Small Glass Beveling Machines: Your 2025 Guide to Precision Glass Edging

Ever admired a glass mirror with a perfectly angled edge or a mosaic tile with a polished bevel that catches the light just right? Those stunning finishes are crafted by small glass beveling machines, compact tools that grind and polish beveled edges on glass with remarkable precision. In 2025, these machines are more affordable and user-friendly than ever, making them a must-have for hobbyists creating custom decor, small workshops producing artisanal glassware, and businesses crafting high-end mirrors or furniture glass. While companies like FUJIAN BAINENG excel in glass processing with tools like their Glass Laser Etching Machine, small glass beveling machines are carving out a niche for precision edging in compact setups.

In this guide, I’ll walk you through everything you need to know about small glass beveling machines. We’ll explore how they work, the different types available, their applications, and how they compare to larger machines or alternative methods like laser engraving. Plus, I’ll share tips to choose the right machine and achieve flawless bevels. Whether you’re a DIY enthusiast or a small business owner, you’re about to unlock the secrets to professional glass edging. Let’s dive in!

What Is a Small Glass Beveling Machine?

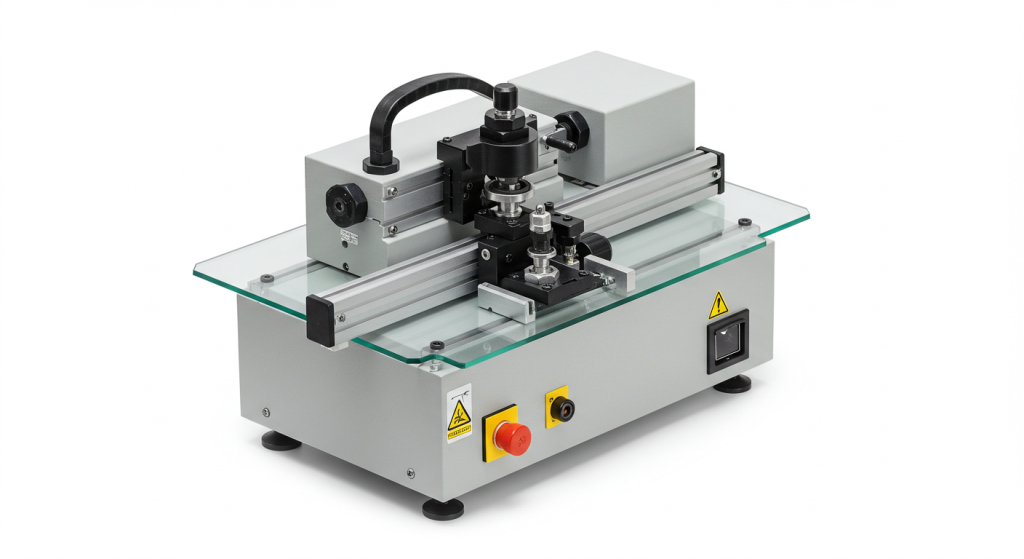

A small glass beveling machine is a compact tool designed to grind and polish angled (beveled) edges on glass, typically for pieces ranging from 15mm x 15mm to 1200mm x 1500mm, with thicknesses from 3mm to 25mm, per BolayMac. These machines create a slanted edge, often at angles of 3° to 45°, enhancing the aesthetic and safety of glass used in mirrors, mosaics, or decorative panels, per CMS Glass Machinery. Unlike larger industrial bevelers, small machines are tailored for workshops with limited space or lower production volumes, offering precision without the bulk.

The machine typically features a series of grinding and polishing wheels (e.g., diamond for rough grinding, resin for fine grinding, felt for polishing) mounted on spindles, a conveyor or table to hold the glass, and a control system—manual, semi-automatic, or PLC-based—for adjusting speed, angle, and bevel width. You secure the glass, set the desired angle and width, and the machine grinds and polishes the edge in one pass, often taking 2-5 minutes for a small piece, per Zhengyi Machinery. Water cooling prevents overheating, and stainless steel components ensure durability in wet environments, per Ervin Sales. From crafting tiny mosaic tiles to polishing mirror edges, these machines deliver professional results in a compact package.

