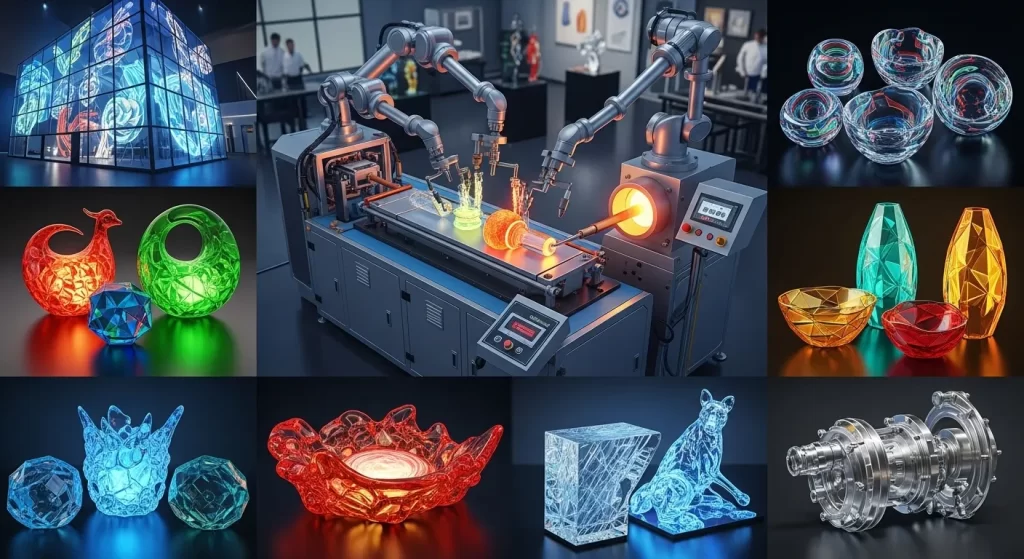

3D Glass Art Machine Applications and Ideas

The scope of 3D glass art machine applications is a testament to a revolutionary technology that has redefined the possibilities of decorative glass. These machines use a sub-surface laser engraving process. This creates intricate, three-dimensional images that appear to float inside a solid block of crystal or glass. This technique has unlocked a vast range of applications. It spans from personalized consumer products to sophisticated architectural and scientific models. This guide provides a definitive exploration of these applications. It details how this innovative technology is used across various industries to create works of exceptional beauty and complexity.

What Defines a 3D Glass Art Machine?

A 3D glass art machine is a specialized piece of equipment that uses a focused laser beam to create marks inside a transparent material. The process, known as sub-surface laser engraving, leaves the exterior of the glass completely untouched. It builds a three-dimensional image point-by-point within the glass block. This creates a unique and captivating visual effect that cannot be replicated by any surface-marking technology.

How Does Sub-Surface Laser Engraving Work?

Sub-surface laser engraving works by focusing a high-intensity laser to a precise point within a block of optical glass. The laser is calibrated to pass harmlessly through the surface. It only delivers enough energy to create a tiny fracture, or dot, at its exact focal point. A computer controls the position of this focal point with incredible speed and accuracy. The machine plots millions of these dots to construct the final 3D image. The process is detailed in our guide on how 3D glass engraving machines work.

What is the Resulting Artistic Effect?

The resulting artistic effect is a three-dimensional image that appears to be suspended inside the clear glass block. The image is composed of millions of tiny, frosted white dots. The density and arrangement of these dots create the illusion of solid shapes, surfaces, and shading. The final piece can be viewed from any angle. This provides a true 360-degree representation of the original 3D model. The effect is often described as magical or ethereal.

How is This Different From Surface Engraving?

This is fundamentally different from surface engraving in its location and appearance. Surface engraving, whether by laser or a physical tool, alters the exterior of the glass. The difference between glass engraving and etching details these surface-level techniques. Sub-surface engraving works entirely inside the material. A surface engraving can be felt. A sub-surface engraving leaves the exterior perfectly smooth.

What Are the Core 3D Glass Art Machine Applications in Personalization?

The core 3D glass art machine applications in the personalization market are vast and highly profitable. This technology allows for the creation of unique, custom keepsakes that capture memories and moments in a three-dimensional format. It has revolutionized the personalized gift industry. It offers a premium product that is both technologically advanced and deeply personal. The demand for unique gifts is a powerful market driver.

How Are 3D Photo Crystals Created?

3D photo crystals are the most popular consumer application. The process begins with a standard 2D photograph. Specialized software is used to convert this flat image into a three-dimensional model. The software creates a depth map, giving the portrait a realistic, volumetric shape. This 3D data is then sent to the engraving machine. The machine then meticulously recreates the portrait inside a block of optical crystal. This creates a lasting and deeply personal memento from a cherished photograph.

