is the most significant advantage of CNC technology. A human operator, no matter how skilled, will have minute variations in pressure and angle, especially when working on complex curves. A CNC machine does not.

- Digital Accuracy: The machine follows a vector path from a CAD file. This means if you design a perfect circle, the machine will produce a perfect circle. According to industry reports, a well-maintained CNC machine can achieve a dimensional accuracy of ±0.1mm.

- Uniform Angles: The angle of the bevel is set in the program and maintained perfectly throughout the entire process, even around the tightest corners. This prevents the "wavy" or inconsistent look that can plague manually beveled pieces.

- Perfect Mitered Corners: For pieces that need to fit together, like in a multi-panel mirror wall, the ability to create perfectly mitered corners is critical. CNC machines produce clean, sharp corners that align seamlessly.

- Repeatability: Whether you are making one piece or one thousand, the last one will be a perfect mirror image of the first. This level of consistency is crucial for large architectural projects and high-volume production runs. This is explained in more detail in our complete guide on how CNC glass machines work.

Benefit #2: Does a CNC Beveler Offer More Design Freedom?

Yes, a CNC beveling machine offers almost limitless design freedom compared to traditional methods. Because it can follow any programmed path, it can create beautiful, consistent bevels on virtually any shape, from simple circles and ovals to complex free-form designs, unlocking new creative possibilities for architects, designers, and artists.

This is where CNC technology truly shines, turning a workshop into a custom fabrication studio. Before CNC, beveling was largely restricted to straight lines or simple arcs. Now, the only limit is the designer's imagination.

- Internal Bevels: CNC machines can create internal bevels on cutouts within a piece of glass, such as the inside edge of a frame or a complex pass-through. This was incredibly difficult and often impossible with older machinery.

- Complex Curves: Serpentine, S-curves, and other organic shapes can be beveled with the same ease and consistency as a straight line.

- Variable Bevel Widths: Advanced programming allows for the creation of variable-width bevels, where the bevel gracefully transitions from thick to thin along its path, creating a unique and dynamic visual effect.

- Integration with Other Processes: A modern CNC glass working center can combine beveling with other operations like drilling and milling in a single program. Imagine a glass panel with a beveled edge, drilled holes for fittings, and an elegant internal cutout—all done in one seamless operation. A market analysis showed that the demand for custom-shaped decorative glass has grown by over 12% in the last three years, a trend driven almost entirely by CNC capabilities.

Benefit #3: How Does CNC Beveling Dramatically Increase Productivity?

CNC beveling dramatically increases productivity by automating the entire process, reducing manual labor, and enabling a single operator to manage a machine that works faster and more continuously than a team of craftsmen. The ability to run complex jobs overnight or with minimal supervision slashes lead times and boosts workshop output.

Time is money in any fabrication environment. The efficiency gains from a CNC beveler are multifaceted and have a direct impact on profitability.

- Reduced Labor Costs: A single operator can set up the machine and let it run, freeing them up to work on other tasks. This significantly reduces the man-hours required per piece.

- Faster Processing Times: While the feed rate for beveling is carefully controlled, the machine works continuously without breaks or fatigue. For multi-piece jobs, the cumulative time savings are enormous.

- Quick Changeovers: Switching from one design to another is as simple as loading a new program. This agility allows a workshop to handle a wider variety of custom jobs without lengthy setup periods.

- "Lights-Out" Manufacturing: Many robust CNC machines can be loaded with multiple jobs and left to run unattended overnight, effectively doubling a workshop's production capacity without adding a second shift. This level of automation in glass processing is a key competitive advantage.

I once worked with a client who manufactured custom mirrors for hotels. Their team of four craftsmen could produce about 20 complex mirrors per day. After investing in a CNC beveler, a single operator was producing over 50 mirrors per day, and the quality was far more consistent. Their production more than doubled while their labor costs were cut in half.

Benefit #4: What is the Impact of CNC Beveling on Product Quality?

The impact of CNC beveling on product quality is transformative, resulting in a flawless, high-polish finish that is virtually impossible to achieve consistently by hand. The machine's precise control over tool pressure and progression—from coarse grinding to fine polishing—produces a crystal-clear bevel free of scratches, haze, or imperfections.

The final finish is what a customer sees and feels. A high-quality bevel isn’t just about the angle; it’s about the optical clarity and smoothness of the surface.

- Systematic Tool Progression: The machine automatically moves through a sequence of wheels, from coarse-grit diamond wheels for initial grinding to progressively finer resin and felt wheels for polishing. This methodical process ensures a perfect finish every time. You can learn more about this in our guide to CNC glass polishing techniques.

- Consistent Pressure: The CNC controller maintains the exact optimal pressure for each wheel, preventing the tool from digging in too deep (causing marks) or being too light (leaving a hazy finish).

- Elimination of "White Corners": A common issue in manual beveling is "white corners" or "blow-outs," where the corner is not perfectly polished. CNC machines use specific tool paths and specialized wheels to ensure corners are as crystal-clear as the straight edges.

