A Guide to Automatic Glass Drilling Machine Benefits

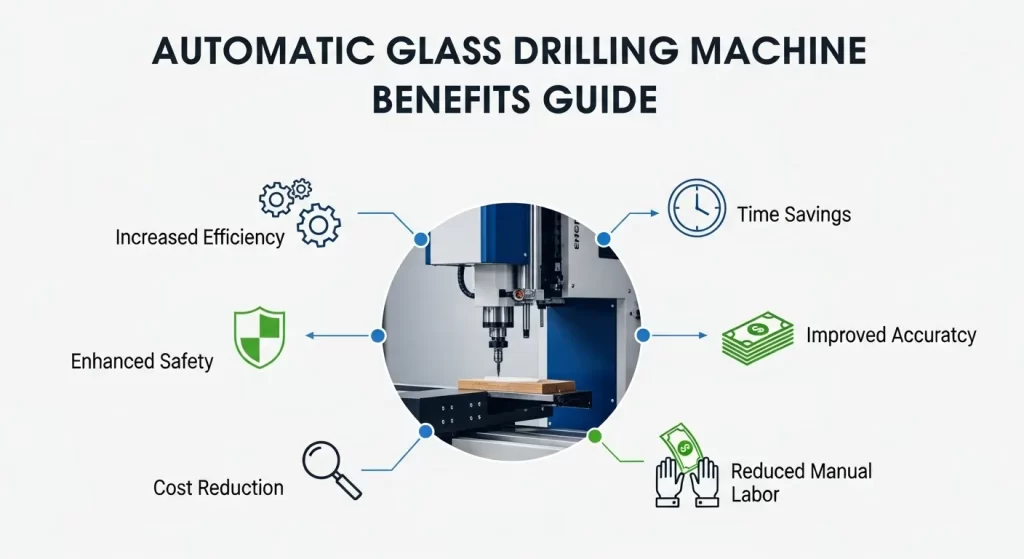

The core automatic glass drilling machine benefits are a transformative combination of unmatched precision, dramatic increases in production speed, and a significantly safer working environment. Investing in this technology is a strategic move for any modern glass fabrication workshop. It replaces the limitations and inconsistencies of manual drilling with the reliability and accuracy of computer control. This guide provides a definitive and expert analysis of these benefits. It details how automation elevates quality, reduces waste, and ultimately drives profitability in the demanding world of glass processing.

What Are the Core Automatic Glass Drilling Machine Benefits?

The core benefits of an automatic glass drilling machine are its exceptional precision and repeatability, a massive increase in production speed, superior hole quality with less waste, and a fundamentally safer operational process. This technology automates a critical and often challenging step in glass fabrication, delivering a powerful return on investment.

These benefits are not isolated advantages. They work together as a system. The precision of the machine leads to higher quality, which in turn reduces material scrap rates. The speed of automation increases throughput, allowing a workshop to take on more work and meet tighter deadlines. The enclosed, automated process removes the operator from the most hazardous aspects of the job. This creates a safer and more efficient production environment.

Benefit 1: How Does Automation Deliver Unmatched Precision?

Automation delivers unmatched precision by replacing the variability of human skill with the infallible accuracy of computer numerical control (CNC). A CNC system can execute a drilling program with tolerances measured in micrometers. It ensures that every hole is perfectly placed, perfectly sized, and identical to the last. This level of precision is simply unattainable with manual or semi-automatic methods.

How Does Automation Eliminate Human Error?

Automation eliminates human error by removing the operator from the direct execution of the drilling task. In a manual process, the accuracy of a hole's position depends entirely on the operator's skill in marking and aligning the glass. This is a slow process that is prone to small but significant errors. An automatic machine reads a digital design file. Its CNC drilling and milling machine for glass controller directs the drill heads to the exact coordinates specified in the program. The machine does not misread a measurement or have an unsteady hand. It executes the program perfectly every single time.

Why is Positional Accuracy Critical for Hardware?

Positional accuracy is absolutely critical for the proper fitment of hardware. Frameless shower doors, glass railings, and architectural panels all rely on precise hole patterns to mount hinges, handles, standoffs, and other fittings. An error of even a single millimeter can prevent a hinge from closing correctly or cause a panel to be misaligned. An automatic machine ensures that the hole pattern is a perfect match to the hardware's specifications. This eliminates costly rework and on-site installation problems. The consistency of automated drilling is a major factor in reducing project delays.