What is the Application in Personalized Memorials?

This technology has found a powerful application in the creation of personalized memorials. A photograph of a loved one or a cherished pet can be engraved in 3D inside a crystal block. This creates a beautiful and lasting tribute. These memorials are often displayed in homes on a lighted base, which illuminates the internal engraving. This creates a touching and respectful focal point for remembrance. It is a modern and elegant alternative to traditional memorial plaques.

How is it Used for Custom Trophies and Hobbyist Awards?

For custom trophies and hobbyist awards, 3D engraving offers a unique level of customization. A 3D model of a specific object, such as a classic car, a golf ball, or a musical instrument, can be engraved inside an award block. This creates a highly specific and relevant prize for a competition or event. For gamers, a 3D model of a favorite character or in-game item can be engraved. This level of personalization is far beyond what is possible with standard surface engraving.

What Are Some Unique Personalized Gift Ideas?

The technology opens up a world of unique personalized gift ideas for any occasion.

- Weddings and Anniversaries: A 3D engraving of the couple from a wedding photo is a classic choice.

- Graduations: A 3D model of the school's mascot or a symbol of the graduate's field of study can be engraved.

- Holidays: A 3D model of a family home or a beloved pet can be transformed into a beautiful holiday keepsake.

- New Baby: A 3D rendering of a baby's handprint or footprint can be engraved inside a crystal block. These gifts are valued for their uniqueness and the high level of thought and effort they represent.

How is This Technology Used in Corporate Branding and Recognition?

In the corporate world, this technology is used to create premium awards, gifts, and promotional items. The sophisticated, high-tech appearance of a sub-surface engraving aligns perfectly with the image of modern, innovative companies. It is a powerful tool for employee recognition, client appreciation, and high-end branding. The market for corporate awards is a significant driver of this technology's adoption.

Why Are 3D Engraved Awards a Premium Choice?

3D engraved awards are a premium choice because they convey a sense of quality, prestige, and innovation. A company's logo or a new product can be modeled in 3D. This model can then be engraved inside a flawless block of optical crystal. This creates a stunning, multi-dimensional award that is far more impactful than a simple surface-engraved plaque. The weight and clarity of the crystal, combined with the intricate internal image, make it a true object of art. This is a high-end application of glass engraving for decor and branding.

How Are Corporate Logos and Products Modeled in 3D?

Corporate logos and products are modeled in 3D using specialized software. A graphic designer or 3D artist takes a standard 2D logo or a series of product photographs. They then use 3D modeling software to build a digital, three-dimensional representation. This requires skill and artistry. The artist must interpret the 2D design and give it a realistic sense of depth and form. This digital model is the blueprint for the final engraved piece. High-quality modeling is a key part of the process.

What Are the Applications for Financial Tombstones and Deal Toys?

In the financial industry, "deal toys" or "financial tombstones" are commemorative awards. They are given to celebrate the closing of a major business transaction. 3D sub-surface engraving is the premier technology for creating these items. A 3D model of a company's headquarters, a new product, or an abstract representation of the deal can be engraved. This creates a highly customized and impressive memento for the executives involved in the transaction.

How is it Used for High-End Promotional Items?

For high-end promotional items, 3D engraving offers a way to create a lasting impression. A company can create 3D engraved paperweights or desk ornaments featuring their logo. These are often given to key clients or at exclusive corporate events. Unlike a standard promotional item that may be quickly discarded, a 3D crystal engraving is a beautiful object. It is likely to be kept and displayed for years. This provides a long-lasting branding opportunity.

What Are the Architectural 3D Glass Art Machine Applications?

The architectural 3D glass art machine applications are an exciting and growing field. As the technology evolves to handle larger pieces of glass, architects and interior designers are beginning to incorporate sub-surface engraving into their projects. This allows them to use glass not just as a transparent barrier, but as a medium for large-scale art and decorative patterns. This is a true innovation in architectural design.

How is it Used for Decorative Interior Panels and Partitions?

The technology is being used to create stunning decorative panels and partitions. An entire wall or room divider can be made from a series of large glass blocks. Each block can be engraved with a part of a larger, abstract pattern. When the blocks are assembled, they form a massive, continuous 3D image within the glass wall. This creates a spectacular focal point. It also allows light to pass through, maintaining a sense of openness. This is one of the most exciting glass engraving ideas for architecture.

What is the Application in Artistic Lighting Fixtures?

In lighting design, 3D engraving can be used to create unique and beautiful effects. An abstract pattern or texture can be engraved inside a glass block or sphere. When this block is illuminated from within by LEDs, the internal engraved points catch and scatter the light. This creates a captivating, three-dimensional glow. This technique can be used to create custom chandeliers, sconces, and other artistic lighting fixtures. The interaction between the internal engraving and the light source is key.