Comparing Small vs. Large Glass Beveling Machines

To decide if a small glass beveling machine is right for you, let’s compare it to large glass beveling machines. Both grind and polish beveled edges, but their size, capacity, and applications differ significantly.

Small Glass Beveling Machines are compact (often under 2m long), designed for workshops with limited space. They handle glass sizes from 15mm x 15mm to 1200mm x 1500mm, with 3-9 spindles for precision on smaller pieces, costing $1,000-$15,000, per Easttec. They’re ideal for artisanal glassware, mosaics, or small-scale mirror production, but less suited for high-volume or oversized glass.

Large Glass Beveling Machines are industrial beasts (3m+ long), built for high-volume production with beds up to 3000mm x 3000mm and 9-13 spindles for faster processing of large panels. They cost $20,000-$100,000 and are used in factories for architectural glass or mass-produced mirrors, per Ervin Sales. They require more space and power but handle heavier workloads.

Here’s a comparison table to clarify:

| Feature | Small Glass Beveling Machine | Large Glass Beveling Machine |

|---|---|---|

| Size | Compact (1-2m long) | Large (3m+ long) |

| Glass Size | 15mm x 15mm to 1200mm x 1500mm | Up to 3000mm x 3000mm |

| Spindles | 3-9 | 9-13 |

| Speed | 0.5-4 m/min | 0.5-6 m/min |

| Cost | $1,000-$15,000 | $20,000-$100,000 |

| Best For | Small workshops, artisanal work | Industrial production, large panels |

Small machines are perfect for precision and flexibility in tight spaces, while large machines dominate high-volume production, per CMS Glass Machinery.

Types of Small Glass Beveling Machines

Small glass beveling machines come in various types, each suited to specific needs, budgets, and skill levels. Here’s a breakdown of the key options in 2025:

Manual Small Glass Beveling Machines

Manual machines, like Easttec’s Hand Glass Beveling Machine, rely on operator control for angle and depth, using 1-3 spindles. They cost $1,000-$3,000 and are ideal for hobbyists or small shops processing glass up to 20mm thick, per Easttec. They’re portable but require skill for consistent results.

Semi-Automatic Small Glass Beveling Machines

Semi-automatic models, like the Ruilong Mini Beveling Machine, feature 3-7 spindles and basic controls (e.g., speed adjustment, manual angle setting), costing $3,000-$8,000. They process glass as small as 60mm x 60mm, perfect for mosaics or crafts, per Ruilong. They balance automation and affordability.

Automatic Small Glass Beveling Machines

Automatic machines, like the Truetec Small Glass Beveling Machine, use PLC or touch-screen controls for precise angle and width settings, with 5-9 spindles. Costing $8,000-$15,000, they handle glass from 30mm x 30mm to 1200mm x 1500mm, ideal for small businesses, per Alibaba. They offer high efficiency with minimal operator input.

Portable Small Glass Beveling Machines

Portable models, like Covington’s Vertical Glass Beveler, are lightweight (under 100 lbs) with 1-2 spindles, costing $1,500-$4,000. They accept 6”-10” wheels and suit on-site work or tiny workshops, processing glass up to 25mm thick, per Covington.

Multi-Function Small Glass Beveling Machines

Multi-function machines, like BolayMac’s Front-Beam Lifting Beveler, combine beveling with bottom edge grinding, using 6-10 spindles. Costing $10,000-$15,000, they process glass as small as 15mm x 15mm, ideal for mosaic or mirror work, per BolayMac.

A semi-automatic or automatic small glass beveling machine is a great starting point for most small workshops, per Easttec.