How Does it Ensure Consistent Hole Quality?

An automatic machine ensures consistent hole quality by precisely controlling every parameter of the drilling process. This includes the rotational speed of the drill, the feed rate at which it advances, and the flow of coolant. These parameters are optimized to create a clean, chip-free hole every time. This is in stark contrast to manual drilling, where pressure and speed can vary, leading to inconsistent results. The final hole is not just accurately placed; it is also perfectly round, with smooth internal walls. This improves both the aesthetic and the structural integrity of the final product.

Benefit 2: What is the Impact on Production Speed and Efficiency?

The impact of an automatic glass drilling machine on production speed is transformative. These machines are engineered for high-throughput environments. They incorporate technologies specifically designed to minimize cycle times and reduce non-productive setup time. For a workshop that drills a significant volume of holes, the productivity gains are immediate and substantial. This is a key part of improving production with automatic glass machines.

How Do Dual-Head Systems Double Drilling Speed?

Many advanced automatic drilling machines, particularly vertical models, use a dual-head or counter-drilling system. This technology is a game-changer for speed. The machine has two opposing drill spindles, one on each side of the glass. When a hole is programmed, both drills advance simultaneously and meet in the middle. This technique effectively cuts the drilling time for a single hole in half. For a panel that requires eight holes, this translates to a massive reduction in the total cycle time per piece. A complete overview of this technology is available in our guide where the vertical glass drilling machine is explained.

What is the Impact of Automated Tool Changing?

An Automatic Tool Changer (ATC) is another key efficiency feature. Many jobs require holes of different diameters on the same piece of glass. In a manual process, this would require the operator to stop the machine and manually change the drill bit. An ATC is a carousel or magazine that holds a variety of pre-loaded tools. The machine can automatically switch between these tools as needed, without any operator intervention. This eliminates setup time between different hole sizes and allows for a continuous, uninterrupted production cycle.

How Does it Enable Continuous, High-Volume Operation?

Automatic machines are designed for the rigors of continuous operation. Their robust construction and automated workflows allow them to run for long periods with minimal supervision. In a fully automated production line, a drilling machine can be integrated with loading and unloading systems. This allows for "lights-out" manufacturing, where the machine can continue to process parts overnight. This ability to maximize operational hours is a key driver of profitability in high-volume fabrication. The industrial automation market continues to grow, driven by these productivity benefits.

Benefit 3: How Does Automation Dramatically Improve Safety?

Automation dramatically improves workshop safety by isolating the operator from the most hazardous aspects of the glass drilling process. Manual glass drilling is a high-risk activity. It involves handling sharp glass, working with high-speed rotating tools, and operating in a wet environment. An automatic machine encloses and automates these processes. This creates a fundamentally safer workplace.

How Does Automation Reduce Handling Injuries?

Automation significantly reduces the risk of cuts and strains associated with handling glass. In an automated system, the glass is loaded onto a conveyor and clamped by the machine. The operator does not need to manually hold or position the glass during the drilling process. This minimizes direct contact with potentially sharp edges. The reduction in manual handling of heavy glass sheets also reduces the risk of musculoskeletal injuries. Adherence to best practices is still key, as detailed in our safety tips for glass cutting and grinding.

What is the Role of the Machine Enclosure?

The machine's safety enclosure is a critical protective feature. It is a fully enclosed cabinet that surrounds the entire work area. This enclosure serves two primary safety functions. First, it provides a physical barrier between the operator and the high-speed drill spindles. This prevents any accidental contact with the moving components. Second, it contains all the coolant splash and the fine glass slurry that is created during drilling. This keeps the surrounding floor dry, preventing slip and fall hazards. It also helps to contain the fine glass dust, improving the workshop's air quality.

How Does it Minimize the Risk of Glass Breakage?