How Can it Be Used for Custom Architectural Signage?

For high-end architectural signage, 3D sub-surface engraving offers a sophisticated alternative to surface marking. A building's name or a corporate logo can be engraved inside a thick block of glass. This block can then be mounted and edge-lit. The light will be trapped within the glass and will cause the internal 3D logo to glow brilliantly. This creates a very modern, elegant, and durable sign that is protected from the elements.

What Are the Challenges of Large-Scale Architectural Projects?

The primary challenge of large-scale architectural projects is the size and weight of the glass. 3D engraving machines have physical limitations on the size of the block they can accommodate. Creating very large installations often requires engraving multiple smaller blocks and then assembling them. This requires incredible precision in both the engraving and the installation. The cost of the optically pure glass required for these projects can also be substantial.

What Are the Scientific and Technical Applications?

Beyond the world of art and design, this technology has found a number of fascinating and valuable scientific and technical applications. The ability to create a precise, permanent 3D model inside a solid block is a powerful tool for visualization and education in a number of complex fields.

How is it Used for 3D Data Visualization?

The technology is an excellent tool for 3D data visualization. Scientists can take complex data sets, such as a weather pattern, a geological survey, or a stellar constellation, and represent them as a 3D point cloud. This point cloud can then be engraved inside a crystal block. This creates a permanent, tangible, and intuitive physical model of the abstract data. This can be an invaluable aid for research, presentation, and education.

What is the Application in Medical and Anatomical Modeling?

In the medical field, the technology is used to create detailed anatomical models. A 3D model can be generated from a CT or MRI scan. This model, which could be of a human organ, a bone structure, or a tumor, can then be engraved in 3D inside a block of glass. Doctors and medical students can then view and study this complex anatomical structure from any angle. It is a powerful tool for surgical planning and patient education.

How Are Engineering and Molecular Models Created?

Engineers and chemists use the technology to create physical models of their designs. An engineer can take a complex CAD model of a new machine part or an engine and have it engraved in 3D. A chemist can take a 3D model of a complex protein or drug molecule and create a physical representation. These crystal models are far more durable and sophisticated than traditional plastic models. They are excellent for presentations to clients or stakeholders.

Why is a Physical 3D Model Superior for Presentations?

A physical 3D model is often superior for presentations because it is tangible and intuitive. A complex 3D image on a 2D computer screen can be difficult to interpret. A physical model that can be held, turned, and viewed from all sides provides a much clearer and more immediate understanding of the object's form and structure. The high-end, sophisticated look of a 3D crystal model also adds a sense of importance and value to the presentation.

What Are Some Innovative and Creative 3D Glass Art Ideas?

The artistic potential of the technology is still being explored. As artists and designers become more familiar with the medium, they are developing innovative and creative new ideas. These new approaches push the boundaries of what is possible. They combine the precision of the machine with the boundless creativity of the human imagination. These are the engraving-etching-innovations that are defining the future of the art form.

How Can Artists Create Abstract Sub-Surface Sculptures?

Artists are using 3D modeling software to create purely abstract digital sculptures. These are not representations of real-world objects. They are explorations of form, texture, and light. These abstract models are then engraved inside large blocks of optical crystal. The resulting pieces are captivating sculptures made of light and shadow, permanently frozen within the glass. The interplay between the transparent medium and the frosted, internal form is a powerful artistic statement.

What is the Potential of Combining 3D Engraving with Other Techniques?

A highly advanced and creative approach is to combine sub-surface engraving with other glass decorating techniques. For example, an abstract 3D form could be engraved inside a glass block. The surface of that same block could then be etched with a frosted pattern or sand-carved with a deep texture. This combination of internal and external decoration creates a piece with incredible depth, complexity, and tactile interest. This requires a mastery of multiple techniques, including the methods described in the difference between glass engraving and etching guide.

How Can Lighting Be Used to Enhance 3D Glass Art?

Lighting is a critical element in the display of 3D glass art. The internal engraved points are most visible when they are illuminated. A simple LED light base can dramatically enhance the appearance of a 3D engraving. It causes the internal image to glow brightly. Artists and designers are creating custom lighting systems that use colored or programmable LEDs. This can change the color and intensity of the illumination, creating dynamic and interactive art pieces.

Conclusion

The wide range of 3D glass art machine applications demonstrates the profound impact of this technology. From deeply personal photo crystals to large-scale architectural installations and complex scientific models, sub-surface laser engraving has opened up a new dimension in glass artistry. It has transformed a simple, transparent material into a canvas for three-dimensional creation. By understanding the technology and exploring its diverse applications, designers, artists, and entrepreneurs can continue to find new and innovative ways to capture light, form, and imagination inside the timeless medium of glass.