Applications of Small Glass Beveling Machines

Small glass beveling machines are versatile, serving both creative and commercial purposes. Here are some key applications:

- Mosaic and Craft Glass: Bevel tiny glass pieces (15mm x 15mm) for mosaics or stained glass art, adding sparkle to decor, per Ruilong.

- Mirrors: Create polished beveled edges on mirrors for frames, bathrooms, or boutiques, selling for $50-$300, per BolayMac.

- Glassware: Bevel edges on glassware or vases for a premium finish, popular in artisanal markets, per Etsy.

- Furniture Glass: Process beveled glass for tabletops or cabinet doors, enhancing luxury furniture, per BAINENG.

- Decorative Panels: Bevel small glass panels for wall art or room dividers, used in homes or offices, per CMS Glass Machinery.

- Retail Displays: Bevel glass for branded display cases or shelves, boosting retail aesthetics, per Gravotech.

These applications show how small glass beveling machines create high-value, custom products for profit or passion.

Benefits of Small Glass Beveling Machines

Why choose a small glass beveling machine? Here’s what makes them stand out:

- Compact Design: Fit in small workshops (1-2m long), saving space vs. industrial models, per Easttec.

- Precision: Achieve accurate bevel angles (3°-45°) and widths (up to 60mm), per BolayMac.

- Speed: Process small pieces in 2-5 minutes, boosting productivity for small batches, per OMTech.

- Affordability: Cost $1,000-$15,000, accessible for hobbyists or small businesses, per Alibaba.

- Versatility: Handle glass from 15mm x 15mm to 1200mm x 1500mm, suitable for crafts to panels, per Ruilong.

- Durability: Stainless steel components resist corrosion in wet environments, per Ervin Sales.

A small workshop owner using Easttec’s machine noted, “It’s transformed my mosaic production with perfect bevels in half the time!” These perks make small glass beveling machines a top choice for precision and practicality.

How to Choose the Right Small Glass Beveling Machine

Picking the perfect small glass beveling machine is easier with this step-by-step guide:

- Define Your Project Needs: For mosaics or crafts, a manual or semi-automatic machine like Ruilong’s Mini Beveler works; for small business production, choose an automatic model like Truetec’s, per Ruilong.

- Consider Glass Size and Type: Ensure compatibility with your glass (soda-lime, tempered, mirrors) and size (min 15mm x 15mm, max 1200mm x 1500mm), per BolayMac.

- Set a Budget: Manual machines cost $1,000-$3,000; semi-automatic $3,000-$8,000; automatic $8,000-$15,000, per Easttec.

- Prioritize Features: Look for adjustable spindle angles, PLC/touch-screen controls, and water cooling, per CMS Glass Machinery.

- Check Space Constraints: Ensure the machine (1-2m long) fits your workshop; portable models for tight spaces, per Covington.

- Research Brand Support: Choose brands like Easttec, BolayMac, or Ruilong with reliable service, per Alibaba.

Here’s a quick comparison to guide your choice:

| Machine Type | Glass Size | Spindles | Cost | Best Use |

|---|---|---|---|---|

| Manual (Easttec Hand) | Up to 20mm thick | 1-3 | $1,000-$3,000 | Hobbyists, crafts |

| Semi-Automatic (Ruilong Mini) | 60mm x 60mm+ | 3-7 | $3,000-$8,000 | Mosaics, small shops |

| Automatic (Truetec) | 30mm x 30mm+ | 5-9 | $8,000-$15,000 | Small business production |

A semi-automatic machine is a versatile starting point for most small workshops.

Cost Considerations and ROI

Investing in a small glass beveling machine involves upfront costs, but the return on investment (ROI) can be impressive:

- Cost Breakdown:

- Cost Factors: Spindle count, automation (PLC/touch-screen), and accessories (e.g., water cooling, extra wheels) drive prices.

- ROI Benefits:

- High Margins: Beveled glassware sells for $20-$50; mirrors or panels for $200-$1,000, boosting revenue, per Algolaser.