An automatic machine minimizes the risk of catastrophic glass failure during drilling. Breakage is most often caused by excessive pressure or thermal shock. An automatic machine applies a precise, controlled feed rate. This prevents the drill from being forced through the glass too quickly. It also manages a constant and copious flow of coolant to the drill site. This dissipates heat and prevents the thermal stress that can cause glass to shatter. By controlling these variables perfectly, the machine makes the drilling process much more stable and predictable.

Benefit 4: How Does it Lead to Superior Hole Quality and Less Waste?

A major automatic glass drilling machine benefit is a tangible improvement in the quality of the final product and a corresponding reduction in material waste. The technology is designed to produce a perfect hole every time. This consistency directly translates into a lower scrap rate, which has a significant positive impact on a workshop's bottom line. The cost of wasted material is a major expense in glass fabrication.

How Does Counter-Drilling Prevent Exit Chipping?

The counter-drilling technique used by dual-head machines is the ultimate solution for preventing exit chipping, also known as "breakout." Breakout is the chipping that occurs on the back side of the glass as a single drill bit punches through. In a counter-drilling system, the two opposing drills meet in the middle. The drill on the exit side provides physical support to the glass as the first drill completes its path. This prevents the glass from flexing and chipping away. The result is a perfectly clean, chip-free hole on both sides of the glass.

Why is Consistent Coolant Delivery So Important for Quality?

Consistent coolant delivery is vital for quality. The coolant, typically water, prevents the buildup of heat that causes micro-fractures around the hole. A well-designed automatic machine delivers a high volume of coolant directly to the cutting zone. Many advanced systems use "through-the-spindle" coolant. This delivers the water through the center of the rotating drill bit. This ensures the coolant reaches the very tip of the tool, even deep inside a hole. This superior cooling results in a cleaner cut with a smoother internal finish.

How Does Precision Reduce Material Scrap Rates?

Precision directly reduces scrap rates by eliminating errors. A manually drilled hole that is misplaced by a few millimeters may cause the entire piece of expensive glass to be rejected. An automatic machine's ability to place every hole in the exact correct position, time after time, virtually eliminates these types of errors. The reduction in chipping and breakage also contributes to a lower scrap rate. This improved yield on raw materials is a significant and often underestimated financial benefit of automation.

How Does an Automatic Machine Expand a Workshop's Capabilities?

Investing in an automatic glass drilling machine is not just about doing the same work faster. It is about expanding a workshop's capabilities. It allows a business to take on more complex, higher-value work that would be difficult or impossible with manual methods. This ability to offer more sophisticated products is a key driver for growth and market differentiation.

How Does it Enable Complex Hole Patterns?

An automatic machine, with its CNC control, can be programmed to produce highly complex and intricate hole patterns with perfect accuracy. This could be a decorative pattern for an architectural feature or a precise grid of holes for a specialized industrial component. The ability to quickly and accurately reproduce these complex patterns opens up new markets for a workshop. It allows them to move beyond simple, functional drilling into the realm of custom, high-design fabrication.

What is the Advantage of Integrated Milling?

Many modern automatic drilling machines are actually multi-functional CNC drilling and milling machines for glass. In addition to drilling round holes, they can use a milling tool to create non-circular shapes. This includes rectangular cutouts for electrical outlets, notches for hardware, or slots for fittings. This integrated capability is a massive advantage. It allows a workshop to produce a complete, complex part in a single setup. This is a key part of improving overall drilling, cutting, and grinding efficiency.

How Does it Allow for a Wider Range of Materials?

An automatic machine provides the process control needed to successfully drill a wider range of glass types and thicknesses. The operator can create and save specific programs with optimized speeds and feed rates for different materials. This could be a program for standard float glass, another for thicker laminated glass, and another for delicate decorative glass. This ability to easily switch between optimized settings ensures the best possible result on any material. This versatility is a hallmark of a professional-grade glass processing machine overview.

Conclusion

The array of automatic glass drilling machine benefits makes a compelling case for its adoption in any serious glass fabrication workshop. It is far more than just a faster way to drill holes. It is a strategic investment in precision, quality, safety, and capability. By eliminating human error, reducing material waste, and dramatically increasing throughput, this technology provides a powerful competitive advantage. It is a foundational piece of equipment that empowers a workshop to produce higher quality work, more efficiently, and more profitably. It is an essential tool for success in the modern glass industry.