- Increased Perceived Value: A product with a perfect, brilliant bevel commands a higher price. The superior quality is immediately apparent to the end-user, enhancing the perceived value of the mirror, tabletop, or architectural element. Studies have shown that high-quality finishing can increase the retail price of a glass product by as much as 25%.

Benefit #5: Is Using a CNC Beveling Machine Safer?

Yes, using a CNC beveling machine is significantly safer than manual methods. The entire grinding and polishing process takes place within a sealed safety enclosure, protecting the operator from direct contact with the spinning tools, glass dust, and coolant spray. This drastically reduces the risk of cuts, respiratory issues, and other workshop injuries.

Safety should be a top priority in any glass workshop. The hazards of manual glass work are well-known.

- Operator Isolation: The operator's main interaction is with a computer screen and control panel, far from the actual machining process. Safety interlocks prevent the machine from running if the enclosure doors are open.

- Containment of Slurry: The mixture of glass dust and coolant, known as slurry, is contained within the machine and managed by a filtration system. This prevents the inhalation of harmful silica dust, a major occupational hazard.

- Reduced Physical Strain: Manual beveling is physically demanding work, leading to repetitive strain injuries and chronic back issues. CNC automation eliminates this physical burden entirely.

- Less Glass Handling: By combining multiple processes in one setup, the CNC machine reduces the number of times a heavy or awkward piece of glass needs to be manually lifted and moved between different workstations, which is a common source of accidents and breakage.

Benefit #6: How Does CNC Beveling Reduce Material Waste?

CNC beveling reduces material waste by virtually eliminating operator errors that can lead to rejected or broken pieces. The high precision and repeatability mean that every piece is machined correctly the first time, saving not only the cost of the wasted glass but also the time and labor invested in the piece up to that point.

Waste in a glass shop is a direct hit to the bottom line. A single rejected piece of expensive, low-iron glass can wipe out the profit from an entire job.

- Elimination of "Slips": One slip of the hand in a manual process can send a crack through a large piece of glass, rendering it useless. The CNC machine does not slip.

- First-Time-Right Production: The "what you see is what you get" nature of the CAD-to-machine process means there's no guesswork. You can simulate the entire process on the computer before cutting, catching potential errors in the design phase.

- Optimization for Rework: In the rare case of a minor flaw, the CNC machine can be programmed to re-run the polishing stage on a specific area, saving a piece that might otherwise be scrapped.

- Predictable Outcomes: CNCs provide predictable and reliable results, which is crucial for quoting jobs accurately and maintaining profitability. The reduction in scrap rates after implementing CNC technology is often cited as a key driver of ROI. Some workshops report scrap rate reductions of over 75%.

Benefit #7: What is the Long-Term ROI of a CNC Beveling Machine?

The long-term return on investment (ROI) for a CNC beveling machine is excellent, driven by a combination of reduced labor costs, increased production output, lower material waste, and the ability to command higher prices for superior quality and custom designs. While the initial investment is significant, the machine quickly becomes a profit center for the workshop.

Thinking about how to choose a CNC glass machine for your workshop involves a serious financial calculation, but the returns are clear.

- Higher Margins: The ability to produce high-value, custom work allows you to move into more profitable market segments.

- Increased Capacity: Taking on larger, more complex architectural projects becomes feasible.

- Competitive Advantage: Offering a level of quality and design freedom that competitors with older equipment cannot match sets your business apart.

- Lower Operating Costs: Over time, the savings on labor and wasted material accumulate, directly contributing to the machine paying for itself. An ROI calculation should always factor in these long-term savings.

Frequently Asked Questions (FAQ)

Can a CNC machine bevel very thick glass?

Yes, CNC machines are well-suited for beveling thick glass. The machine can be programmed to make multiple, progressively deeper passes to create a wide, clean bevel on glass up to 19mm (3/4 inch) thick or more, a task that is extremely challenging to do manually.

What's the difference between a CNC beveler and a straight-line beveling machine?

A straight-line beveling machine is a specialized piece of equipment that can only produce bevels on straight edges. The glass is fed through a series of wheels in a line. A CNC beveler is a far more versatile machine that can bevel any shape—straight, curved, or custom—because it moves the tool around the glass (or the glass under the tool) based on a computer program.

Does the beveling process weaken the glass?

No, quite the opposite. Properly grinding and polishing the edge of the glass removes the microscopic flaws and sharp points that can lead to fractures. A smoothly beveled or polished edge is significantly stronger and more resistant to chipping than a raw cut edge. This is a fundamental concept in glass fabrication, closely related to the principles of CNC glass edging and grinding.

Conclusion

Investing in a CNC glass beveling machine is about more than just upgrading equipment. It's about fundamentally transforming your workshop's capabilities. It's about saying "yes" to complex, high-value projects you previously had to turn down.

The seven core benefits—precision, design freedom, productivity, quality, safety, waste reduction, and profitability—all point to the same conclusion: CNC technology is the key to staying competitive and thriving in the modern glass fabrication industry. The magic of that perfect, light-catching bevel is no longer the exclusive art of a few; it's a precise, repeatable science that is accessible to any workshop willing to embrace the future.