- Fast Production: Beveling small pieces in 2-5 minutes cuts labor costs, allowing high output.

- Low Operating Costs: Water cooling and durable wheels minimize maintenance, per Ervin Sales.

- Market Demand: Beveled glass for mosaics, mirrors, and furniture is trending in 2025, driving sales.

- Used vs. New: Pre-owned machines from Bavelloni or Easttec can save 20-30%, but verify spindle and wheel condition, per Exapro.

- Financing Options: Suppliers like Easttec or BolayMac offer financing, making higher-end models accessible. Contact suppliers for quotes, as prices vary by region.

A $5,000 semi-automatic machine could pay for itself in months by selling 200 beveled pieces at $50 each, while automatic models yield higher returns for larger orders.

Maintenance and Safety Tips

Keeping your small glass beveling machine in top shape and staying safe are key to consistent, high-quality results. Here’s how:

- Maintenance:

- Clean Spindles and Wheels: Remove glass dust weekly to prevent wear; lubricate spindles monthly, per Ervin Sales.

- Check Water System: Ensure stainless steel tanks and nozzles are clear to maintain cooling, per Zhengyi Machinery.

- Inspect Belts/Conveyors: Verify timing belts or chains for wear; replace if stretched, per BolayMac.

- Safety:

- Wear Protective Gear: Use safety glasses and gloves to shield against glass dust and water spray, per Focused Laser Systems.

- Ensure Proper Ventilation: Ventilate the workspace to remove dust, especially in wet grinding environments, per Gravotech.

- Avoid Overloading: Don’t exceed glass size/weight limits (e.g., 500 lbs for small machines) to prevent spindle strain, per Easttec.

- Troubleshooting:

- Uneven Bevels? Adjust spindle alignment or replace worn wheels.

- Slow Grinding? Check water flow or increase spindle speed.

Maintenance Checklist:

- [ ] Clean spindles/wheels weekly

- [ ] Lubricate spindles monthly

- [ ] Check water system and belts regularly

- [ ] Wear safety gear during operation

- [ ] Verify glass size/weight limits

These steps ensure your machine delivers perfect bevels and lasts for years.

FAQs About Small Glass Beveling Machines

Got questions? Here are answers to common queries about small glass beveling machines:

What glass types can small glass beveling machines process?

Most handle soda-lime (bottles), borosilicate (labware), and tempered glass up to 25mm thick. Avoid lead crystal, which may crack under grinding, per Focused Laser Systems.

How wide can bevels be with these machines?

Bevels typically range from 5mm to 60mm, adjustable via spindle settings, per BolayMac.

Do I need special software for automatic machines?

Yes, PLC or touch-screen systems (e.g., INOVANCE, MCGS) are used for angle/width control, often included, per Zhengyi Machinery.

Are they safe for thin glass?

Yes, with proper water cooling and low pressure, thin glass (3mm+) can be beveled safely, per CMS Glass Machinery.

How long does beveling take?

Small pieces (e.g., 100mm x 100mm) take 2-5 minutes; larger ones (1200mm x 1500mm) may take 5-10 minutes, per OMTech.

Wrapping It Up

Small glass beveling machines are your key to creating stunning, high-value glass designs, from intricate mosaics to polished mirrors and furniture glass. With options like manual machines for hobbyists, semi-automatic for small shops, and automatic models for businesses, there’s a machine for every need. They offer precision, speed, and affordability compared to larger industrial bevelers, making them perfect for compact workshops. Start with a semi-automatic model like Ruilong’s Mini Beveler, keep your wheels clean, and test settings on scrap glass. In 2025, you’re ready to craft beveled edges that elevate your projects, impress clients, or spark creativity.

Ready to start beveling? Explore machines from Easttec, BolayMac, or Ruilong, and share your project ideas in the comments—I’d love to hear what you’re creating!